Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Sewing Machine Repairer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Sewing Machine Repairer so you can tailor your answers to impress potential employers.

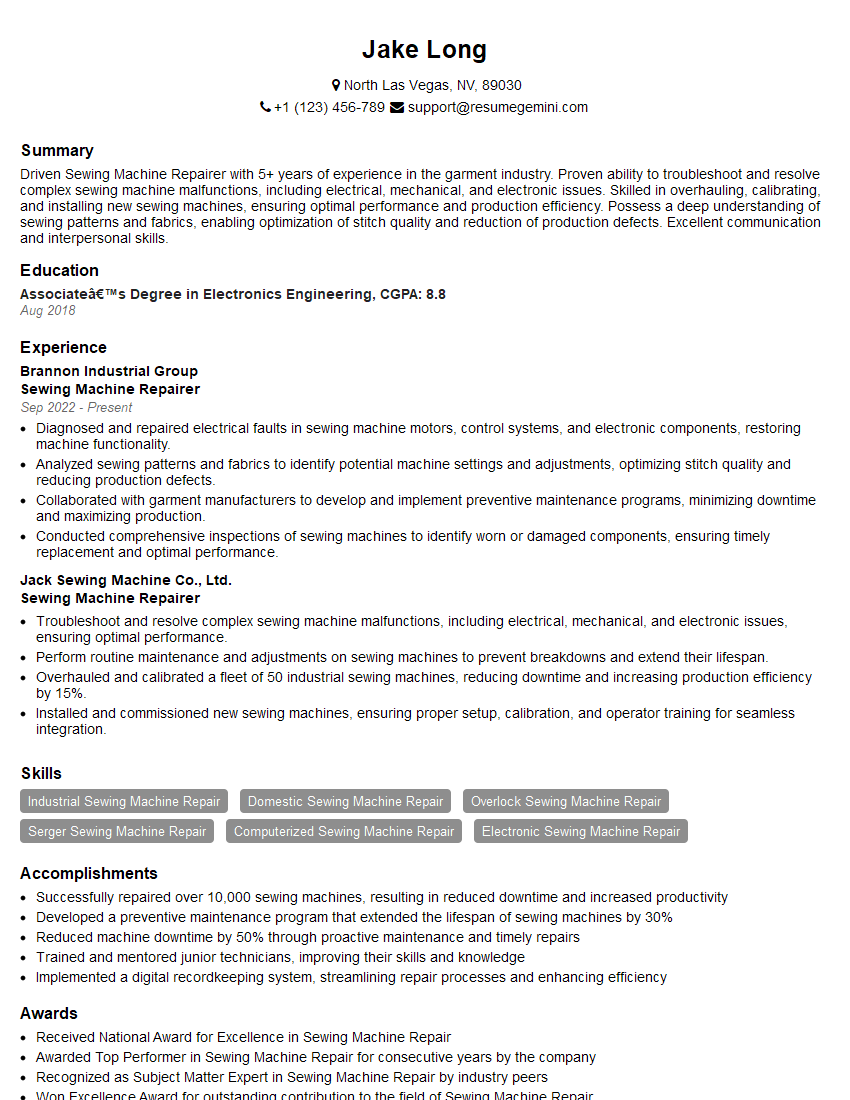

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sewing Machine Repairer

1. What are the most common types of sewing machine repairs?

- Tension problems

- Bobbin issues

- Needle breakage

- Thread jamming

- Electrical faults

2. How do you troubleshoot a sewing machine problem?

Check the basics

- Make sure the machine is properly threaded.

- Check the needle for damage or bending.

- Ensure the bobbin is correctly wound.

Inspect the machine

- Look for loose or broken parts.

- Check the wiring for any damage.

- Listen for unusual noises or vibrations.

Test the machine

- Sew a few stitches on a scrap piece of fabric.

- Observe the stitch quality and listen for any unusual sounds.

- Adjust the tension or other settings as needed.

3. What are the common causes of needle breakage?

- Using the wrong needle size or type for the fabric.

- A bent or damaged needle.

- Improper threading.

- Fabric that is too thick or dense.

- A dull or worn-out needle.

4. How do you adjust the tension on a sewing machine?

- Locate the tension dial on the machine.

- Turn the dial to increase or decrease the tension.

- Sew a few stitches on a scrap piece of fabric to test the tension.

- Adjust the tension until the stitches are even and secure.

5. What are the different types of sewing machine feet?

- All-purpose foot

- Buttonhole foot

- Zipper foot

- Blind hem foot

- Overcasting foot

6. How do you replace a bobbin?

- Open the bobbin case.

- Remove the old bobbin.

- Wind the new bobbin with thread.

- Insert the new bobbin into the bobbin case.

- Close the bobbin case.

7. What are the most common electrical faults in sewing machines?

- Faulty power cord

- Loose or broken wiring

- Damaged motor

- Faulty switch

- Overheating

8. How do you test an electrical fault in a sewing machine?

- Use a multimeter to check for continuity in the power cord and wiring.

- Inspect the motor for any damage or burning.

- Test the switch for proper operation.

- Check for any loose or broken connections.

9. What are the safety precautions that should be taken when repairing a sewing machine?

- Unplug the machine from the power source before starting any repairs.

- Wear appropriate safety gear, such as safety glasses and gloves.

- Use caution when working with sharp objects.

- Do not attempt to repair electrical components if you are not qualified.

- Refer to the manufacturer’s instructions for specific safety precautions for the particular machine.

10. What are the most important qualities of a successful sewing machine repairer?

- Strong technical skills

- Excellent problem-solving abilities

- Excellent customer service skills

- Attention to detail

- Ability to work independently

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sewing Machine Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sewing Machine Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Sewing Machine Repairer is a highly skilled technician responsible for maintaining and repairing all types of sewing machines. They work in a variety of settings, including garment factories, textile mills, and repair shops.

1. Troubleshooting and Repairing Machines

The primary responsibility of a Sewing Machine Repairer is to troubleshoot and repair sewing machines. This involves:

- Diagnosing the problem with the machine

- Replacing or repairing any damaged parts

- Calibrating and adjusting the machine to ensure it is functioning properly

2. Maintenance and Inspection

Sewing Machine Repairers also conduct regular maintenance and inspections to prevent problems from occurring. This involves:

- Cleaning and lubricating the machine

- Inspecting the machine for any signs of wear or damage

- Replacing any worn or damaged parts before they cause a problem

3. Customer Service

Sewing Machine Repairers also provide customer service to their clients. This involves:

- Answering questions about the machine

- Providing instruction on how to use the machine properly

- Scheduling appointments for repairs

4. Record Keeping

Sewing Machine Repairers must also keep accurate records of their work. This involves:

- Documenting the repairs that they have performed

- Maintaining a log of all maintenance and inspections

- Keeping track of the parts that have been replaced

Interview Tips

Preparing for a Sewing Machine Repairer interview is essential to ace the interview and land the job. Here are some tips to help you prepare:

1. Research the Company and the Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you better understand the requirements of the position and what the interviewer will be looking for.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?” Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Bring a Portfolio of Your Work

If you have any samples of your work, such as repaired sewing machines or documentation of your repairs, bring them to the interview. This will give the interviewer a better sense of your skills and experience.

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic and positive about the position and the company. Be sure to convey your enthusiasm and positive attitude during the interview. This will make a good impression on the interviewer and increase your chances of getting the job.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Sewing Machine Repairer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Sewing Machine Repairer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.