Are you gearing up for an interview for a Semiconductor Wafers Photographic Processor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Semiconductor Wafers Photographic Processor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

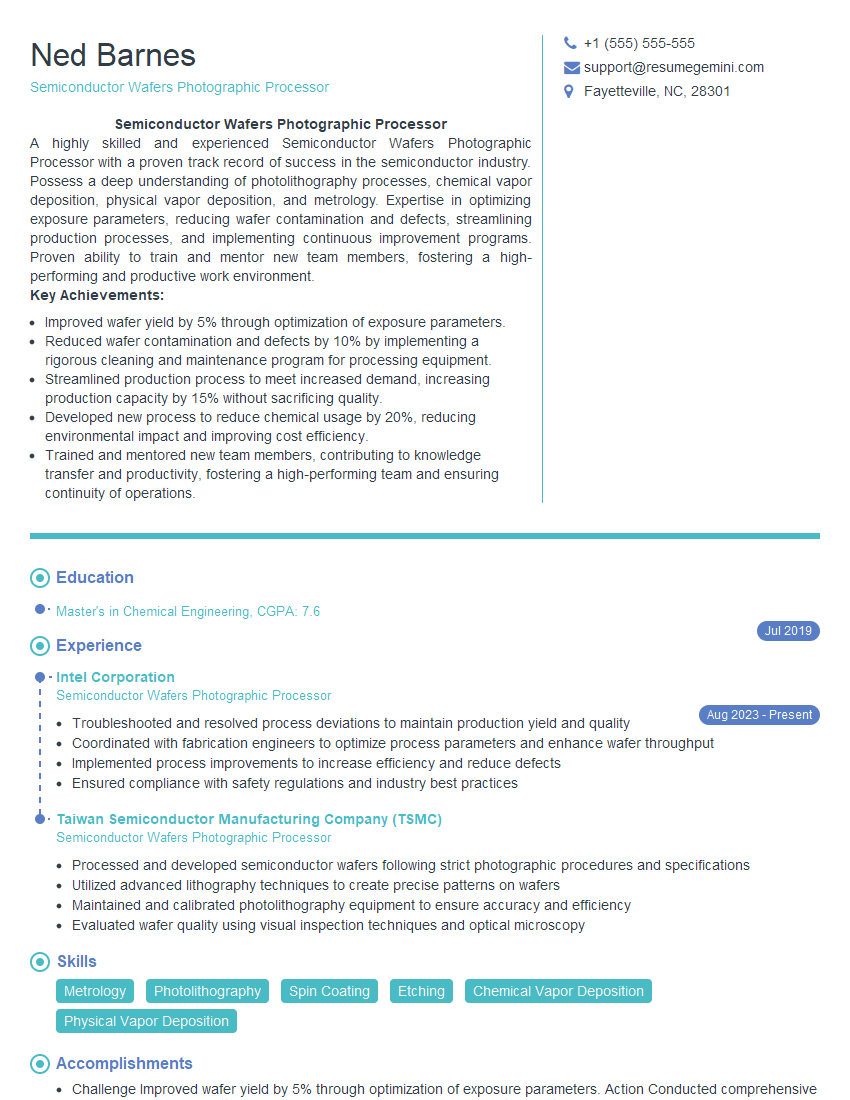

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Semiconductor Wafers Photographic Processor

1. What is the role of a Semiconductor Wafers Photographic Processor?

As a Semiconductor Wafers Photographic Processor, my primary responsibility is to handle the photographic processing of semiconductor wafers, ensuring the creation of high-quality integrated circuits. This includes tasks such as preparing wafers, applying photoresist, exposing them to light, developing and etching patterns, and inspecting the results to ensure they meet specifications.

2. Can you describe the different types of photoresists used in semiconductor manufacturing?

Positive Photoresist

- Exposed areas become soluble and are washed away during development, leaving the unexposed areas protected.

- Used for creating patterns with high resolution and precise dimensions.

Negative Photoresist

- Unexposed areas become soluble and are washed away during development, leaving the exposed areas protected.

- Used for creating thick, high-aspect-ratio structures.

3. What are the critical process parameters involved in photolithography and how do they affect the final product?

Critical process parameters in photolithography include:

- Exposure Dose: Determines the amount of light energy absorbed by the photoresist, influencing pattern resolution and sidewall profiles.

- Development Time: Controls the removal of exposed or unexposed photoresist, affecting pattern dimensions and critical feature sizes.

- Soft Bake Temperature: Prepares the photoresist for exposure by removing solvents and improving adhesion to the wafer.

- Hard Bake Temperature: Hardens the developed photoresist, making it resistant to etching and subsequent processing.

4. How do you ensure the cleanliness of wafers before and after processing?

Wafer cleanliness is crucial for successful processing. I follow strict protocols to ensure it, including:

- Pre-cleaning wafers with solvents to remove surface contaminants.

- Using ultra-pure water for rinsing and cleaning throughout the process.

- Maintaining a cleanroom environment with controlled temperature, humidity, and particle levels.

- Performing regular equipment maintenance and calibration to prevent contamination.

5. What techniques do you use to inspect wafers for defects and ensure pattern accuracy?

I utilize various inspection techniques to ensure wafer quality:

- Optical Microscopy: Inspecting wafers under a microscope to detect visible defects such as scratches, pinholes, or contamination.

- Automated Optical Inspection (AOI): Using specialized equipment to scan wafers for defects and compare them to known good patterns.

- Scanning Electron Microscopy (SEM): Analyzing wafers at high magnifications to reveal surface topography and identify sub-micron defects.

- Electrical Testing: Performing electrical measurements on patterned wafers to assess the functionality of integrated circuits.

6. What is the difference between wet etching and dry etching, and when are each used?

Wet Etching

- Uses liquid etchants to dissolve exposed areas of the wafer.

- Provides isotropic etching, resulting in undercutting and sidewall erosion.

- Suitable for removing thick layers and creating large structures.

Dry Etching

- Uses plasma or reactive gases to etch exposed areas of the wafer.

- Provides anisotropic etching, resulting in vertical sidewalls and precise pattern definition.

- Suitable for creating fine features and high aspect ratio structures.

7. How do you handle and store wafers to prevent damage and contamination?

To prevent damage and contamination, I follow best practices for wafer handling and storage:

- Wear gloves and use wafer carriers: Minimize direct contact with wafers to avoid scratches or fingerprints.

- Store wafers in clean and dry cabinets: Protect wafers from dust, moisture, and temperature fluctuations.

- Label and track wafers: Ensure proper identification and traceability throughout the process.

- Use anti-static measures: Ground equipment and use anti-static materials to prevent electrostatic discharge.

8. What are the safety protocols and regulations you adhere to in the semiconductor manufacturing environment?

I strictly adhere to the following safety protocols and regulations:

- Chemical Safety: Handle and store hazardous chemicals according to safety data sheets and industry standards.

- Electrical Safety: Work with high-voltage equipment and follow lockout/tagout procedures to prevent electrical accidents.

- Cleanroom Safety: Maintain a clean and controlled environment to prevent contamination and protect wafers.

- Personal Protective Equipment (PPE): Wear appropriate PPE such as gloves, lab coats, and safety glasses to minimize exposure to hazards.

9. How do you stay up-to-date with advancements in semiconductor manufacturing technology?

To stay current with industry advancements, I:

- Attend industry conferences and workshops: Engage with experts and learn about new technologies and best practices.

- Read technical journals and research papers: Stay informed about the latest research and developments in the field.

- Participate in continuing education programs: Enhance my skills and knowledge through formal training and certification.

- Network with colleagues and industry professionals: Exchange knowledge and stay connected to the latest trends.

10. Can you describe a challenging situation you faced as a Semiconductor Wafers Photographic Processor and how you overcame it?

In a previous role, we encountered an issue where the developed photoresist patterns were slightly undersized, leading to yield loss. To address this, I:

- Analyzed the process parameters: I carefully reviewed the exposure dose, development time, and soft bake temperature to identify potential deviations.

- Calibrated the equipment: I performed thorough calibration of the exposure tool and developer to ensure accurate and repeatable processing.

- Optimized the process: I fine-tuned the process parameters within the specified tolerances to achieve the desired pattern dimensions.

- Validated the results: I conducted rigorous inspections and electrical testing to confirm the improvement in pattern accuracy and yield.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Semiconductor Wafers Photographic Processor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Semiconductor Wafers Photographic Processor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Semiconductor Wafers Photographic Processor plays a critical role in the semiconductor manufacturing process. Their responsibilities include:

1. Wafer Preparation

Ensures wafers are clean and free of defects before processing.

- Performs wafer cleaning using specialized equipment.

- Inspects wafers for contamination or damage.

2. Photoresist Application

Applies photoresist to wafers using a spin coating machine.

- Selects the appropriate photoresist based on process requirements.

- Controls photoresist thickness and uniformity.

3. Exposure and Development

Exposes wafers to ultraviolet light through a photomask, transferring the circuit pattern onto the photoresist.

- Operates exposure machines and monitors exposure parameters.

- Develops exposed wafers using chemical solutions, removing unexposed photoresist.

4. Pattern Etching

Etches exposed areas of the wafer using plasma or wet etching techniques.

- Selects etch chemistries and controls etch parameters.

- Monitors etch progress and ensures pattern fidelity.

5. Post-Processing

Removes residual photoresist and performs final cleaning to prepare wafers for subsequent processing steps.

- Strips photoresist using solvents or plasma.

- Inspects wafers for defects and contamination.

Interview Tips

To ace the interview, candidates should consider the following:

1. Research the Company and Role

Gather information about the company’s semiconductor manufacturing process and the specific responsibilities of the Semiconductor Wafers Photographic Processor.

- Visit the company’s website and review industry publications.

- Network with professionals in the field.

2. Highlight Technical Skills

Emphasis on your proficiency in photoresist application, exposure and development, etching, and wafer inspection.

- Provide specific examples and quantify your accomplishments.

- Discuss your knowledge of semiconductor manufacturing processes.

3. Demonstrate Attention to Detail

Stress your meticulous nature and ability to follow precise instructions.

- Highlight your experience in cleanroom environments.

- Describe your quality control measures and inspection techniques.

4. Prepare for Common Interview Questions

Anticipate questions related to your technical skills, experience, and motivation.

- Practice answering questions about process optimization, troubleshooting, and safety procedures.

- Explain why you are passionate about the semiconductor industry.

5. Ask Thoughtful Questions

During the interview, ask questions that demonstrate your interest and understanding of the role.

- Inquire about the company’s investment in process automation.

- Ask about opportunities for professional development and career growth.

Next Step:

Now that you’re armed with the knowledge of Semiconductor Wafers Photographic Processor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Semiconductor Wafers Photographic Processor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini