Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sewer Pipe Layer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

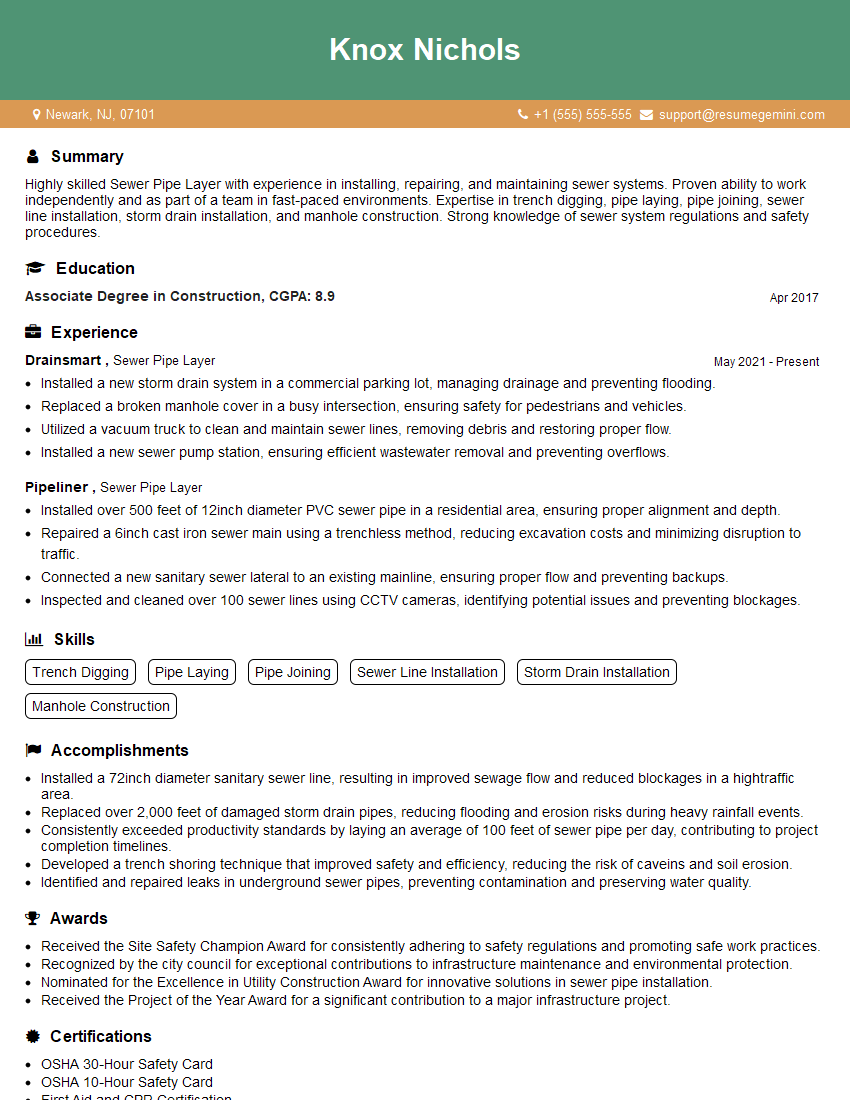

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sewer Pipe Layer

1. How do you ensure accurate measurements for sewer pipe installation?

To ensure accurate measurements for sewer pipe installation, I adhere to several key steps:

- Proper Equipment: I use calibrated measuring tapes, levels, and other tools to obtain precise measurements.

- Reference Points: I identify fixed reference points, such as property boundaries or existing structures, to establish accurate baselines.

- Multiple Readings: I take multiple measurements from different angles and positions to minimize errors.

- Cross-Checking: I cross-check my measurements with colleagues or supervisors to verify their accuracy.

- Documentation: I carefully record all measurements and calculations for future reference.

2. What are the safety precautions you take when working in confined spaces, such as sewer pipes?

Ventilation:

- Ensure proper ventilation by using blowers or mechanical ventilation systems.

Fall Protection:

- Wear a harness and safety line when working in elevated areas.

- Secure ladders or platforms to prevent slipping or falling.

Gas Monitoring:

- Use gas detectors to monitor levels of toxic or flammable gases.

- Work in teams and have a spotter outside the confined space for emergency assistance.

Electrical Hazards:

- Test electrical equipment before use and use proper grounding techniques.

- Avoid working near live wires or power sources.

3. How do you determine the appropriate pipe diameter and material for a given sewer system design?

To determine the appropriate pipe diameter and material for a sewer system design, I consider several factors:

- Flow Rate: I calculate the estimated flow rate based on the population, land use, and other factors.

- Pipe Slope: I determine the optimal slope to ensure proper drainage and prevent blockages.

- Soil Conditions: I assess the soil type and moisture content to select materials resistant to corrosion and settlement.

- Codes and Regulations: I follow applicable building codes and industry standards for pipe materials and diameters.

- Cost and Availability: I consider the cost and availability of different pipe materials within the project budget.

4. Describe the steps involved in installing a sewer pipe connection to a building.

The steps involved in installing a sewer pipe connection to a building include:

- Excavation: Digging a trench from the building to the main sewer line.

- Pipe Installation: Laying the sewer pipe in the trench, ensuring proper slope and support.

- Jointing: Joining the sewer pipe sections using couplings, gaskets, or solvent welding.

- Backfilling: Filling the trench with soil or gravel to provide support and prevent movement.

- Connection: Connecting the sewer pipe to the building’s plumbing system.

- Testing: Performing leak and pressure tests to ensure proper installation and functionality.

5. How do you handle and dispose of waste materials encountered during sewer pipe installation?

To handle and dispose of waste materials encountered during sewer pipe installation, I follow these steps:

- Proper Containment: I store waste materials, such as excavated soil and debris, in designated containers.

- Sorting and Segregation: I segregate waste materials into recyclable and non-recyclable components.

- Removal and Disposal: I arrange for the safe removal and disposal of waste materials through licensed waste management companies.

- Environmental Compliance: I adhere to all environmental regulations and guidelines for waste management.

6. Explain the different types of sewer pipe jointing methods and their advantages and disadvantages.

There are several types of sewer pipe jointing methods:

- Bell and Spigot: Fits the spigot end of one pipe into the bell end of another, sealed with caulking or gaskets.

- Mechanical Joints: Uses bolts or clamps to secure the pipes, resistant to movement.

- Solvent Welding: Uses a special solvent to dissolve and fuse the pipe ends together, creating a strong bond.

- Compression Fittings: Uses rubber gaskets to seal pipes, suitable for flexible pipes.

7. How do you calculate the slope and grade of a sewer pipe?

To calculate the slope and grade of a sewer pipe, I use the following formula:

- Slope: Slope = (Change in Elevation) / (Horizontal Distance)

- Grade: Grade = (Slope) * 100

8. Describe the process of installing a manhole in a sewer system.

The process of installing a manhole in a sewer system involves:

- Excavation: Digging a circular pit to the required depth.

- Base Preparation: Preparing the base with concrete or gravel for stability.

- Manhole Construction: Assembling the manhole frame and cover using precast concrete or brick.

- Pipe Connections: Connecting the sewer pipes to the manhole.

- Backfilling: Filling around the manhole with compacted soil or gravel.

9. Explain the importance of maintaining proper flow rates in sewer pipes.

Maintaining proper flow rates in sewer pipes is crucial for:

- Prevention of Clogging: Adequate flow rates help prevent solids from settling and causing blockages.

- Efficient Drainage: Proper flow rates ensure that wastewater is discharged smoothly without overflows.

- Pipe Integrity: Excessive flow rates can damage pipes and lead to leaks or ruptures.

- Reduced Odor: Maintaining proper flow rates minimizes the stagnation of wastewater, reducing odors.

10. Discuss the challenges you have encountered in your previous role as a Sewer Pipe Layer and how you overcame them.

As a Sewer Pipe Layer, I have faced various challenges, including:

- Working in Confined Spaces: Working in tight and confined spaces requires careful planning and safety precautions.

- Hazardous Conditions: Handling sewage and working in wet or damp environments can pose health and safety risks.

- Uneven Ground: Laying pipes on uneven or sloped ground requires adjustments to ensure proper grades and alignment.

- Time Constraints: Meeting deadlines while maintaining quality and safety standards can be challenging.

- Physical Demands: The job involves heavy lifting, excavation, and prolonged standing.

To overcome these challenges, I rely on my technical skills, safety training, and adherence to industry best practices. I prioritize safety measures, use the appropriate tools and equipment, and seek support from colleagues when needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sewer Pipe Layer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sewer Pipe Layer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sewer pipe layers are responsible for installing, repairing, and replacing sewer pipes. They work with a variety of materials, including PVC, polyethylene, and concrete. They may also be responsible for connecting sewer pipes to homes and businesses.

1. Installing Sewer Pipes

Sewer pipe layers typically install sewer pipes by digging a trench, laying the pipe in the trench, and then covering the pipe with dirt. They may use a variety of tools to dig the trench, including a backhoe, shovel, and pickaxe. They may also use a variety of tools to lay the pipe, including a pipe wrench, a level, and a tamper.

2. Repairing Sewer Pipes

Sewer pipe layers may also repair sewer pipes that have been damaged or broken. They may repair the pipe by replacing a section of the pipe, patching the pipe, or lining the pipe. They may use a variety of tools to repair the pipe, including a saw, a hammer, and a wrench.

3. Replacing Sewer Pipes

Sewer pipe layers may also replace sewer pipes that are old or damaged. They may replace the pipe by digging a new trench and laying a new pipe in the trench. They may also replace the pipe by using a trenchless method, which involves inserting a new pipe into the old pipe without digging a new trench.

4. Connecting Sewer Pipes to Homes and Businesses

Sewer pipe layers may also connect sewer pipes to homes and businesses. They may connect the pipe to the home or business by digging a trench and laying the pipe in the trench. They may also connect the pipe to the home or business by using a trenchless method, which involves inserting a new pipe into the old pipe without digging a new trench.

Interview Tips

Preparing for an interview for a sewer pipe layer position can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Before the interview, take some time to research the company and the position. This will help you understand the company’s culture and the specific requirements of the job. You can research the company by visiting its website and reading its annual reports. You can research the position by reading the job description and talking to people who work in similar positions.

2. Practice Answering Common Interview Questions

There are several common interview questions that you are likely to be asked. By practicing answering these questions, you can improve your chances of giving clear and concise answers. Some common interview questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

- What are your career goals?

3. Prepare Questions to Ask the Interviewer

At the end of the interview, you will likely be given the opportunity to ask the interviewer questions. This is a great opportunity to learn more about the company and the position. Some good questions to ask include:

- What are the biggest challenges facing the company?

- What are the opportunities for advancement?

- What is the company culture like?

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the job and that you respect their time.

5. Be Yourself and Be Confident

The most important thing is to be yourself and be confident. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be confident in your abilities and your experience, and let the interviewer see your passion for the job.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Sewer Pipe Layer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Sewer Pipe Layer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.