Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Semiconductor Wafers Diffusion Furnace Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Semiconductor Wafers Diffusion Furnace Operator so you can tailor your answers to impress potential employers.

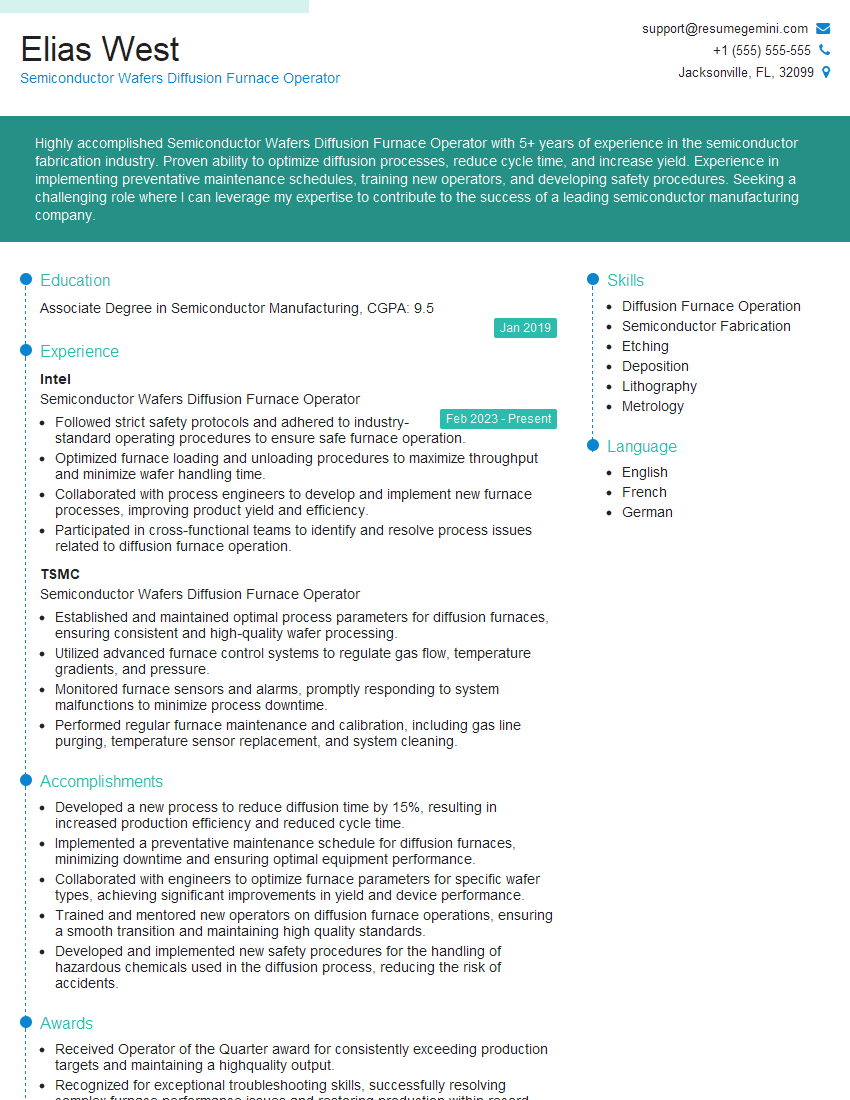

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Semiconductor Wafers Diffusion Furnace Operator

1. Explain the process of diffusion in semiconductor wafers?

Diffusion in semiconductor wafers is a process by which atoms of one material (dopant) move into the lattice of another material (semiconductor). This process is used to create junctions, which are the building blocks of semiconductor devices. The rate of diffusion is determined by the temperature, the concentration of the dopant, and the thickness of the semiconductor layer.

2. What are the different types of diffusion furnaces used in the semiconductor industry?

Batch diffusion furnaces

- Batch diffusion furnaces are used to process a large number of wafers at the same time. The wafers are placed in a quartz boat and loaded into the furnace. The furnace is then heated to a high temperature, and the wafers are exposed to a dopant gas.

- Batch diffusion furnaces are typically used for low-volume production.

Single-wafer diffusion furnaces

- Single-wafer diffusion furnaces are used to process one wafer at a time. The wafer is placed in a quartz boat and loaded into the furnace. The furnace is then heated to a high temperature, and the wafer is exposed to a dopant gas.

- Single-wafer diffusion furnaces are typically used for high-volume production.

