Are you gearing up for an interview for a Separating and Filtering Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Separating and Filtering Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

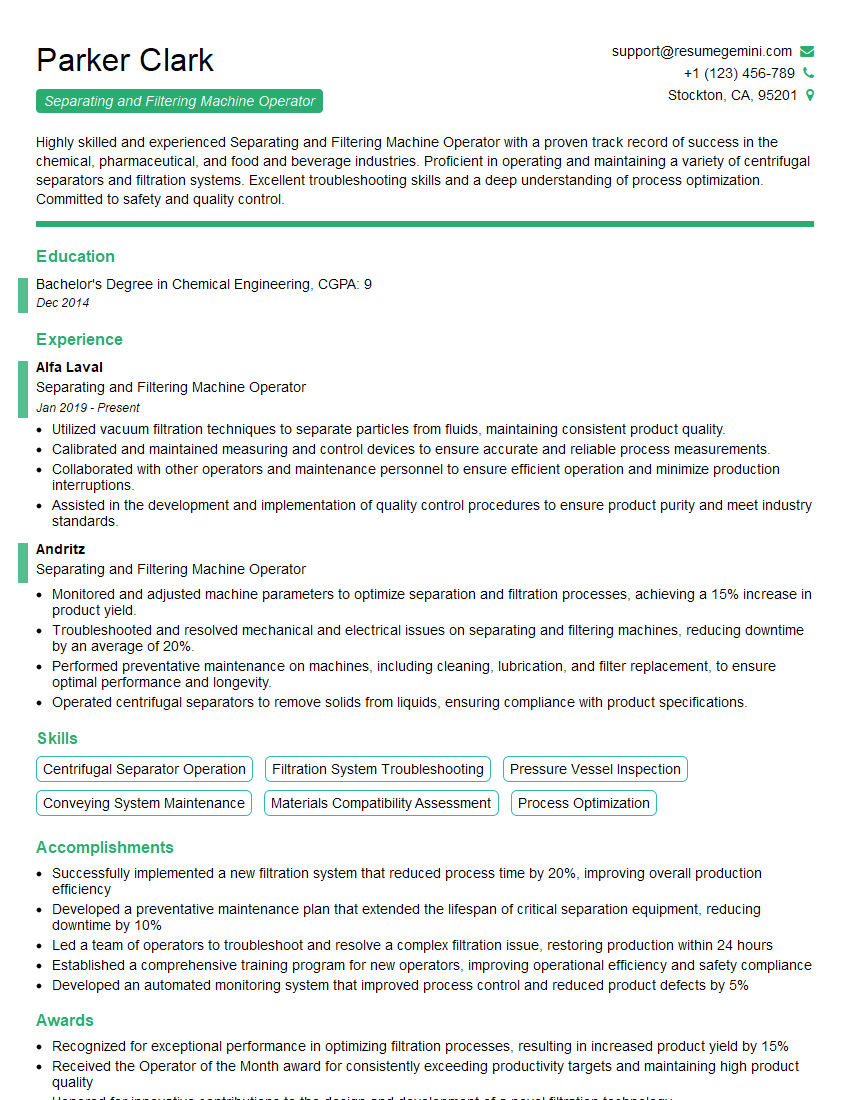

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Separating and Filtering Machine Operator

1. Describe the different types of separating and filtering equipment that you have experience operating?

I have experience operating a variety of separating and filtering equipment, including:

- Centrifuges

- Filters (e.g., bag filters, cartridge filters, plate-and-frame filters, and belt filters)

- Screens (e.g., vibrating screens, gravity screens, and trommels)

- Hydrocyclones

- Flotation cells

2. What are the key factors to consider when selecting the appropriate separating or filtering equipment for a particular application?

Process requirements

- Desired separation or filtration efficiency

- Feed characteristics (e.g., particle size, density, and viscosity)

- Capacity requirements

Equipment capabilities

- Separation or filtration mechanism

- Efficiency

- Capacity

- Maintenance requirements

Economic considerations

- Capital cost

- Operating cost

- Maintenance cost

3. What are some of the common problems that can occur with separating and filtering equipment, and how do you troubleshoot them?

Some common problems that can occur with separating and filtering equipment include:

- Blockage or clogging

- Reduced efficiency

- Mechanical failure

To troubleshoot these problems, I would typically:

- Check for any blockages or clogs in the equipment.

- Inspect the equipment for any signs of wear or damage.

- Check the operating conditions of the equipment to ensure that they are within the specified range.

- Refer to the manufacturer’s instructions for troubleshooting and maintenance procedures.

4. What are the safety precautions that need to be taken when operating separating and filtering equipment?

The following are some of the safety precautions that need to be taken when operating separating and filtering equipment:

- Wear appropriate personal protective equipment (e.g., gloves, safety glasses, and hearing protection).

