Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sewer Line Repairer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

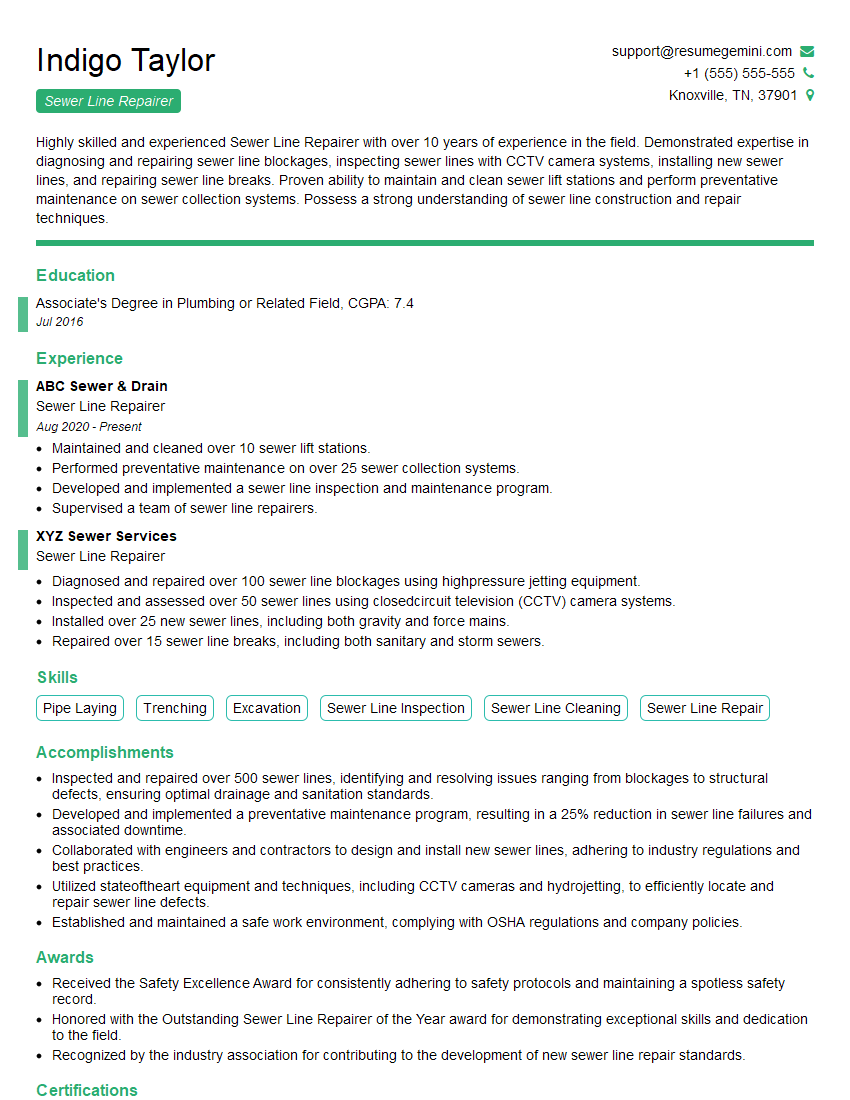

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sewer Line Repairer

1. Can you describe the steps involved in repairing a collapsed sewer line using the cured-in-place pipe lining method?

In the cured-in-place pipe lining method, the steps involved are as follows:

- Inspection and Cleaning: The collapsed pipe is inspected using a camera to assess the damage. The pipe is then cleaned to remove debris and grease.

- Pipe Preparation: The collapsed pipe is prepared by removing any protruding debris or roots. The surface is then sanded to create a smooth surface for the liner.

- Liner Insertion: A flexible liner made of a resin-impregnated fabric is inserted into the collapsed pipe. The liner is inflated using water or air to conform to the shape of the pipe.

- Curing: The liner is cured using heat or UV light, which causes the resin to harden and form a new, strong pipe within the collapsed pipe.

- Relining: Once the liner is cured, it is connected to the existing sewer system and the new pipe is put into service.

2. What are the advantages and disadvantages of using trenchless sewer line repair methods compared to traditional excavation methods?

Advantages of Trenchless Methods:

- Less excavation required, reducing disruption to the surrounding area.

- Faster installation times, leading to cost savings.

- Environmentally friendly, as it minimizes soil disturbance and waste generation.

- Suitable for repairing pipes in difficult-to-access areas, such as under buildings or roads.

Disadvantages of Trenchless Methods:

- May not be suitable for all types of sewer line repairs, such as major blockages or severe pipe damage.

- Requires specialized equipment and trained technicians, which can increase costs.

- Can be more expensive than traditional excavation methods, depending on the complexity of the repair.

3. How do you determine the appropriate repair method for a damaged sewer line?

The appropriate repair method for a damaged sewer line is determined based on several factors:

- Severity of Damage: The extent and type of damage to the sewer line will influence the choice of repair method.

- Location of Damage: The location of the damaged section, such as its depth and accessibility, can affect the feasibility of different repair methods.

- Type of Sewer Line: The material and size of the sewer line will influence the choice of repair method, as some methods may not be suitable for all types of pipes.

- Cost and Time Constraints: The budget and time available for the repair will also play a role in selecting the most appropriate method.

4. What safety precautions should be taken when working on a sewer line repair?

When working on a sewer line repair, it is crucial to adhere to the following safety precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator.

- Ventilate the work area to prevent the accumulation of hazardous gases.

- Use barricades and warning signs to alert others of the work area.

- Be aware of potential hazards such as live electrical wires or sharp objects.

- Follow proper lockout/tagout procedures to prevent accidental equipment activation.

5. What is the importance of using high-quality materials and equipment in sewer line repairs?

Using high-quality materials and equipment in sewer line repairs is crucial for several reasons:

- Durability: High-quality materials can withstand the harsh conditions found in sewer lines, ensuring a long-lasting repair.

- Reliability: Reliable equipment minimizes the risk of breakdowns or malfunctions, preventing delays or complications during the repair process.

- Safety: Using proper equipment and materials helps protect workers and the surrounding environment from potential hazards.

- Cost-effectiveness: While high-quality materials and equipment may have a higher initial cost, they can save money in the long run by reducing the need for frequent repairs or replacements.

6. How do you stay updated with the latest technologies and best practices in sewer line repair?

To stay updated with the latest technologies and best practices in sewer line repair, I follow these strategies:

- Attend industry conferences and workshops: This provides opportunities to learn about new technologies and network with experts.

- Read industry publications and research papers: These sources offer valuable insights into advancements in the field.

- Participate in training programs: Manufacturers and industry organizations offer training programs to update technicians on the latest methods and technologies.

- Seek certifications: Certifications, such as the National Association of Sewer Service Companies (NASSCO) PACP certification, demonstrate proficiency in industry standards and best practices.

7. Describe a challenging sewer line repair project you encountered and how you overcame the challenges.

In one instance, I encountered a collapsed sewer line under a busy intersection. The challenge was to repair the line without disrupting traffic flow. We utilized a trenchless method known as pipe bursting, which involved pulling a new pipe through the damaged section while simultaneously breaking and displacing the old pipe. By carefully planning and coordinating with traffic control, we were able to complete the repair with minimal disruption.

8. How do you handle working with different types of sewer line materials, such as PVC, clay, and cast iron?

Each type of sewer line material requires specific knowledge and techniques for repair. For PVC pipes, I use specialized solvent welding techniques to ensure a strong and leak-proof connection. When working with clay pipes, I take extra care to support the pipe and use flexible couplings to accommodate any movement. Cast iron pipes require special tools and experience to cut and join the sections properly.

9. What are the common causes of sewer line problems and how do you troubleshoot them?

Common causes of sewer line problems include: tree root intrusion, corrosion, blockages, and misalignment. To troubleshoot, I conduct a thorough inspection using a camera to identify the exact location and cause of the issue. Based on the findings, I recommend the most appropriate repair method to address the underlying problem and prevent future occurrences.

10. How do you ensure that the repaired sewer line meets code requirements and industry standards?

Before starting any repair, I familiarize myself with the applicable building codes and industry standards. During the repair process, I adhere to these guidelines to ensure that the finished work meets or exceeds the required standards. I also conduct thorough testing and inspection to verify the integrity of the repaired line before putting it back into service.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sewer Line Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sewer Line Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sewer Line Repairers are responsible for maintaining and repairing sewer lines and related infrastructure. Their key job responsibilities include:

1. Inspect and Assess Sewer Lines

Inspecting and assessing sewer lines to identify blockages, leaks, and other issues using specialized equipment such as cameras and sensors.

- Locate and mark underground sewer lines

- Conduct video inspections to identify structural defects, blockages, and root intrusion

2. Diagnose and Troubleshoot Sewer Line Issues

Diagnosing and troubleshooting sewer line issues to determine the cause and appropriate repair method.

- Analyze inspection data to identify the source and nature of the problem

- Recommend and implement repair solutions based on the assessment

3. Repair and Replace Sewer Lines

Repairing and replacing sewer lines using various techniques and materials, including trenchless repair methods.

- Excavate and replace damaged sewer pipes

- Install new sewer lines and connect them to existing systems

4. Maintain and Inspect Sewer Systems

Maintaining and inspecting sewer systems to ensure proper operation and prevent future issues.

- Regularly clean and flush sewer lines to prevent blockages

- Inspect and repair manholes, catch basins, and other sewer components

Interview Tips

Preparing for an interview for a Sewer Line Repairer position requires both technical knowledge and an understanding of the industry. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Research the company you’re applying to and the sewer line repair industry. This will help you understand their specific needs and the current trends and challenges in the field.

- Visit the company’s website to learn about their services, values, and recent projects

- Read industry publications and attend trade shows to stay up-to-date on new technologies and best practices

2. Highlight Relevant Skills and Experience

In your resume and interview, highlight your relevant skills and experience in sewer line repair. Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Emphasize your proficiency in sewer inspection and assessment techniques

- Showcase your experience in repairing and replacing sewer lines using various methods

3. Be Prepared to Discuss Safety and Regulations

Safety is paramount in sewer line repair, and employers will want to know that you’re aware of and committed to safety protocols. Be prepared to discuss your knowledge of OSHA regulations and industry best practices.

- Explain how you ensure your own safety and the safety of others on the job

- Discuss your understanding of the environmental regulations related to sewer line repair

4. Demonstrate Problem-Solving and Critical Thinking Skills

Sewer line repair often involves unexpected challenges and requires problem-solving and critical thinking skills. In the interview, provide examples of how you have successfully diagnosed and resolved complex sewer line issues.

- Describe a situation where you identified a unique problem and developed an innovative solution

- Explain how you analyze inspection data and make informed decisions

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Sewer Line Repairer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Sewer Line Repairer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.