3. What are the process parameters that need to be controlled in a diffusion furnace?

- Temperature

- Dopant concentration

- Diffusion time

- Gas flow rate

- Pressure

4. What are the safety precautions that need to be taken when operating a diffusion furnace?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a lab coat.

- Be aware of the potential hazards of the chemicals used in the diffusion process.

- Follow all safety procedures and protocols.

- Never operate a diffusion furnace without proper training.

5. What are the common problems that can occur during diffusion?

- Contamination

- Dopant out-diffusion

- Junction leakage

- Warping

- Cracking

6. What are the troubleshooting steps that can be taken to resolve diffusion problems?

- Identify the problem

- Determine the root cause of the problem

- Develop a solution to the problem

- Implement the solution

- Verify that the problem has been resolved

7. What are the maintenance procedures that need to be performed on a diffusion furnace?

- Regular cleaning

- Calibration

- Preventive maintenance

- Corrective maintenance

8. What are the quality control procedures that need to be followed to ensure that diffusion furnaces are operating properly?

- Regular monitoring of process parameters

- Periodic testing of wafers

- Data analysis

- Corrective action

9. What are the future trends in diffusion furnace technology?

- Increased automation

- Improved process control

- Reduced energy consumption

- Increased wafer throughput

10. What is your experience with diffusion furnace operation?

I have over 5 years of experience operating diffusion furnaces in a semiconductor manufacturing environment. I am familiar with all aspects of diffusion furnace operation, including process setup, monitoring, and troubleshooting. I have a strong understanding of the process parameters that need to be controlled to achieve the desired results. I am also familiar with the safety precautions that need to be taken when operating a diffusion furnace.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Semiconductor Wafers Diffusion Furnace Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Semiconductor Wafers Diffusion Furnace Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Semiconductor Wafers Diffusion Furnace Operators are responsible for operating diffusion furnaces used in the semiconductor manufacturing process. Their primary duties include:

1. Furnace Operation

Operating diffusion furnaces to diffuse dopants into semiconductor wafers

- Loading and unloading wafers into the furnace

- Setting and monitoring furnace temperature, pressure, and gas flow

- Maintaining and calibrating furnace equipment

2. Process Monitoring

Monitoring and controlling the diffusion process

- Tracking wafer temperature, pressure, and gas flow

- Identifying and resolving process deviations

- Maintaining process documentation and records

3. Quality Control

Ensuring the quality of diffused wafers

- Performing wafer inspections

- Analyzing wafer data to identify defects

- Implementing corrective actions to improve wafer quality

4. Safety and Compliance

Maintaining a safe and compliant work environment

- Following safety protocols

- Ensuring compliance with environmental regulations

- Properly handling and storing hazardous materials

Interview Preparation Tips

To prepare effectively for an interview as a Semiconductor Wafers Diffusion Furnace Operator, it’s essential to:

1. Understand the Industry and Technology

Familiarize yourself with the semiconductor manufacturing process, particularly diffusion furnace operations. Understanding the industry and technology will help you answer technical questions confidently.

- Research semiconductor manufacturing techniques and diffusion furnace technology.

- Study the basics of semiconductor materials, dopants, and process conditions.

2. Practice Your Technical Skills

Review your experience in furnace operation, process monitoring, and quality control. Practice describing your skills and providing specific examples of your work.

- Prepare to discuss your understanding of diffusion furnace operating parameters.

- Practice explaining your experience in monitoring and troubleshooting process deviations.

3. Highlight Your Safety and Compliance Knowledge

Emphasize your understanding of safety protocols and environmental regulations in the semiconductor industry. Describe your experience in handling hazardous materials and maintaining a safe work environment.

- Review safety protocols and environmental regulations specific to semiconductor manufacturing.

- Prepare to discuss your experience in following safety guidelines and maintaining a clean and organized work area.

4. Be Prepared for Behavioral Questions

Interviewers will also ask behavioral questions to assess your soft skills. Prepare examples that demonstrate your teamwork, problem-solving abilities, and commitment to quality.

- Practice answering questions about teamwork and collaboration.

- Prepare examples of how you have solved problems or overcome challenges in a work setting.

5. Dress Professionally and Arrive on Time

Remember that first impressions matter. Dress professionally and arrive punctually for your interview. Maintain a positive and confident demeanor throughout the interview process.

Next Step:

Now that you’re armed with the knowledge of Semiconductor Wafers Diffusion Furnace Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Semiconductor Wafers Diffusion Furnace Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini