Are you gearing up for an interview for a Sewing Machine Bobbin Winder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Sewing Machine Bobbin Winder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

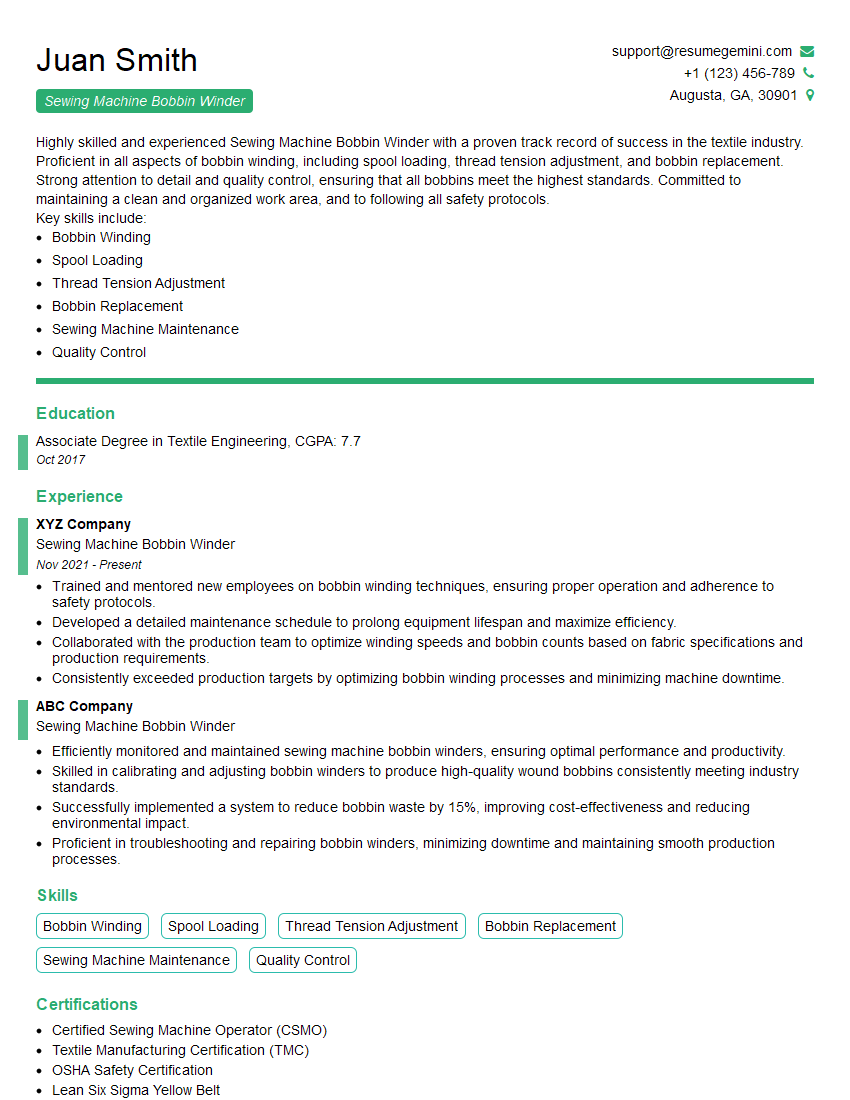

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sewing Machine Bobbin Winder

1. How do you ensure that the bobbins are wound correctly and evenly?

- Regularly inspect and maintain the bobbin winder to ensure proper functioning.

- Check that the thread tension is set correctly and maintain the settings for optimal results.

- Use high-quality thread to prevent breakage and ensure smooth winding.

- Conduct quality checks on the wound bobbins to ensure they meet specifications and provide consistent performance.

2. Describe the different types of bobbins and how to handle them appropriately.

Plastic Bobbins

- Lightweight and inexpensive.

- Handle carefully to avoid cracking.

- May require special adapters for certain machines.

Metal Bobbins

- Durable and can withstand high winding speeds.

- More expensive than plastic bobbins.

- Check for burrs or imperfections that may damage the thread.

3. What are the common troubleshooting steps you take when facing issues with the bobbin winder?

- Check for any blockages in the thread path.

- Ensure the bobbin winder is properly attached and aligned.

- Adjust the tension settings to optimize bobbin winding.

- Inspect the bobbin for any damage or defects that may affect performance.

4. How do you maintain the bobbin winder to ensure optimal performance?

- Regular cleaning to remove dust and debris.

- Lubricate moving parts as per manufacturer’s recommendations.

- Inspect and replace worn or damaged components.

- Use high-quality lubricants to maintain smooth and efficient operation.

5. What safety precautions should be followed when operating the bobbin winder?

- Wear appropriate safety gear, including safety glasses.

- Keep the work area clear of obstacles and distractions.

- Never attempt to repair or adjust the bobbin winder while it is running.

- Follow manufacturer’s instructions and warnings for safe operation.

6. Describe the different types of thread used for bobbin winding and their respective advantages.

Cotton Thread

- Strong and durable.

- Suitable for a wide range of fabrics.

- Available in a variety of colors and thicknesses.

Polyester Thread

- Synthetic thread with high tensile strength.

- Resistant to shrinking and fading.

- Often used for decorative stitching and embroidery.

7. How do you handle and store bobbins to prevent damage and ensure their longevity?

- Store bobbins in a cool, dry place away from sunlight.

- Keep bobbins organized to prevent tangling.

- Inspect bobbins regularly for any signs of damage or wear.

- Use bobbin cases or organizers to protect bobbins during storage.

8. Explain the process of winding a bobbin using a manual bobbin winder.

- Insert the empty bobbin onto the winder spindle.

- Pull the thread through the thread guide and onto the bobbin.

- Turn the winder handle to wind the thread onto the bobbin.

- Continue winding until the bobbin is full or the desired length is reached.

9. Describe the steps involved in replacing a bobbin in a sewing machine.

- Open the bobbin cover or release the bobbin holder.

- Remove the empty bobbin.

- Insert the new bobbin into the holder.

- Close the cover or lock the bobbin holder.

- Pull the thread through the tension discs and into the needle.

10. What techniques can be employed to improve the accuracy and efficiency of the bobbin winding process?

- Use a high-quality bobbin winder with adjustable tension settings.

- Ensure the bobbin is properly aligned on the spindle.

- Wind the bobbin at a consistent speed to maintain even tension.

- Regularly inspect the thread and bobbin for any defects or tangles.

- Utilize automated bobbin winders for increased productivity and consistency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sewing Machine Bobbin Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sewing Machine Bobbin Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sewing Machine Bobbin Winders are responsible for the smooth operation of sewing machines by efficiently winding bobbins with thread for the sewing process. Their key responsibilities include:

1. Bobbin Winding

Expertly operating bobbin winding machines to wind thread onto bobbins.

- Selecting the appropriate thread and adjusting machine settings.

- Monitoring winding tension and quality to ensure even bobbin formation.

2. Production Monitoring

Maintaining a productive work environment by tracking bobbin output and identifying any potential issues.

- Performing regular machine maintenance and troubleshooting minor issues.

- Ensuring a steady supply of bobbins to support sewing operations.

3. Quality Control

Inspecting bobbins for defects and ensuring they meet quality standards.

- Identifying and removing substandard bobbins to prevent production delays.

- Adhering to established quality control procedures.

4. Material Handling

Effectively managing thread and bobbin inventory, ensuring timely supply to sewing operations.

- Loading and unloading bobbin winding machines as needed.

- Maintaining a clean and organized work area.

Interview Tips

Preparing thoroughly for a Sewing Machine Bobbin Winder interview can significantly increase your chances of success. Here are some valuable tips to help you ace the interview:

1. Research the Company and Role

Familiarize yourself with the company’s website, industry reputation, and the specific role you are applying for. This will demonstrate your interest and enthusiasm.

2. Practice Answering Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses that highlight your skills and experience. Consider using the STAR method to structure your answers and provide specific examples.

3. Emphasize Your Attention to Detail

As a Sewing Machine Bobbin Winder, attention to detail is crucial. Emphasize your ability to identify and correct defects, ensuring the production of high-quality bobbins.

4. Highlight Your Problem-Solving Abilities

Interviewers seek candidates who can effectively troubleshoot and resolve issues. Showcase your ability to identify problems, analyze possible solutions, and implement practical fixes.

5. Demonstrate Your Teamwork Skills

Sewing Machine Bobbin Winders often work as part of a team. Highlight your ability to collaborate with others, communicate effectively, and support the overall production process.

6. Be Punctual and Professional

Punctuality and professionalism create a positive first impression. Arrive on time for your interview and dress appropriately to show that you value the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sewing Machine Bobbin Winder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.