Are you gearing up for an interview for a Set Up Inspector position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Set Up Inspector and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

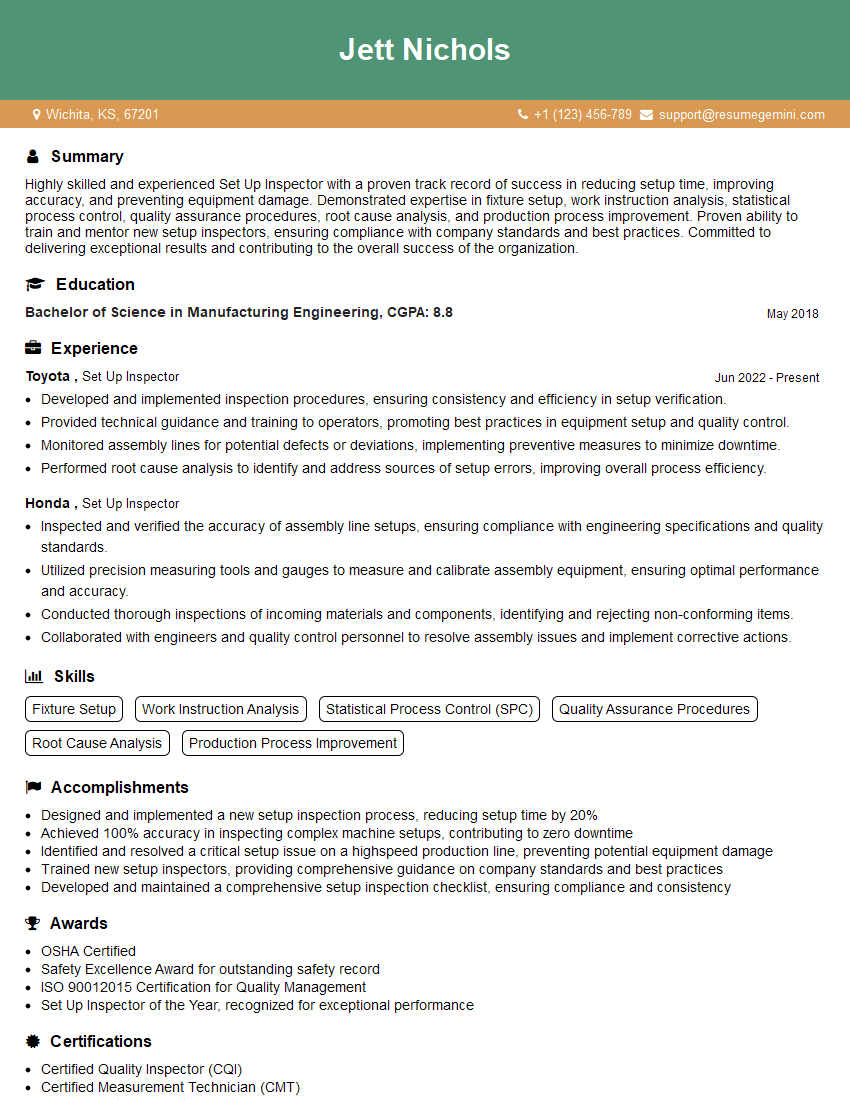

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Set Up Inspector

1. What are the key responsibilities of a Setup Inspector in a manufacturing environment?

As a Setup Inspector, my primary responsibilities would be to:

- Inspect and verify the proper setup of production equipment, ensuring compliance with established standards and specifications.

- Identify and address any deviations or discrepancies in equipment setup, initiating corrective actions as necessary.

2. What techniques do you employ to ensure the accuracy and efficiency of your inspections?

Precision Measuring Tools:

- Utilize precision measuring tools such as micrometers, calipers, and gauges to verify dimensions and tolerances.

- Ensure tools are calibrated and maintained regularly for optimal accuracy.

Inspection Checklists:

- Use detailed inspection checklists to systematically assess equipment functionality, settings, and any potential risks.

- Document findings and observations accurately, providing clear and concise reports.

3. How do you prioritize inspections and allocate your time effectively?

I prioritize inspections based on the following criteria:

- Critical equipment that can impact production efficiency and safety.

- Equipment that has undergone significant changes or maintenance.

- Equipment with a history of recurring issues or non-conformities.

To allocate my time effectively, I use a structured inspection schedule and leverage technology to streamline processes.

4. What quality standards are you familiar with and how do you apply them in your inspections?

I am well-versed in industry-recognized quality standards, including:

- ISO 9001:2015 Quality Management Systems

- ASME B46.1 Surface Texture (Surface Roughness, Waviness, and Lay)

- ANSI/ASQ Z1.4 Sampling Procedures and Tables for Inspection by Attributes

I apply these standards by adhering to their specifications and requirements during inspections, ensuring that products and processes meet the desired quality levels.

5. How do you handle discrepancies or non-conformities identified during inspections?

Upon identifying discrepancies or non-conformities, I take the following steps:

- Document the issue clearly, capturing details such as the nature of the non-conformity, its location, and any potential impact.

- Inform the relevant personnel promptly, including supervisors, engineers, and maintenance technicians.

- Initiate corrective actions by working collaboratively with the team to determine the root cause and implement appropriate solutions.

6. What software programs or tools are you proficient in using for inspection and reporting purposes?

- Inspection management software (e.g., Q-Pulse, iAuditor, Inspecto)

- Data analysis and reporting tools (e.g., Excel, Power BI, Tableau)

- Computer-aided design (CAD) software (e.g., AutoCAD, SolidWorks)

7. How do you stay up-to-date with advancements in inspection techniques and technologies?

- Attend industry conferences and seminars.

- Read technical publications and journals.

- Engage in online forums and discussions.

- Collaborate with colleagues and experts in the field.

8. What is your approach to working effectively as part of a team?

I believe in the power of teamwork and contribute effectively by:

- Communicating clearly and openly, sharing information and updates.

- Collaborating with others to solve problems and find solutions.

- Supporting my team members and providing assistance when needed.

9. How do you handle situations where there are production pressures and deadlines to meet while maintaining quality standards?

I prioritize tasks and allocate my time effectively to meet deadlines while ensuring quality.

- Focus on critical inspections that have the greatest impact on product quality.

- Use technology and automation to streamline inspections and improve efficiency.

- Communicate regularly with the production team to understand their needs and constraints.

10. Describe a challenging inspection scenario you encountered and how you overcame it.

One challenging scenario I faced was inspecting a complex assembly with multiple components and tight tolerances.

- I used a combination of precision measuring tools and CAD software to verify dimensions and clearances.

- I identified a discrepancy in one of the components and worked with the supplier to resolve the issue.

- Through thorough inspections and collaboration, I ensured that the assembly met the required specifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Set Up Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Set Up Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Set Up Inspector is responsible for ensuring that all equipment and materials are properly set up and calibrated before production begins. The Set Up Inspector must have a strong understanding of the production process and the equipment used in the process. This position requires the ability to work independently and as part of a team.

1. Equipment set-up and calibration

The Set Up Inspector is responsible for setting up and calibrating all equipment used in the production process. This includes making sure that all equipment is properly leveled, aligned, and tightened. The Set Up Inspector must also calibrate all measuring and testing equipment to ensure that it is accurate.

- Inspect and verify the accuracy of all measuring and testing equipment

- Set up and calibrate all production equipment according to specifications

- Troubleshoot and resolve any equipment malfunctions

2. Material inspection

The Set Up Inspector is responsible for inspecting all materials used in the production process. This includes checking for defects, damage, and contamination. The Set Up Inspector must also verify that all materials meet the specifications for the product being produced.

- Inspect all incoming materials for defects, damage, and contamination

- Verify that all materials meet the specifications for the product being produced

- Reject any materials that do not meet specifications

3. Production monitoring

The Set Up Inspector is responsible for monitoring the production process to ensure that it is running smoothly. The Set Up Inspector must identify any potential problems and take corrective action to prevent them from occurring. The Set Up Inspector must also ensure that all products meet the specifications for the product being produced.

- Monitor the production process to ensure that it is running smoothly

- Identify any potential problems and take corrective action to prevent them from occurring

- Ensure that all products meet the specifications for the product being produced

4. Quality control

The Set Up Inspector is responsible for ensuring that all products meet the quality standards for the product being produced. The Set Up Inspector must inspect all products for defects, damage, and contamination. The Set Up Inspector must also ensure that all products are properly packaged and labeled.

- Inspect all products for defects, damage, and contamination

- Ensure that all products meet the quality standards for the product being produced

- Properly package and label all products

Interview Tips

Here are some tips that candidates can use to help them ace their interview for a Set Up Inspector position:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you understand the specific responsibilities of the Set Up Inspector position.

- Visit the company’s website

- Read about the company in industry publications

- Talk to people who work at the company

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions

- Prepare specific examples of your skills and experience

- Practice your answers with a friend or family member

3. Be prepared to talk about your experience in setting up and calibrating equipment

The interviewer will want to know about your experience in setting up and calibrating equipment. Be prepared to discuss your experience in detail, including the types of equipment you have worked with and the calibration procedures you have used.

- Highlight your experience in setting up and calibrating production equipment

- Describe the calibration procedures you have used

- Provide examples of how you have used your skills to improve efficiency or quality

4. Be enthusiastic and professional

The interviewer will be looking for someone who is enthusiastic and passionate about their work. Be sure to convey your enthusiasm for the Set Up Inspector position and your desire to work for the company. Also, be sure to be professional and respectful throughout the interview.

- Dress professionally

- Be on time for your interview

- Be polite and respectful to the interviewer

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Set Up Inspector interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.