- Be aware of the location of all emergency stops and shut-off switches.

- Do not operate equipment that is not properly maintained or has any safety hazards.

- Follow all manufacturer’s instructions for safe operation.

- Do not attempt to repair or maintain equipment unless you are qualified to do so.

5. Have you ever had to work as part of a team to operate and maintain separating and filtering equipment?

Yes, I have worked as part of a team to operate and maintain separating and filtering equipment on several occasions.

- In one instance, I was part of a team that was responsible for operating and maintaining a large centrifuge used to separate solids from liquids.

- My responsibilities included monitoring the equipment, making adjustments to the operating parameters, and performing routine maintenance.

- I worked closely with other team members to ensure that the equipment was operating efficiently and safely.

I find that working as part of a team can be very rewarding and allows me to learn from others and share my knowledge.

6. What is your understanding of the principles of separation and filtration?

The principles of separation and filtration are based on the physical properties of the materials being processed. In separation, the objetivo is to separate two or more materials based on their differences in size, density, or other physical properties.

- In filtration, the objetivo is to remove particles from a fluid by passing it through a filter medium that traps the particles.

The choice of separation or filtration method depends on the specific requirements of the application.

7. How do you ensure that the equipment is operating at optimal efficiency?

- By following the manufacturer’s recommended maintenance schedule.

- By monitoring the equipment’s performance and making adjustments as needed.

- By using the appropriate chemicals and additives.

- By training operators on proper operation and maintenance procedures.

8. How do you handle unexpected equipment failures?

- By identifying the problem and taking corrective action.

- By contacting the manufacturer or a qualified technician for assistance.

- By documenting the problem and the corrective action taken.

9. What are your goals for this role?

- To use my skills and experience to help the company achieve its goals.

- To learn new things and develop my skills.

- To contribute to the team and make a positive impact on the company.

10. Why are you interested in working for our company?

- Because I am impressed by the company’s commitment to quality and innovation.

- Because I believe that my skills and experience would be a valuable asset to the company.

- Because I am eager to learn and grow in this role.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Separating and Filtering Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Separating and Filtering Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Separating and Filtering Machine Operator is responsible for the safe and efficient operation of separating and filtering machines that are used to separate solids from liquids, or to separate different liquids from each other. The key job responsibilities of a Separating and Filtering Machine Operator include:

1. Operating Separating and Filtering Machines

Separating and Filtering Machine Operators are responsible for operating a variety of machines, including centrifuges, filters, and screens. They must be able to adjust the machines to the correct settings for the materials being processed and ensure that the machines are running smoothly and efficiently.

- Loading and unloading materials into and out of the machines

- Adjusting the machines to the correct settings

- Monitoring the operation of the machines

- Cleaning and maintaining the machines

2. Ensuring Product Quality

Separating and Filtering Machine Operators are also responsible for ensuring that the product being processed meets the desired quality specifications. They must be able to identify and correct any problems that may occur during the separation or filtration process.

- Inspecting the product before and after processing

- Identifying and correcting any problems that may occur during processing

- Maintaining records of the processing operation

3. Maintaining a Safe and Clean Work Environment

Separating and Filtering Machine Operators must be able to maintain a safe and clean work environment. They must be familiar with the safety procedures for operating the machines and must be able to identify and correct any potential hazards.

- Following safety procedures

- Identifying and correcting any potential hazards

- Keeping the work area clean and organized

4. Other Responsibilities

In addition to the key job responsibilities listed above, Separating and Filtering Machine Operators may also be responsible for performing the following tasks:

- Packaging and shipping the finished product

- Labeling and storing the finished product

- Assisting with other tasks as needed

Interview Tips

To prepare for an interview for a Separating and Filtering Machine Operator position, you should:

1. Research the company and the position

Take the time to learn about the company and the specific position you are applying for. This will help you to understand the company’s culture and the expectations for the role.

2. Practice answering common interview questions

There are a number of common interview questions that you may be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

3. Be prepared to discuss your experience and skills

The interviewer will want to know about your experience and skills as a Separating and Filtering Machine Operator. Be prepared to discuss your experience in detail, including the types of machines you have operated and the products you have processed.

4. Demonstrate your safety knowledge

Safety is a top priority in any manufacturing environment. Be prepared to demonstrate your knowledge of safety procedures and your ability to identify and correct potential hazards.

5. Be enthusiastic and positive

Interviewers are looking for candidates who are enthusiastic and positive about their work. Be sure to convey your passion for the field and your desire to join the team.

Next Step:

Now that you’re armed with the knowledge of Separating and Filtering Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Separating and Filtering Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini