Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Separating Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

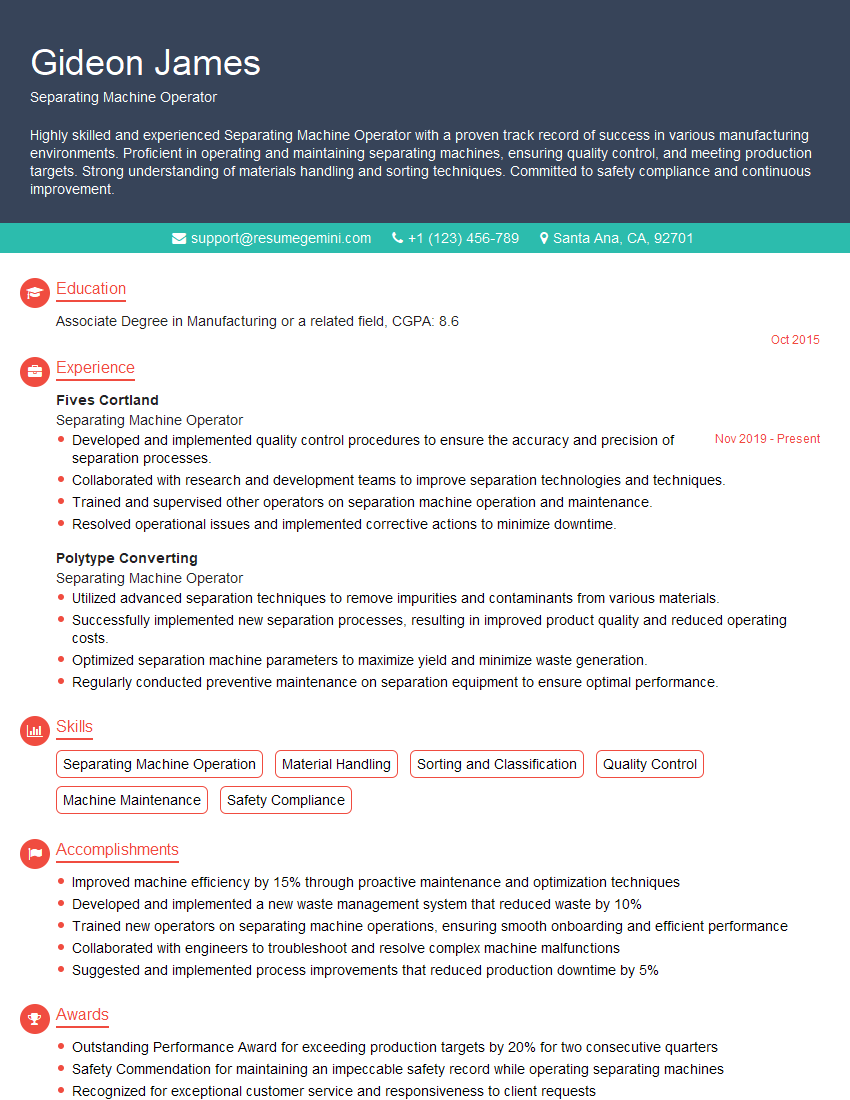

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Separating Machine Operator

1. What are the key responsibilities of a Separating Machine Operator?

- Operate and maintain separating machines to separate materials based on density, size, or other characteristics.

- Ensure that the machines are calibrated and running efficiently.

- Monitor the separation process and make adjustments as needed.

- Clean and maintain the machines and work area.

- Follow safety procedures and regulations.

2. What are the different types of separating machines?

types of separating machines

- Gravity Separators

- Magnetic Separators

- Electrostatic Separators

- Flotation Separators

- Centrifugal Separators

working of the each separating machine

- Gravity Separators: These machines use the principle of gravity to separate materials based on their density. The heavier particles will sink to the bottom of the machine, while the lighter particles will float to the top.

- Magnetic Separators: These machines use magnets to separate magnetic materials from non-magnetic materials. The magnetic materials will be attracted to the magnets, while the non-magnetic materials will not.

- Electrostatic Separators: These machines use electrostatic charges to separate materials based on their electrical conductivity. The electrically conductive materials will be attracted to one electrode, while the non-conductive materials will be attracted to the other electrode.

- Flotation Separators: These machines use air bubbles to separate materials based on their hydrophobicity. The hydrophobic materials will attach to the air bubbles and float to the surface, while the hydrophilic materials will sink to the bottom.

