Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Separator Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

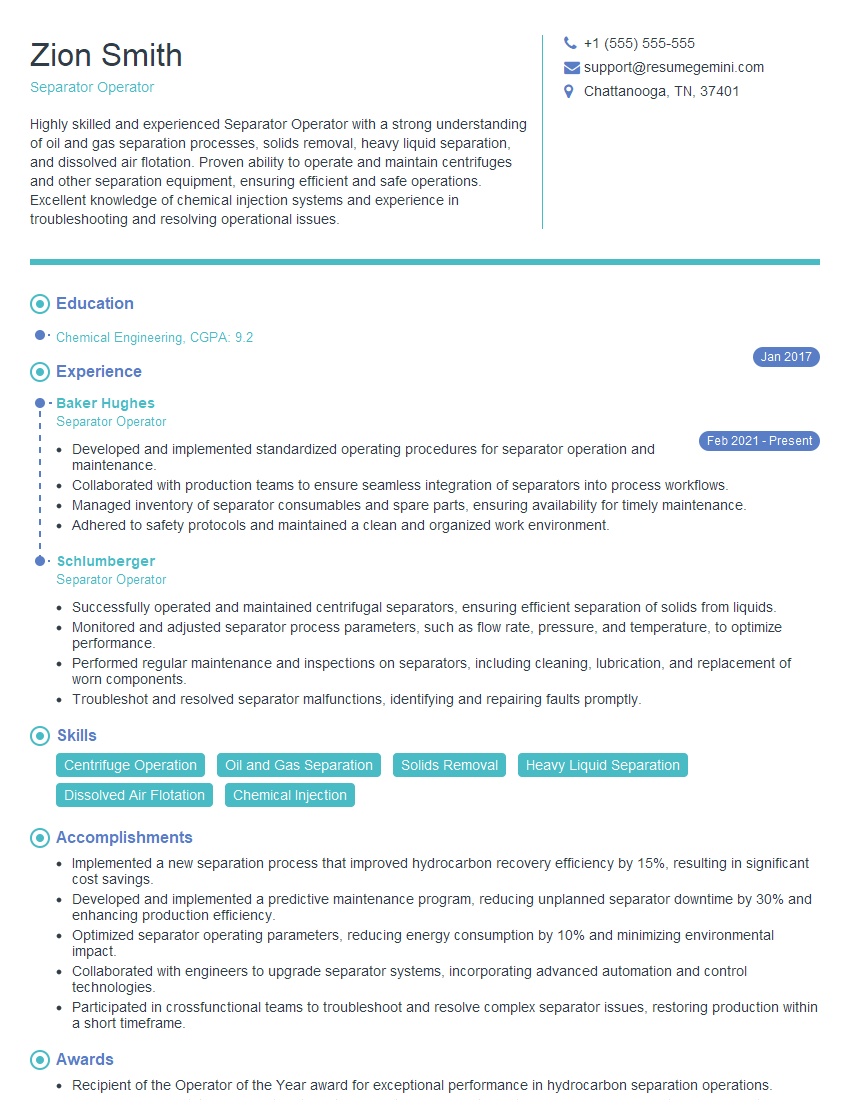

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Separator Operator

1. Describe the process of centrifugal separation?

Centrifugal separation is a mechanical process that uses centrifugal force to separate particles of different densities. It is commonly used to separate solids from liquids, or liquids from liquids, based on their different sedimentation rates.

- The mixture is placed in a centrifuge, which spins at high speed.

- The centrifugal force causes the particles to move outward from the center of the centrifuge, with the denser particles moving further out than the less dense particles.

- The particles eventually form layers, with the densest particles at the bottom and the least dense particles at the top.

- The layers can then be separated and collected.

