Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Senior Production Planner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

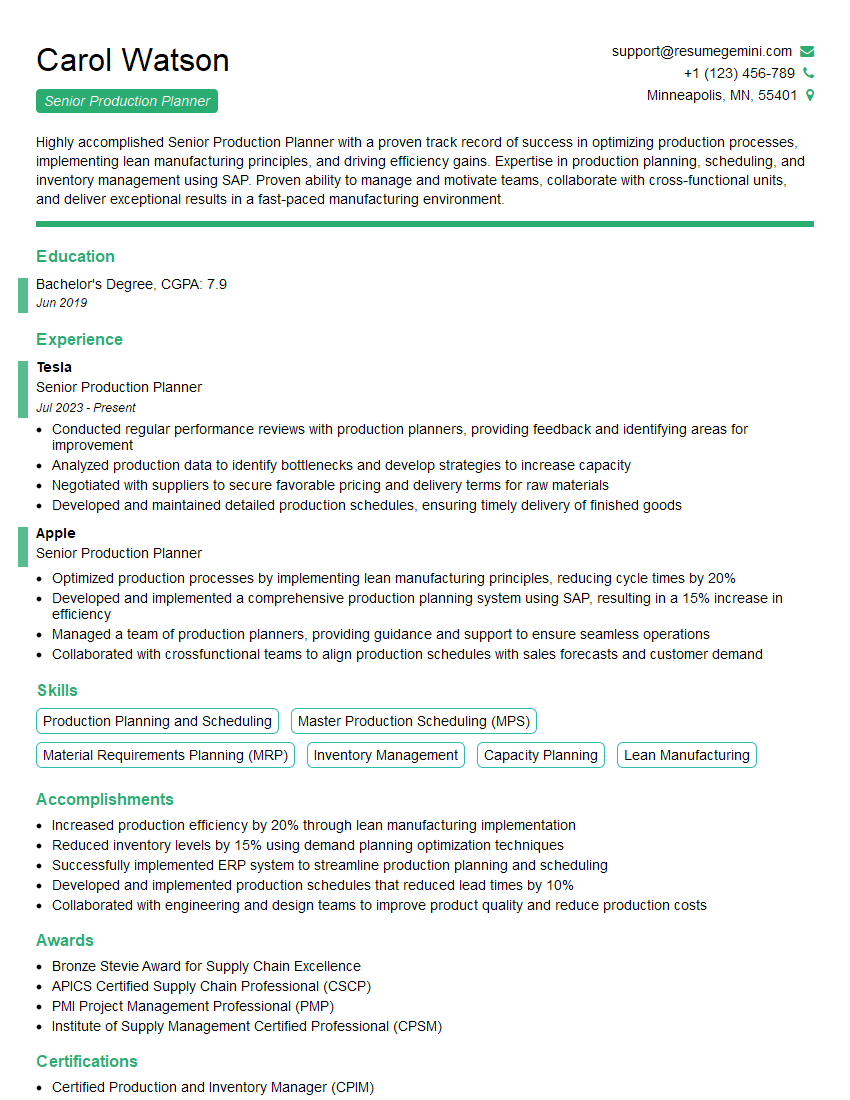

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Senior Production Planner

1. What is the role of a Senior Production Planner in a manufacturing environment?

The role of a Senior Production Planner in a manufacturing environment is to ensure efficient and effective production by planning, organizing, and coordinating all aspects of the production process.

- Develop production schedules that optimize resource utilization and meet customer demand.

- Manage inventory levels to minimize costs and avoid shortages.

- Collaborate with engineering, sales, and purchasing departments to ensure smooth operation.

- Monitor production progress and identify potential bottlenecks or delays.

- Implement continuous improvement initiatives to enhance efficiency and reduce waste.

2. What are the key performance indicators (KPIs) for a Senior Production Planner?

Metrics for Production Efficiency:

- Overall Equipment Effectiveness (OEE)

- Production output vs. Target

- Yield rate (percentage of products that meet quality standards)

Financial KPIs:

- Inventory turnover ratio

- Cost per unit produced

Customer Service KPIs:

- On-time delivery performance

- Customer satisfaction index (CSI)

3. Describe your experience in using production planning software, such as SAP or Oracle ERP.

I have extensive experience in using SAP ERP for production planning and control. I am proficient in modules such as PP (Production Planning), PM (Plant Maintenance), and MM (Materials Management).

- Utilized SAP to create production schedules, manage inventory, and track production progress.

- Implemented MRP (Materials Requirements Planning) to optimize material procurement and minimize inventory waste.

- Integrated SAP with other systems, such as MES (Manufacturing Execution System), to provide real-time production data.

4. How do you approach lean manufacturing principles in your planning process?

I embrace lean manufacturing principles to eliminate waste, improve efficiency, and enhance value for customers. My approach involves:

- Identifying and eliminating non-value-added activities from the production process.

- Streamlining production flow to reduce lead times and minimize work-in-progress.

- Implementing Kanban systems to optimize inventory levels and prevent overproduction.

- Empowering production teams through continuous improvement initiatives.

5. Explain how you would develop a production schedule that balances customer demand with production capacity.

To develop a production schedule that balances customer demand with production capacity, I follow a systematic process that involves:

- Forecasting customer demand through market research and sales data analysis.

- Assessing production capacity, including machine capabilities, labor availability, and material constraints.

- Prioritizing orders based on factors such as due dates, customer importance, and product profitability.

- Using scheduling techniques, such as Gantt charts or critical path analysis, to allocate resources and optimize production flow.

- Monitoring production progress and making necessary adjustments to ensure timely delivery.

6. How do you handle production disruptions, such as equipment breakdowns or material shortages?

In the event of production disruptions, I take a proactive and collaborative approach to minimize their impact on the production schedule.

- Identify the root cause of the disruption and develop a contingency plan to address it.

- Communicate clearly with stakeholders, including production teams, suppliers, and customers, to keep them informed.

- Explore alternative production methods or suppliers to maintain production continuity.

- Prioritize critical orders and reschedule non-critical orders to avoid delays.

- Implement corrective actions to prevent similar disruptions from occurring in the future.

7. Describe a time when you successfully implemented a new production process or technology.

During my tenure at ABC Manufacturing, I led the implementation of a new automated inventory management system. The system integrated with our ERP and provided real-time visibility into inventory levels.

- Collaborated with IT and vendors to configure and deploy the system.

- Trained production staff on the use of the system and its benefits.

- Developed new inventory policies and procedures to optimize stock levels.

- The system resulted in significant improvements in inventory accuracy, reduced stockouts, and increased production efficiency.

8. How do you stay up-to-date with the latest trends and best practices in production planning?

To stay up-to-date with the latest trends and best practices in production planning, I engage in continuous learning and professional development.

- Attend industry conferences and webinars.

- Read trade publications and technical articles.

- Network with other production planners and industry professionals.

- Seek opportunities to implement innovative technologies and methodologies.

9. What are your strengths and weaknesses as a Senior Production Planner?

My strengths as a Senior Production Planner include:

- Proven ability to develop and execute efficient production plans.

- Strong understanding of production processes, lean manufacturing principles, and ERP systems.

- Excellent communication and interpersonal skills for effective collaboration.

- Analytical mindset for problem-solving and continuous improvement.

As for my weaknesses, I would say:

- I am sometimes perceived as being too detail-oriented, which can lead to delays in decision-making.

- I am still developing my experience in managing large-scale production operations.

However, I am committed to addressing these areas through ongoing learning and development.

10. Why are you interested in this Senior Production Planner position?

I am eager to join your organization as a Senior Production Planner because I am confident that my skills and experience align perfectly with the requirements of the role.

- I am particularly drawn to your company’s commitment to operational excellence and continuous improvement.

- I believe that my expertise in production planning and lean manufacturing can contribute significantly to your organization’s success.

- I am eager to take on new challenges and responsibilities and I am confident that I can make a positive impact on your production operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Senior Production Planner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Senior Production Planner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Senior Production Planners play a crucial role in optimizing production processes and ensuring efficient use of resources in a manufacturing environment. Their key responsibilities typically include:

1. Production Planning and Scheduling

- Develop and maintain detailed production schedules that optimize resource allocation, minimize lead times, and meet customer demand.

- Analyze production data, identify bottlenecks, and implement strategies to improve efficiency.

- Collaborate with production teams to ensure adherence to schedules and resolve any production issues.

2. Material Management

- Forecast material requirements, negotiate with suppliers, and manage inventory levels to ensure timely availability of materials.

- Monitor inventory levels and implement inventory control systems to minimize wastage and optimize stock levels.

- Identify and qualify new suppliers to ensure reliable material supply and competitive pricing.

3. Capacity Planning

- Analyze production capacity and identify areas for improvement.

- Develop strategies to increase capacity, optimize resource utilization, and reduce production costs.

- Collaborate with management to make decisions on capital investments and equipment upgrades.

4. Quality Control and Assurance

- Monitor production processes and ensure adherence to quality standards.

- Identify potential quality problems and implement corrective actions.

- Collaborate with quality control teams to develop and maintain quality management systems.

Interview Tips

To ace your interview for a Senior Production Planner role, consider the following tips and prepare accordingly:

1. Research the Company and Role

- Thoroughly research the company’s industry, business model, and products.

- Review the job description carefully and identify the key responsibilities and qualifications required.

- Prepare questions that demonstrate your understanding of the role and company.

2. Highlight Your Technical Skills

- Emphasize your proficiency in production planning tools and techniques.

- Showcase your experience in material management, capacity planning, and quality control.

- Provide examples of how you have used these skills to improve production efficiency and reduce costs.

3. Prepare for Behavioral Questions

- Be prepared to answer behavioral questions that assess your problem-solving, communication, and teamwork skills.

- Use the STAR method (situation, task, action, result) to describe specific situations where you demonstrated these competencies.

- For example, you could share an experience where you successfully resolved a production issue by collaborating with multiple departments.

4. Ask Thoughtful Questions

- Prepare well-thought-out questions to ask the interviewer.

- This demonstrates your interest in the role and company.

- Questions could focus on the company’s growth plans, sustainability initiatives, or opportunities for professional development.

5. Practice Your Presentation

- Practice presenting your skills and experiences in a clear and concise manner.

- You can use a mock interview with a friend or mentor to get feedback and improve your delivery.

- Be confident in your abilities and enthusiastic about the opportunity.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Senior Production Planner, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Senior Production Planner positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.