Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Semiconductor Wafers Photographic Aligner interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Semiconductor Wafers Photographic Aligner so you can tailor your answers to impress potential employers.

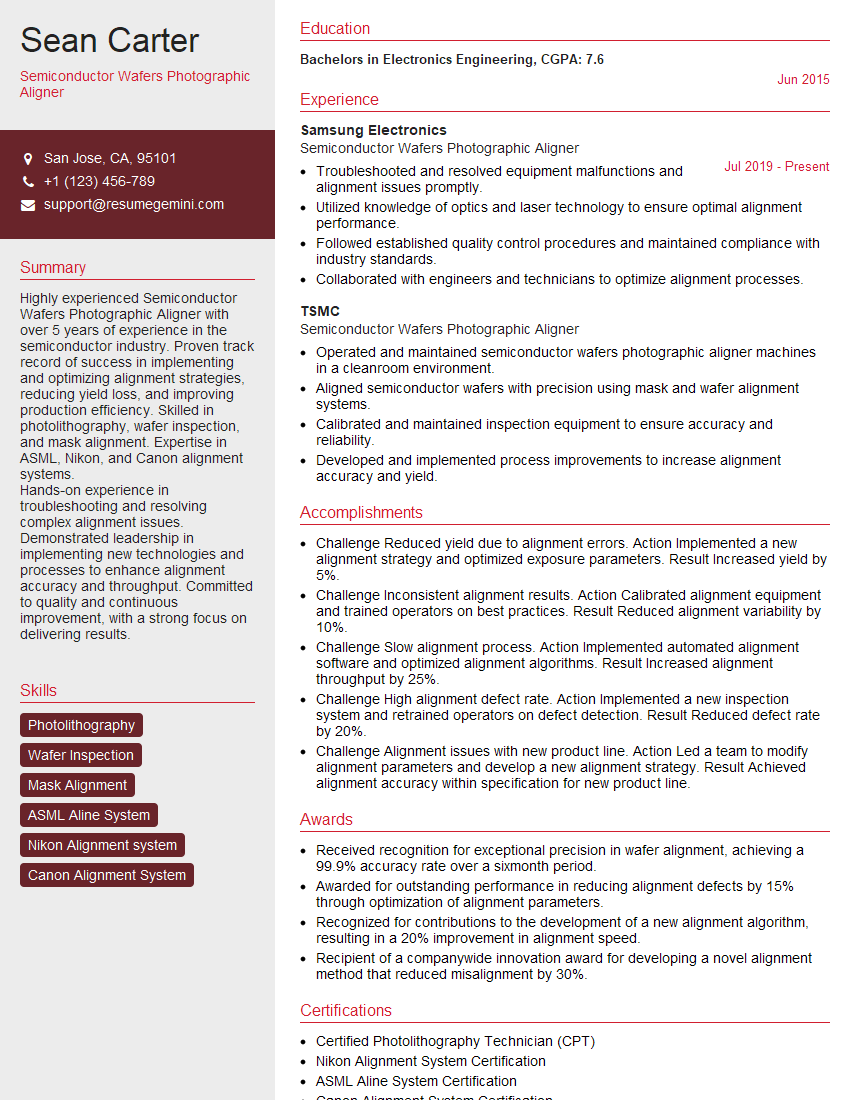

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Semiconductor Wafers Photographic Aligner

1. What is the difference between a contact aligner and a step-and-repeat aligner?

- In contact aligner, the mask is brought into direct contact with the wafer, while in step-and-repeat aligner, the mask is held at a fixed distance from the wafer.

- Contact aligners are cheaper and simpler to operate, but they can only be used with thin wafers. Step-and-repeat aligners are more expensive and complex to operate, but they can be used with wafers of any thickness.

2. What are the different types of light sources used in photolithography?

- The most common type of light source used in photolithography is the mercury lamp. Mercury lamps emit ultraviolet light at a wavelength of 365 nm, which is the wavelength that is best absorbed by photoresist.

- Other types of light sources that can be used in photolithography include excimer lasers, which emit ultraviolet light at a wavelength of 193 nm, and deep-ultraviolet (DUV) lasers, which emit ultraviolet light at a wavelength of 248 nm.

of the answer: Advantages and disadvantages of different light sources

- Mercury lamps are relatively inexpensive and easy to operate, but they have a short lifespan and they can only be used with wafers that are less than 100 nm thick.

- Excimer lasers are more expensive and complex to operate than mercury lamps, but they have a longer lifespan and they can be used with wafers of any thickness.

- DUV lasers are the most expensive and complex type of light source used in photolithography, but they have the shortest wavelength and they can be used to create the smallest features.

3. What are the different types of photoresists used in photolithography?

- Positive photoresist is the most common type of photoresist. It is made of a polymer that is soluble in an alkaline developer. When positive photoresist is exposed to light, the polymer becomes cross-linked and insoluble.

- Negative photoresist is less common than positive photoresist. It is made of a polymer that is soluble in an organic developer. When negative photoresist is exposed to light, the polymer becomes insoluble.

4. What are the different types of alignment marks used in photolithography?

- Cross-shaped alignment marks are the most common type of alignment mark. They are made of a thin layer of metal that is deposited on the wafer.

- Circular alignment marks are also common. They are made of a thin layer of photoresist that is patterned on the wafer.

5. What are the different types of alignment methods used in photolithography?

- Contact alignment is the simplest type of alignment method. The mask is brought into direct contact with the wafer, and the alignment marks are used to align the mask to the wafer.

- Proximity alignment is similar to contact alignment, but the mask is held at a small distance from the wafer. This prevents the mask from damaging the wafer.

- Step-and-repeat alignment is a more precise type of alignment method. The mask is held at a fixed distance from the wafer, and the wafer is moved under the mask so that the mask can be aligned to the alignment marks on the wafer.

6. What are the different types of errors that can occur in photolithography?

- Alignment errors are the most common type of error in photolithography. They occur when the mask is not properly aligned to the wafer.

- Exposure errors occur when the wafer is not properly exposed to light.

- Development errors occur when the wafer is not properly developed.

- Etching errors occur when the wafer is not properly etched.

7. What are the different ways to improve the resolution of a photolithographic process?

- Use a shorter wavelength light source. The shorter the wavelength, the smaller the features that can be created.

- Use a higher quality mask. A higher quality mask will have fewer defects, which will reduce the number of errors in the photolithographic process.

- Use a better alignment method. A better alignment method will ensure that the mask is properly aligned to the wafer, which will reduce the number of alignment errors.

- Use a more precise exposure system. A more precise exposure system will ensure that the wafer is properly exposed to light, which will reduce the number of exposure errors.

- Use a more precise development system. A more precise development system will ensure that the wafer is properly developed, which will reduce the number of development errors.

- Use a more precise etching system. A more precise etching system will ensure that the wafer is properly etched, which will reduce the number of etching errors.

8. What are the different types of defectoscopy used in photolithography?

- Optical defectoscopy is the most common type of defectoscopy used in photolithography. It uses a light source to illuminate the wafer and a camera to inspect the wafer for defects.

- Electron beam defectoscopy is a more precise type of defectoscopy that uses an electron beam to inspect the wafer for defects.

- Scanning probe microscopy is a type of defectoscopy that uses a sharp probe to scan the surface of the wafer and detect defects.

9. What are the different types of yield improvement techniques used in photolithography?

- Process control is the most important yield improvement technique. It involves monitoring the photolithographic process and making adjustments to ensure that the process is running within specification.

- Defect reduction is another important yield improvement technique. It involves identifying and eliminating the sources of defects in the photolithographic process.

- Yield modeling is a technique that can be used to predict the yield of a photolithographic process. It can be used to identify the critical parameters of the process and to optimize the process for yield.

10. What are the future trends in photolithography?

- The use of shorter wavelength light sources, such as excimer lasers and DUV lasers.

- The use of higher quality masks, such as phase-shift masks and attenuated phase-shift masks.

- The use of more precise alignment methods, such as step-and-scan alignment and overlay alignment.

- The use of more precise exposure systems, such as maskless exposure systems and direct-write exposure systems.

- The use of more precise development systems, such as immersion development systems and spray development systems.

- The use of more precise etching systems, such as dry etching systems and ion beam etching systems.

- The use of new materials, such as low-k dielectric materials and high-k dielectric materials.

- The use of new techniques, such as nanoimprinting lithography and extreme ultraviolet lithography.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Semiconductor Wafers Photographic Aligner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Semiconductor Wafers Photographic Aligner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Semiconductor Wafers Photographic Aligner is responsible for aligning and exposing semiconductor wafers to ultraviolet light in order to create the circuitry on the wafers. This is a critical step in the semiconductor manufacturing process, as the alignment of the circuitry is essential for the proper functioning of the final product.

1. Aligning Wafers

The first step in the photolithography process is to align the wafer to the mask. This is done using a series of precision alignment tools, such as a microscope and a laser interferometer. The wafer is then held in place by a vacuum chuck, which prevents it from moving during exposure.

2. Exposing Wafers to Ultraviolet Light

Once the wafer is aligned, it is exposed to ultraviolet light through a mask. The mask is a transparent sheet with the desired circuit pattern printed on it. The ultraviolet light passes through the mask and exposes the areas of the wafer that are not covered by the mask. These areas will become the active areas of the circuit.

3. Developing and Etching the Wafer

After the wafer has been exposed, it is developed and etched to remove the unexposed areas of the wafer. This creates the circuit pattern on the wafer.

4. Inspecting the Wafer

Once the wafer has been developed and etched, it is inspected to ensure that the circuit pattern is correct. This is done using a variety of inspection tools, such as a microscope and a scanning electron microscope.

Interview Tips

Preparing for an interview for a Semiconductor Wafers Photographic Aligner position can be a daunting task, but by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find this information on the company’s website, in industry publications, or by talking to people who work at the company.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience in the semiconductor industry. Be prepared to talk about your skills and experience in aligning and exposing semiconductor wafers. You should also be prepared to discuss any specific projects that you have worked on.

4. Be Enthusiastic and Positive

The interviewer will be looking for someone who is enthusiastic about working in the semiconductor industry. Be sure to express your passion for this field and your desire to learn and grow. Also, be sure to be positive and upbeat throughout the interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Semiconductor Wafers Photographic Aligner role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.