Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Set-Up Welder, Mig, Tig, and Stick Welding interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Set-Up Welder, Mig, Tig, and Stick Welding so you can tailor your answers to impress potential employers.

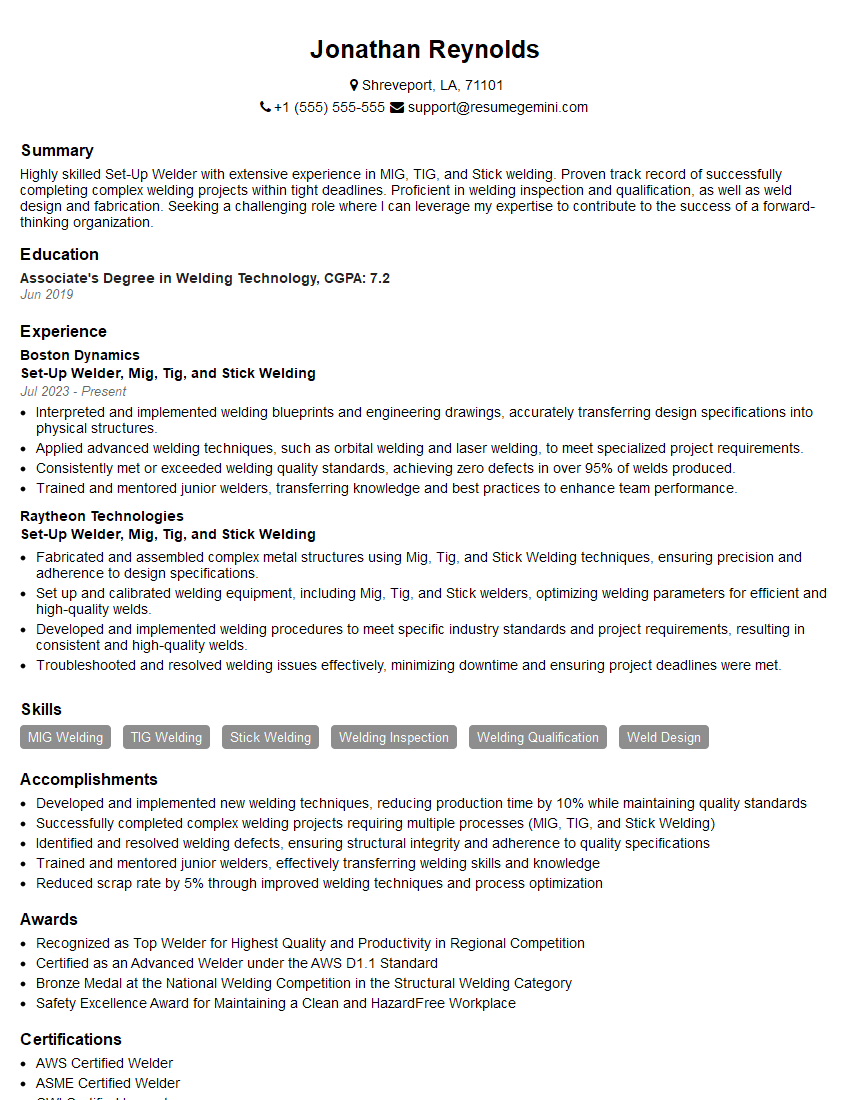

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Set-Up Welder, Mig, Tig, and Stick Welding

1. Describe the steps involved in setting up a MIG welding machine?

To set up a MIG welding machine, I follow these steps:

- Select the appropriate shielding gas and adjust the flow rate.

- Install the correct welding wire and set the wire feed speed.

- Set the voltage and amperage based on the welding process and material.

- Inspect the welding torch, nozzle, and cables for any damage.

- Ground the machine properly to ensure operator safety.

- Load the welding wire and adjust the tension to prevent birdnesting.

2. What are the key differences between MIG, TIG, and stick welding?

- MIG (Metal Inert Gas) Welding: Uses a continuously fed wire electrode in a shielding gas environment, resulting in higher deposition rates.

- TIG (Tungsten Inert Gas) Welding: Employs a non-consumable tungsten electrode and a separate filler material, offering precise control and high-quality welds.

- Stick Welding: Utilizes a consumable electrode coated with flux, producing welds with deeper penetration and less spatter.

3. Explain the factors that affect weld quality in TIG welding.

- Tungsten Electrode: Size, type, and condition affect the arc stability and weld penetration.

- Shielding Gas: Purity and flow rate influence the weld quality and prevent oxidation.

- Welding Angle: Proper angle of the torch relative to the workpiece ensures proper fusion and penetration.

- Filler Material: Type and diameter of the filler rod affect the weld strength and appearance.

- Travel Speed: Maintaining a consistent travel speed optimizes weld quality and prevents defects.

4. Describe the safety procedures for stick welding.

- Proper Clothing: Wear flame-resistant clothing, gloves, and a welding helmet.

- Ventilation: Ensure adequate ventilation to remove welding fumes and gases.

- Grounding: Ground the workpiece and welding machine to prevent electrical shock.

- Eye Protection: Use a welding helmet with the appropriate shade to protect your eyes from arc flash.

- Fire Safety: Keep a fire extinguisher nearby and be aware of potential fire hazards.

5. How do you determine the appropriate amperage for a given welding job?

- Material Thickness: Thicker materials require higher amperage for proper penetration.

- Joint Type: Butt joints generally require lower amperage than edge or corner joints.

- Welding Position: Overhead welding requires higher amperage to overcome gravity.

- Welding Process: MIG welding typically requires lower amperage compared to TIG or stick welding.

- Reference Charts: Use manufacturer-provided charts or industry standards to determine appropriate amperage ranges.

6. What are the common welding defects and how can they be prevented?

- Porosity: Trapped gases in the weld, prevented by using dry materials and adequate shielding gas.

- Lack of Fusion: Incomplete bonding between the base metal and weld, caused by insufficient heat input or poor joint preparation.

- Cracking: Fracture of the weld, avoided by using proper welding techniques, preheating, and stress relief.

- Undercut: Groove in the base metal adjacent to the weld, prevented by maintaining proper travel speed and angle.

- Spatter: Small drops of molten metal, reduced by using the correct shielding gas and proper welding parameters.

7. How do you troubleshoot a MIG welding machine that is not feeding wire?

- Check the Drive Roll: Ensure the drive roll is properly adjusted and free of debris.

- Inspect the Wire Feed Cable: Look for any kinks or damage to the cable.

- Clean the Contact Tip: Remove any spatter or oxidation from the contact tip.

- Adjust the Wire Tension: Too much tension can cause the wire to break, while too little tension can result in slipping.

- Check the Gas Flow: Ensure the shielding gas is flowing properly to prevent wire birdnesting.

8. What is the role of flux in stick welding?

- Shielding: Flux creates a protective gas shield around the weld pool, preventing oxidation.

- Deoxidation: Flux contains deoxidizers that remove oxygen from the weld pool, improving weld quality.

- Slag Formation: Flux forms a layer of slag on the weld surface, which protects it from atmospheric contaminants and needs to be removed after welding.

- Stabilization: Flux promotes arc stability and helps maintain a consistent weld pool.

9. Explain how to set up and use a pulse welding mode on a TIG welding machine.

- Adjust Pulse Settings: Set the pulse frequency, pulse duration, and peak current.

- Select Shielding Gas: Use a helium-based shielding gas for optimal pulse welding.

- Tungsten Electrode: Choose a pointed or blunt tungsten electrode depending on the desired weld profile.

- Practice Technique: Perfect the technique by practicing on scrap material before welding on actual components.

- Control Heat Input: Adjust pulse parameters to minimize heat input and reduce distortion.

10. Describe the advantages of using robotic welding in manufacturing.

- Increased Productivity: Robots can operate 24/7, resulting in higher output and reduced labor costs.

- Consistency: Robots perform welds with precise repeatability, ensuring consistent quality.

- Improved Safety: Robots can work in hazardous environments, reducing risks to human welders.

- Complex Welds: Robots can execute complex weld paths and geometries that are difficult to achieve manually.

- Reduced Material Waste: Robotic welding minimizes weld defects and scrap, leading to material savings.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Set-Up Welder, Mig, Tig, and Stick Welding.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Set-Up Welder, Mig, Tig, and Stick Welding‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Set-Up Welders typically need to have extensive knowledge of MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and Stick (Shielded Metal Arc) Welding techniques.

1. Planning and Preparation

Set-Up Welders perform the following tasks:

- Review blueprints, diagrams, and other job documentation to ascertain welding requirements.

- Plan and lay out welding assignments, and select the appropriate welding process, materials, and equipment.

2. Welding Setup and Execution

Set-Up Welders also perform the following tasks:

- Set up and prepare welding equipment, including MIG, TIG, and Stick welding machines, torches, and fixtures.

- Adjust welding parameters, such as voltage, amperage, and gas flow, to ensure optimal weld quality.

- Weld according to specifications, ensuring accuracy, precision, and adherence to quality standards.

3. Inspection and Quality Control

Set-Up Welders perform the following tasks:

- Inspect welds visually and using non-destructive testing methods to verify quality and adherence to specifications.

- Identify and correct any welding defects or deviations from standards.

4. Maintenance and Troubleshooting

Set-Up Welders perform the following tasks:

- Maintain welding equipment and ensure its proper functioning and calibration.

- Troubleshoot and resolve welding problems, identifying and rectifying any issues with equipment or processes.

Interview Tips

To help candidates ace their interview for the Set-Up Welder position, here are some tips:

1. Research the Company and Position

Research the company’s history, products or services, and company culture. This will equip you to answer questions about your fit with the company and demonstrate your interest in the position.

- Practice answering questions related to your experience and skills, focusing on quantifying your accomplishments.

- Prepare questions to ask the interviewer, demonstrating your interest in the company and the position itself.

2. Technical Proficiency and Experience

Highlight your technical proficiency in MIG, TIG, and Stick Welding, and emphasize specific accomplishments or projects where you successfully applied these skills.

- Bring examples of your welding work to the interview (if possible) to showcase your skills.

- Review welding industry standards and best practices to demonstrate your up-to-date knowledge.

3. Safety and Quality Control

Emphasize your commitment to safety and quality control in your welding practices. Discuss your experience with safety protocols and testing methodologies.

- Highlight your understanding of welding quality standards and your ability to identify and correct welding defects.

- Mention any certifications or training programs in welding safety or quality control.

4. Teamwork and Problem-Solving

Welding often involves working as part of a team and problem-solving on the job. Share examples of your collaboration skills, ability to work under pressure, and problem-solving abilities.

- Discuss your experience in troubleshooting welding issues and finding innovative solutions.

- Emphasize your willingness to learn from others and collaborate on projects.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Set-Up Welder, Mig, Tig, and Stick Welding role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.