2. What are the different types of separators used in the oil and gas industry?

Separators for Gas-Liquid Separation

- Gravity Separators

- Centrifugal Separators

- Coalescers

Separators for Liquid-Liquid Separation

- Gravity Separators

- Centrifugal Separators

- Electrostatic Separators

Separators for Solid-Liquid Separation

- Gravity Settlers

- Centrifugal Separators

- Hydrocyclones

3. What are the factors that affect the efficiency of a separator?

The efficiency of a separator is affected by a number of factors, including:

- The density difference between the particles being separated

- The flow rate of the mixture

- The rotational speed of the centrifuge

- The size and shape of the particles

- The temperature of the mixture

4. What are the common problems that can occur with separators?

Common problems that can occur with separators include:

- Clogging

- Fouling

- Erosion

- Corrosion

- Mechanical failure

5. How do you troubleshoot and maintain a separator?

Troubleshooting and maintaining a separator involves the following steps:

- Identifying the problem

- Determining the cause of the problem

- Taking corrective action

- Preventing the problem from recurring

6. What safety precautions should be taken when working with separators?

When working with separators, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a hard hat.

- Be aware of the potential hazards associated with separators, such as rotating equipment, high pressure, and hazardous chemicals.

- Follow all safety procedures and guidelines.

- Never attempt to operate a separator without proper training.

7. What are the different types of control systems used in separators?

The different types of control systems used in separators include:

- Manual control

- Automatic control

- Computer control

8. What are the advantages and disadvantages of using a centrifugal separator?

Advantages

- High efficiency

- Compact size

- Low maintenance

Disadvantages

- High cost

- Not suitable for all applications

- Can be sensitive to changes in operating conditions

9. What are the different types of materials used in the construction of separators?

The different types of materials used in the construction of separators include:

- Stainless steel

- Carbon steel

- Aluminum

- Titanium

- Plastics

10. What are the latest trends in separator technology?

The latest trends in separator technology include:

- The development of more efficient and compact separators

- The use of new materials and designs to improve performance and reliability

- The integration of advanced control systems to improve automation and efficiency

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Separator Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Separator Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Separator Operator is responsible for operating and maintaining separation equipment in industrial settings. Their primary duties involve ensuring efficient and safe separation of various materials, such as liquids, solids, and gases.

1. Equipment Operation

Operate and monitor separators, such as centrifuges, filters, and decanters, to separate materials based on their physical properties

- Adjust and optimize separator settings to achieve desired separation results

- Monitor separator performance and troubleshoot any operational issues

2. Material Handling

Load, unload, and transfer materials to and from separators

- Inspect materials for quality and ensure proper handling

- Follow established safety protocols for handling hazardous materials

3. Equipment Maintenance

Perform routine maintenance and cleaning of separators to ensure optimal functionality

- Identify and replace worn or damaged parts

- Lubricate and adjust separator components

4. Quality Control

Monitor and test separated materials to ensure they meet specifications

- Collect and analyze samples to verify material purity and quality

- Maintain documentation and records of separation processes

Interview Tips

To ace an interview for a Separator Operator position, it’s crucial to demonstrate your technical skills, attention to detail, and ability to work in a fast-paced industrial environment.

1. Research the Company and Industry

Familiarize yourself with the organization’s background, products, and market position.

- Research industry trends and best practices related to separation technologies.

2. Highlight Your Experience and Skills

Emphasize your hands-on experience in operating and maintaining separation equipment.

- Quantify your accomplishments, providing specific examples of successful separation processes you’ve managed.

- Showcase your knowledge of different separation techniques and equipment.

3. Prepare for Technical Questions

Anticipate questions about your understanding of separation principles, troubleshooting abilities, and safety protocols.

- Review basic concepts of fluid dynamics, filtration, and centrifugation.

- Practice answering questions on how to handle common operational issues with separators.

4. Showcase Your Teamwork and Communication Skills

Separator Operators often work in production teams and need to communicate effectively.

- Describe your experience collaborating with colleagues and supervisors.

- Emphasize your ability to work independently and as part of a team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Separator Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!