Are you gearing up for a career in Set-Up Person? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Set-Up Person and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

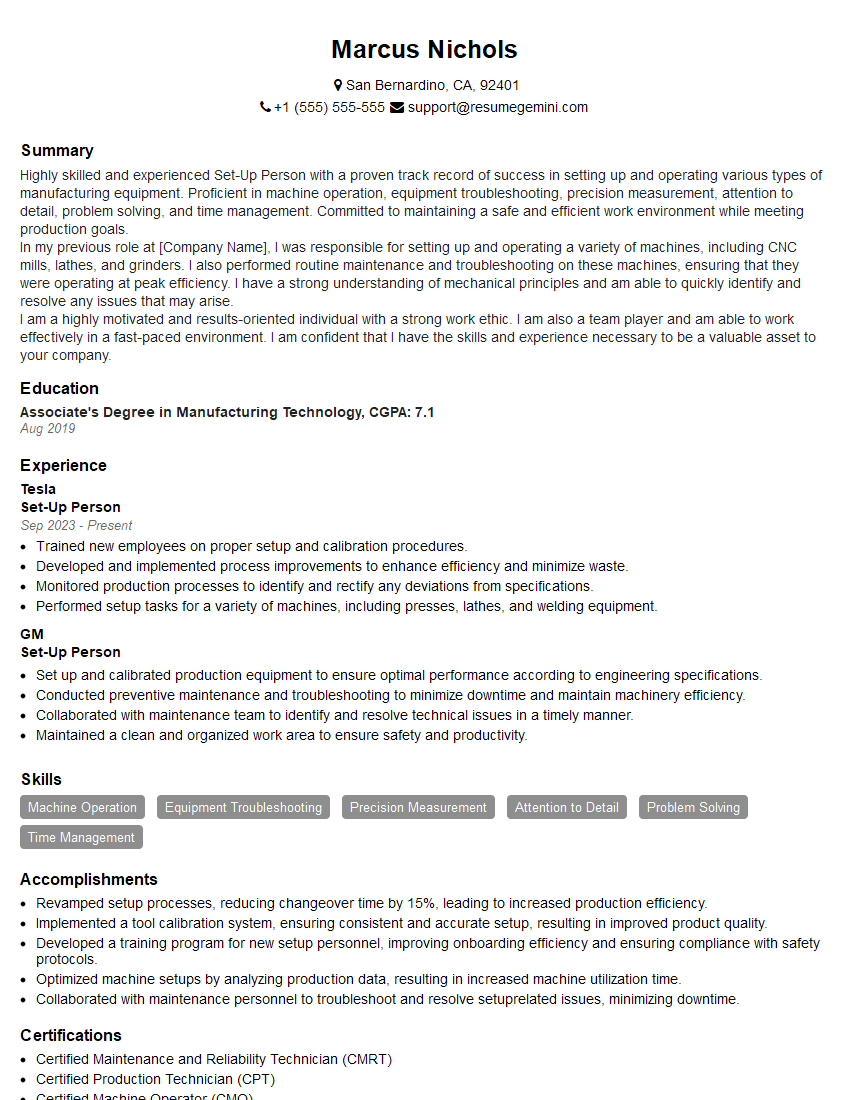

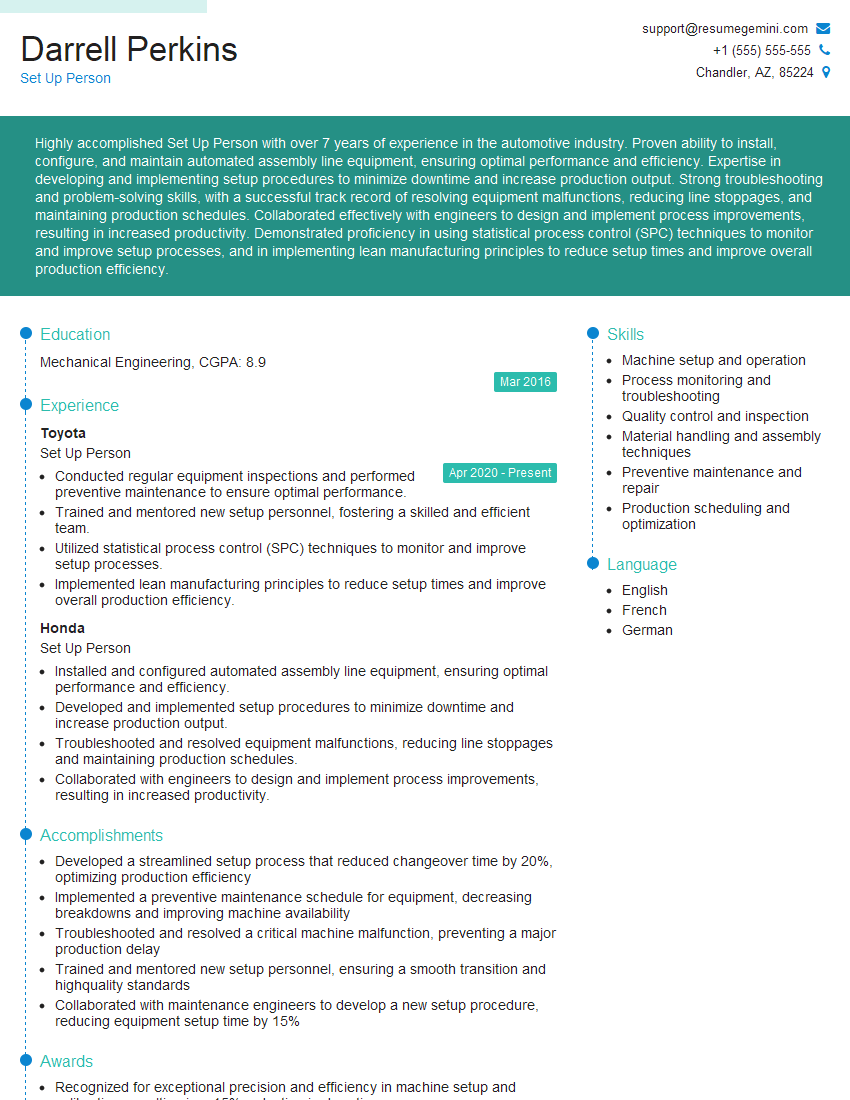

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Set-Up Person

1. How do you ensure that the equipment you set up is calibrated and meets industry standards?

To ensure the equipment I set up is calibrated and meets industry standards, I follow a rigorous process:

- Calibration Checks: I perform regular calibration checks using certified instruments to verify the accuracy and reliability of the equipment.

- Manufacturer’s Recommendations: I adhere to the manufacturer’s guidelines and specifications for calibration intervals and procedures.

- Documentation: I maintain detailed records of all calibration activities, including dates, results, and any adjustments made.

- Industry Regulations: I am familiar with industry regulations and standards for equipment calibration and ensure compliance.

2. Describe the procedures you follow to safely and efficiently set up and operate machinery.

Safety First: I prioritize safety by:

Wearing Appropriate PPE

- Safety glasses, gloves, earplugs, and a hard hat when necessary.

Proper Lockout/Tagout Procedures

- Ensuring machinery is isolated and de-energized before performing any work.

Electrical Safety

- Inspecting electrical connections for damage or loose wires.

Efficient Operation: I follow established setup procedures, including:

Equipment Familiarization

- Reviewing equipment manuals and understanding its functionality.

Proper Alignment and Tightening

- Using precise measurements and tools for accurate alignment.

Testing and Troubleshooting

- Performing test runs and addressing any issues before full operation.

3. How do you troubleshoot and resolve equipment malfunctions efficiently?

I follow a systematic troubleshooting approach when faced with equipment malfunctions:

- Observe and Identify: Note the symptoms, error messages, or unusual behaviors.

- Check Basics: Verify power supply, loose connections, or simple configuration errors.

- Refer to Documentation: Consult equipment manuals and troubleshooting guides for specific solutions.

- Logical Troubleshooting: Use a logical sequence to isolate the problem, considering potential causes and effects.

- Test and Verify: Implement corrective measures and test the equipment to ensure the issue is resolved.

4. Describe your experience with using precision measuring instruments and tools.

I am proficient in using various precision measuring instruments and tools, including:

- Calipers and Micrometers: Measuring dimensions with high accuracy.

- Dial Indicators: Detecting minute deviations and clearances.

- Levels and Squares: Ensuring equipment is level and aligned.

- Torques Wrenches: Applying precise torque to bolts and fittings.

- Digital Multimeters: Testing electrical circuits and components.

5. How do you prioritize and manage multiple work orders efficiently?

I prioritize and manage multiple work orders by:

- Establish Priorities: Assign urgency levels to work orders based on criticality and potential impact.

- Scheduling and Planning: Create a realistic work schedule, considering equipment availability and resource allocation.

- Effective Communication: Coordinate with colleagues and supervisors to ensure timely completion of tasks.

- Time Management: Utilize task lists, reminders, and time-tracking tools to stay organized and efficient.

- Continuous Improvement: Regularly review processes and identify areas for optimization.

6. Describe your experience with working in a team environment. How do you contribute to the team’s success?

I am an effective team player with experience working in collaborative environments:

- Communication and Collaboration: Actively participate in team discussions, share knowledge, and provide support to colleagues.

- Shared Goals: Align my individual efforts with the team’s goals and contribute to collective outcomes.

- Problem Solving: Bring different perspectives and ideas to problem-solving discussions and work together to find solutions.

- Mutual Support: Offer assistance and support to team members when needed and recognize their contributions.

- Respect and Understanding: Value diversity, respect different viewpoints, and maintain a positive and respectful work environment.

7. How do you stay updated with industry best practices and technological advancements relevant to your role?

I am committed to continuous learning and staying updated with industry best practices and technological advancements:

- Attend Industry Events: Participate in conferences, workshops, and seminars to gain insights from experts.

- Read Industry Publications: Subscribe to industry magazines, journals, and online forums to stay informed about emerging trends.

- Online Learning: Take advantage of online courses, webinars, and certifications to enhance my skills and knowledge.

- Network with Professionals: Connect with other industry professionals to share ideas and learn from their experiences.

- Internal Training: Actively seek out and participate in training opportunities provided by the company.

8. How do you ensure that the equipment you set up meets safety standards and regulations?

Ensuring equipment meets safety standards and regulations is paramount:

- OSHA Compliance: Familiarize myself with OSHA regulations and incorporate them into setup procedures.

- Manufacturer’s Specifications: Follow manufacturer’s guidelines for safe setup and operation of equipment.

- Risk Assessments: Conduct risk assessments to identify potential hazards and implement appropriate safety measures.

- Regular Inspections: Perform regular safety inspections to check for any defects or non-compliance issues.

- Employee Training: Train operators on proper equipment setup and safety protocols.

9. Describe your methods for training operators on the use of equipment.

My approach to training operators includes:

- Hands-on Training: Provide practical demonstrations and supervised practice on the equipment.

- Written Instructions: Develop clear and comprehensive operating manuals for reference.

- Verbal Explanations: Explain the equipment’s functionality, safety features, and proper operating procedures.

- Skill Assessments: Conduct assessments to evaluate operators’ understanding and proficiency.

- Ongoing Support: Offer ongoing support and guidance to operators as needed.

10. How do you handle situations where there is a discrepancy between the specifications and the actual equipment?

When there is a discrepancy between specifications and actual equipment:

- Verify Specifications: Recheck the specifications to ensure accuracy and avoid misunderstandings.

- Contact Manufacturer: Consult with the manufacturer to clarify any ambiguities or resolve discrepancies.

- Document Discrepancy: Record the discrepancy and communicate it to relevant parties, including the engineering team.

- Adjust Setup: If possible, adjust the setup to match the specifications or determine an alternative solution that meets safety and performance requirements.

- Prioritize Safety: Always prioritize operator safety and equipment integrity, ensuring any adjustments do not compromise these factors.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Set-Up Person.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Set-Up Person‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Set-Up Person plays a vital role in ensuring the smooth operation of a manufacturing or production process. Their key job responsibilities include:

1. Equipment Setup and Maintenance

Installing, configuring, and maintaining production equipment to meet production specifications.

- Reading and interpreting technical manuals

- Conducting preventive maintenance and repairs

2. Material Handling

Loading and unloading materials, components, and finished products.

- Operating forklifts and other material handling equipment

- Ensuring proper storage and inventory control

3. Process Optimization

Identifying and implementing process improvements to increase efficiency and reduce downtime.

- Monitoring production processes and identifying potential bottlenecks

- Collaborating with engineers and supervisors to develop and implement solutions

4. Safety Compliance

Maintaining a safe work environment by following established safety protocols.

- Wearing appropriate personal protective equipment

- Operating equipment in accordance with safety regulations

Interview Tips

Preparing thoroughly for a Set-Up Person interview is crucial to ace the assessment. Here are some tips to help you stand out:

1. Research the Company and Role

Familiarize yourself with the company’s products, services, and industry. Understand the specific responsibilities of the Set-Up Person.

- Visit the company’s website and social media pages

- Read industry publications and news

2. Highlight Relevant Experience

Emphasize your technical skills, including equipment setup, maintenance, and troubleshooting. Quantify your accomplishments whenever possible.

- Example: “Increased production efficiency by 15% through the implementation of a new equipment setup procedure.”

3. Demonstrate Problem-Solving Abilities

Provide examples of how you have solved problems in the past. Use the STAR method (Situation, Task, Action, Result) to present your experiences.

- Example: “Situation: Our production line experienced a sudden downtime. Task: I was assigned to diagnose and resolve the issue. Action: I conducted a thorough inspection of the equipment and identified a faulty component. Result: I replaced the component and restored the line to full operation within 30 minutes, minimizing production loss.”

4. Showcase Safety Consciousness

Emphasize your commitment to safety. Provide specific examples of how you have maintained a safe work environment.

- Example: “I always ensure that I am wearing proper personal protective equipment and that all equipment is operated in accordance with safety regulations. I also participate in regular safety training and drills.”

5. Ask Informed Questions

Asking thoughtful questions shows your engagement and interest in the role. Prepare questions about the company, the specific responsibilities, and opportunities for professional development.

- Example: “I am interested in learning more about the company’s commitment to sustainability. Could you please share some examples of how this is integrated into the manufacturing process?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Set-Up Person interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!