- Centrifugal Separators: These machines use centrifugal force to separate materials based on their density. The heavier particles will be forced to the outside of the machine, while the lighter particles will be forced to the inside.

3. What are the factors that affect the efficiency of a separating machine?

- The type of material being separated

- The size of the material being separated

- The density of the material being separated

- The moisture content of the material being separated

- The temperature of the material being separated

- The speed of the machine

- The calibration of the machine

- The maintenance of the machine

4. What are the safety precautions that should be taken when operating a separating machine?

- Wear appropriate safety gear, such as gloves, eye protection, and a dust mask.

- Keep the work area clean and free of debris.

- Do not operate the machine if it is not properly calibrated.

- Do not attempt to clean or repair the machine while it is running.

- Follow all manufacturer’s instructions.

5. What are the troubleshooting tips for a separating machine?

- If the machine is not separating the materials properly, check the calibration.

- If the machine is not running smoothly, check the bearings and belts.

- If the machine is making noise, check for loose parts.

- If the machine is leaking, check for leaks in the hoses or pipes.

- If the machine is not starting, check the power supply.

6. What are the maintenance tips for a separating machine?

- Clean the machine regularly.

- Lubricate the bearings and belts regularly.

- Check the hoses and pipes for leaks regularly.

- Calibrate the machine regularly.

- Follow all manufacturer’s instructions.

7. What are the different types of conveyors used in a separating plant?

- Belt conveyors

- Screw conveyors

- Chain conveyors

- Pneumatic conveyors

- Hydraulic conveyors

8. What are the different types of screens used in a separating plant?

- Flat screens

- Rotating screens

- Vibrating screens

- Centrifugal screens

9. What are the different types of crushers used in a separating plant?

- Jaw crushers

- Gyratory crushers

- Cone crushers

- Hammer crushers

- Roll crushers

10. What are the different types of feeders used in a separating plant?

- Vibratory feeders

- Apron feeders

- Belt feeders

- Screw feeders

- Reciprocating feeders

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Separating Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Separating Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Separating Machine Operators are responsible for operating and maintaining separating machines that remove impurities from various materials. They play a critical role in ensuring the quality and purity of products in various industries.

1. Machine Operation and Maintenance

Operate separating machines according to established procedures to separate materials based on properties such as size, density, or magnetic susceptibility.

- Monitor machine performance, adjust settings, and troubleshoot malfunctions to maximize efficiency and minimize downtime.

- Perform routine maintenance tasks, such as cleaning, lubrication, and minor repairs, to ensure equipment reliability.

2. Material Handling

Load and unload materials into and out of the separating machine, ensuring proper handling techniques to prevent damage or contamination.

- Inspect materials before and after separation to ensure quality standards are met.

- Dispose of separated impurities and waste according to established procedures.

3. Quality Control

Monitor the separation process to ensure that the desired level of separation is achieved.

- Inspect separated materials to identify and remove any remaining impurities.

- Maintain records of separation performance and identify areas for improvement.

4. Safety and Compliance

Adhere to all safety regulations and procedures while operating the separating machine and handling materials.

- Wear appropriate personal protective equipment (PPE) to minimize exposure to hazards.

- Follow established protocols for handling hazardous materials.

Interview Tips

Preparing thoroughly for a Separating Machine Operator interview is crucial to showcase your skills and increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s industry, products, and culture. Research the specific role you are applying for to understand its responsibilities and expectations.

- Visit the company website and review their mission statement, values, and recent news.

- Check industry publications and online forums to gather insights about the company and the position.

2. Practice Your Answers

Prepare for common interview questions related to your experience, skills, and qualifications. Practice answering these questions clearly and concisely, highlighting your relevant abilities.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Ask a friend or family member to conduct a mock interview to provide feedback and help you improve your delivery.

3. Highlight Your Skills and Experience

Emphasize your technical skills in operating and maintaining separating machines. Provide examples of your ability to troubleshoot problems and optimize machine performance.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- If you have experience in a similar industry or role, highlight how your transferable skills can benefit the company.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare questions that demonstrate your understanding of the role and the company, and that highlight your enthusiasm for the opportunity.

- Ask about the company’s growth plans, industry trends, or specific challenges related to the position.

- Inquire about opportunities for professional development and advancement within the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Separating Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.