Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Senior QC Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Senior QC Technician so you can tailor your answers to impress potential employers.

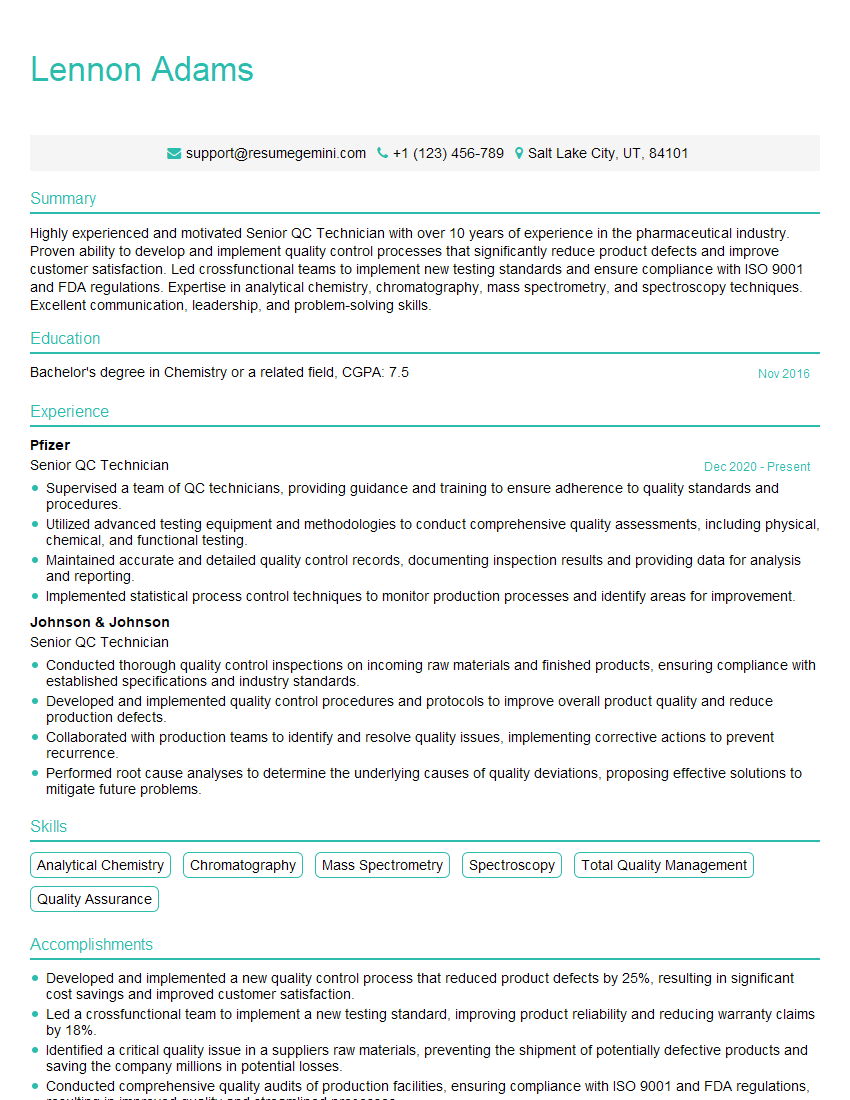

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Senior QC Technician

1. Describe the key responsibilities and duties of a Senior QC Technician?

As a Senior QC Technician, my key responsibilities would involve:

- Establishing and implementing quality control procedures to ensure product quality meets industry standards.

- Conducting rigorous inspections and testing of products at various stages of production.

- Analyzing and interpreting test results to identify potential quality issues and recommend corrective actions.

- Documenting and maintaining quality control records to track and monitor product performance.

- Collaborating with production teams to identify and resolve quality issues, ensuring production efficiency.

- Providing technical guidance and support to junior QC technicians and production staff.

- Staying updated on industry best practices and regulations related to quality control.

2. How do you ensure that products meet the required quality standards?

Quality Control Processes

- Developing and implementing comprehensive quality control plans that outline the inspection and testing criteria.

- Establishing quality thresholds and acceptance limits based on industry regulations and customer specifications.

Testing and Inspection

- Conducting thorough inspections and tests using specialized equipment and techniques.

- Evaluating product performance, dimensions, materials, and workmanship against established standards.

Data Analysis and Reporting

- Analyzing test results to identify trends, patterns, and non-conformances.

- Preparing detailed quality control reports that summarize findings, highlight areas for improvement, and recommend corrective actions.

3. Can you describe the different types of quality control tests you have experience with?

Throughout my career, I have gained extensive experience in various quality control testing methods, including:

- Dimensional Inspection: Verifying product dimensions and tolerances using precision measuring tools.

- Functional Testing: Evaluating the functionality and performance of products under simulated operating conditions.

- Material Testing: Assessing the physical and chemical properties of materials used in products, such as strength, durability, and composition.

- Non-Destructive Testing (NDT): Utilizing techniques like ultrasonic and X-ray to identify defects without damaging the product.

- Statistical Process Control (SPC): Monitoring and analyzing production processes to identify and control variations that could impact quality.

4. What is your approach to identifying and resolving quality issues?

Problem Identification

- Analyzing quality control data, customer feedback, and inspection reports to identify potential issues.

- Inspecting products to confirm and isolate the source of the problem.

Root Cause Analysis

- Using problem-solving techniques such as the “5 Whys” or fishbone diagrams to identify the underlying causes of the issue.

- Reviewing production processes, materials, and equipment to pinpoint the source of the problem.

Corrective Action

- Developing and implementing corrective actions to address the identified root causes.

- Monitoring the effectiveness of corrective actions to ensure the issue is resolved.

Preventive Measures

- Proactively identifying and implementing measures to prevent the recurrence of similar issues.

- Updating quality control procedures and training staff on preventive measures.

5. How do you manage and prioritize multiple quality control projects?

- Using project management tools and techniques to organize and track projects.

- Prioritizing projects based on risk, impact, and customer requirements.

- Delegating tasks to team members and providing clear instructions.

- Communicating regularly with stakeholders to ensure alignment and timely project completion.

- Monitoring project progress and making adjustments as needed to stay on schedule and within budget.

6. What is your experience with quality management systems and certifications?

I am well-versed in various quality management systems and certifications, including:

- ISO 9001: Implemented and maintained ISO 9001 quality management systems in multiple organizations.

- AS9100: Ensured compliance with AS9100 standards for the aerospace industry.

- FDA GMP: Audited and monitored production processes for compliance with FDA Good Manufacturing Practices (GMP).

- Six Sigma: Utilized Six Sigma methodologies for process improvement and quality optimization.

7. How do you stay up-to-date on industry best practices and regulations related to quality control?

- Attending industry conferences, workshops, and training programs.

- Reading technical journals and publications.

- Participating in professional organizations and networking with other quality control professionals.

- Staying informed about regulatory changes and updates.

- Seeking certifications and professional development opportunities.

8. Can you describe a situation where you successfully resolved a complex quality issue?

- Problem: Excessive scrap rates on a critical component.

- Approach: Conducted a thorough investigation using SPC and dimensional analysis.

- Root Cause: Identified an issue with the calibration of a key manufacturing machine.

- Corrective Action: Recalibrated the machine and implemented new inspection procedures.

- Result: Scrap rates reduced significantly, resulting in substantial cost savings.

9. What are the ethical considerations in quality control?

- Integrity and Objectivity: Maintaining impartiality and avoiding conflicts of interest.

- Confidentiality: Protecting sensitive quality control information.

- Responsibility: Taking ownership of quality control decisions and actions.

- Transparency: Openly sharing quality control data and results with stakeholders.

- Continuous Improvement: Striving to improve quality control processes and systems.

10. What motivates you to excel as a Senior QC Technician?

- Passion for Quality: Deeply committed to ensuring product quality and safety.

- Problem-Solving: Excited by the challenge of identifying and resolving complex quality issues.

- Continuous Improvement: Driven to optimize quality control processes and drive operational excellence.

- Customer Satisfaction: Motivated by the knowledge that my efforts contribute to customer satisfaction and safety.

- Teamwork: Enjoy collaborating with colleagues and sharing knowledge to achieve common goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Senior QC Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Senior QC Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Senior QC Technicians are responsible for ensuring the quality of products and services meet the company’s standards. They play a vital role in maintaining the company’s reputation and customer satisfaction.

1. Quality Control

Senior QC Technicians are responsible for developing and implementing quality control procedures. They must be able to identify and correct defects in products and services. They must also be able to track and trend quality data to identify areas for improvement.

- Develop and implement quality control procedures.

- Conduct quality control inspections.

- Identify and correct defects.

- Track and trend quality data.

2. Quality Assurance

Senior QC Technicians are also responsible for quality assurance. They must review and approve product and service designs before they are released to production. They must also ensure that the manufacturing process is followed correctly and that the finished products meet the company’s standards.

- Review and approve product and service designs.

- Ensure that the manufacturing process is followed correctly.

- Inspect finished products to ensure they meet the company’s standards.

- Investigate customer complaints and resolve issues.

3. Training and Development

Senior QC Technicians are responsible for training and developing other QC Technicians. They must be able to effectively communicate quality control procedures and techniques to new employees. They must also be able to provide guidance and support to other QC Technicians.

- Train and develop other QC Technicians.

- Provide guidance and support to other QC Technicians.

- Stay up-to-date on the latest quality control techniques.

4. Regulatory Compliance

Senior QC Technicians are also responsible for ensuring that the company complies with all applicable quality control regulations. They must be familiar with the quality control regulations that apply to the company’s products and services.

- Ensure that the company complies with all applicable quality control regulations.

- Stay up-to-date on the latest quality control regulations.

Interview Tips

To ace the interview for a Senior QC Technician position, it is important to be prepared. Here are a few tips to help you prepare:

1. Research the Company

Before the interview, take some time to research the company. This will help you understand the company’s culture, values, and products/services. You should also research the specific job you are applying for. This will help you understand the company’s expectations for the position.

2. Practice Your Answers

Once you have researched the company, it is important to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview. Some common interview questions for Senior QC Technician positions include:

- “Tell me about your experience in quality control.”

- “What are your strengths and weaknesses as a QC Technician?”

- “Why are you interested in working for our company?”

- “What are your career goals?”

3. Dress Professionally

It is important to dress professionally for the interview. This will show the interviewer that you are serious about the position. You should also arrive on time for the interview and be prepared to speak about your experience and qualifications.

4. Be Enthusiastic

Be enthusiastic about the position and the company during the interview. This will show the interviewer that you are excited about the opportunity to work for the company. You should also be prepared to talk about your ideas and how you can contribute to the company.

5. Ask Questions

At the end of the interview, be sure to ask the interviewer questions. This will show the interviewer that you are interested in the position and the company. You should also ask questions about the company’s culture, values, and products/services.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Senior QC Technician interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.