Are you gearing up for an interview for a Semiconductor Wafers Marker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Semiconductor Wafers Marker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

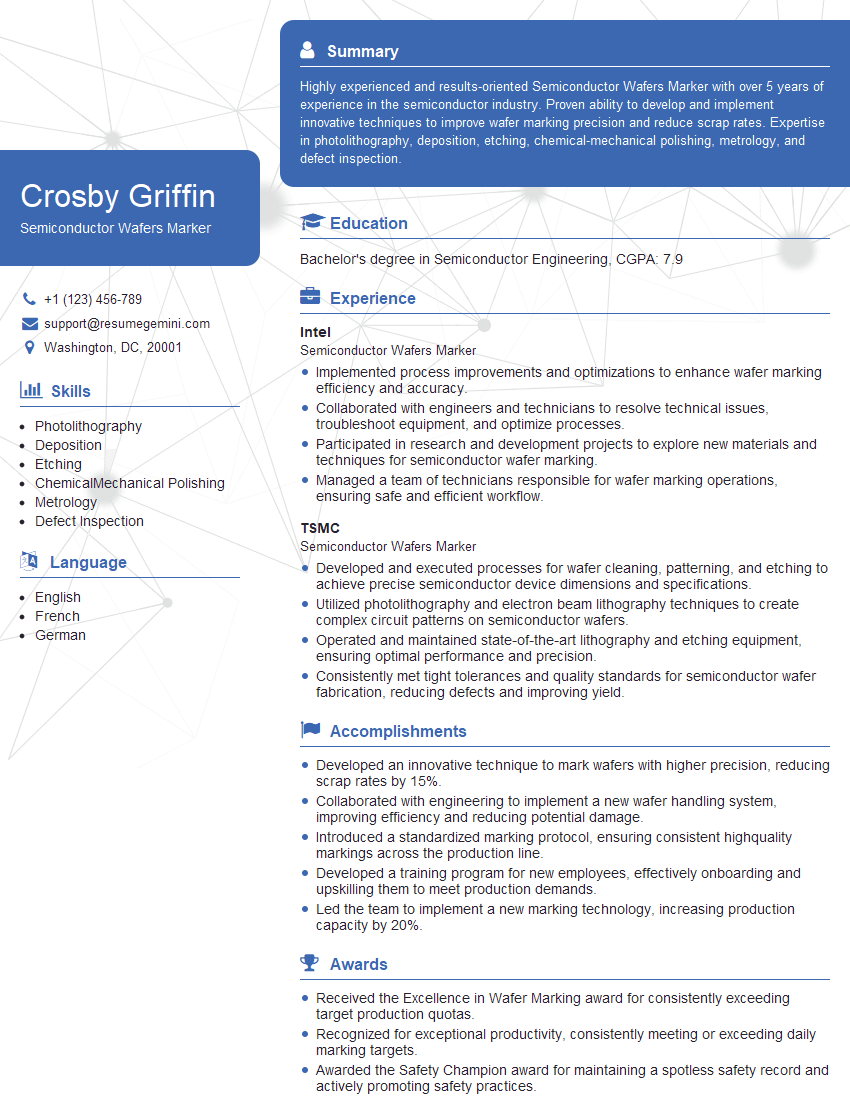

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Semiconductor Wafers Marker

1. What are the main steps involved in the semiconductor wafer manufacturing process?

The main steps involved in the semiconductor wafer manufacturing process are:

- Wafer fabrication

- Wafer cleaning

- Wafer inspection

- Wafer etching

- Wafer deposition

- Wafer lithography

- Wafer packaging

2. What are the properties of a high-quality semiconductor wafer?

- High purity

- Low defect density

- Good surface finish

- Uniform thickness

- Consistent crystal structure

3. What are the challenges in semiconductor wafer manufacturing?

- Achieving high yields

- Controlling contamination

- Maintaining precision

- Reducing costs

- Meeting environmental regulations

4. What are the trends in semiconductor wafer manufacturing?

- Increasing wafer size

- Using new materials

- Developing new processes

- Automating manufacturing

- Improving quality control

5. What are the applications of semiconductor wafers?

- Integrated circuits

- Solar cells

- Light-emitting diodes (LEDs)

- Transistors

- Diodes

6. What are the different types of semiconductor materials used in wafer manufacturing?

- Silicon

- Gallium arsenide

- Indium phosphide

- Gallium nitride

- Silicon carbide

7. What are the different types of defects that can occur in semiconductor wafers?

- Point defects

- Line defects

- Planar defects

- Bulk defects

- Surface defects

8. What are the different methods used to inspect semiconductor wafers?

- Optical inspection

- Electrical inspection

- Acoustic inspection

- X-ray inspection

- Scanning electron microscopy (SEM)

9. What are the different methods used to clean semiconductor wafers?

- Chemical cleaning

- Physical cleaning

- Plasma cleaning

- UV ozone cleaning

- Megasonic cleaning

10. What are the different methods used to etch semiconductor wafers?

- Wet etching

- Dry etching

- Plasma etching

- Reactive ion etching (RIE)

- Deep reactive ion etching (DRIE)

11. What are the different methods used to deposit materials on semiconductor wafers?

- Physical vapor deposition (PVD)

- Chemical vapor deposition (CVD)

- Molecular beam epitaxy (MBE)

- Atomic layer deposition (ALD)

- Electrochemical deposition (ECD)

12. What are the different methods used to lithographically pattern semiconductor wafers?

- Photolithography

- Electron beam lithography (EBL)

- X-ray lithography

- Extreme ultraviolet (EUV) lithography

- Nanoimprinting lithography (NIL)

13. What are the different methods used to package semiconductor wafers?

- Wire bonding

- Flip chip bonding

- Ball grid array (BGA) packaging

- Quad flat pack (QFP) packaging

- Plastic quad flat pack (PQFP) packaging

14. What are the different quality control tests that are performed on semiconductor wafers?

- Electrical testing

- Physical testing

- Chemical testing

- Environmental testing

- Reliability testing

15. What are the different safety precautions that must be taken when working with semiconductor wafers?

- Wear cleanroom clothing

- Use proper handling techniques

- Avoid contamination

- Follow proper storage procedures

- Dispose of wafers properly

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Semiconductor Wafers Marker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Semiconductor Wafers Marker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Semiconductor Wafers Markers play a critical role in the fabrication of integrated circuits (ICs) by marking wafers with precise patterns and alignment marks required for subsequent processing steps.

1. Wafer Preparation and Loading

Prepare wafers for marking by cleaning, degreasing, and applying photoresist

- Load wafers onto the marking machine

- Align wafers using lasers or other alignment systems

2. Marking Operations

Operate laser or other marking equipment to create precise patterns and alignment marks

- Control marking parameters, such as laser power and focus

- Monitor marking process to ensure accuracy and quality

3. Inspection and Quality Control

Inspect marked wafers using optical microscopes or other inspection tools

- Verify pattern accuracy, alignment, and quality

- Document inspection results and identify any defects

4. Equipment Maintenance and Calibration

Perform routine maintenance and calibration of marking equipment

- Troubleshoot and resolve equipment issues

- Maintain a clean and organized work area

Interview Tips

To ace an interview for a Semiconductor Wafers Marker position, it is crucial to prepare adequately. Here are some tips to help you succeed:

1. Research the Company and Role

Thoroughly research the company and the specific role you are applying for

- Visit the company website and familiarize yourself with their products, services, and culture

- Read industry publications and articles to stay up-to-date with the latest advancements in semiconductor technology

2. Highlight Your Technical Skills

Emphasize your technical skills and experience in semiconductor wafer marking

- Describe your proficiency in operating laser or other marking equipment

- Share examples of your ability to monitor marking processes and ensure quality

3. Demonstrate Problem-Solving Abilities

Showcase your problem-solving skills by providing examples from your work experience

- Describe situations where you encountered challenges in wafer marking and how you resolved them

- Explain your approach to troubleshooting and maintaining equipment

4. Emphasize Your Attention to Detail

Highlight your attention to detail and your commitment to quality

- Discuss your experience in inspecting marked wafers and identifying defects

- Describe your approach to maintaining a clean and organized work area

5. Prepare Questions for the Interviewer

Prepare thoughtful questions that demonstrate your interest in the company and the role

- Ask about the company’s growth plans and the role of the Semiconductor Wafers Marker in the organization

- Inquire about opportunities for professional development and advancement

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Semiconductor Wafers Marker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!