Are you gearing up for a career in Shaft Mechanic? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Shaft Mechanic and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

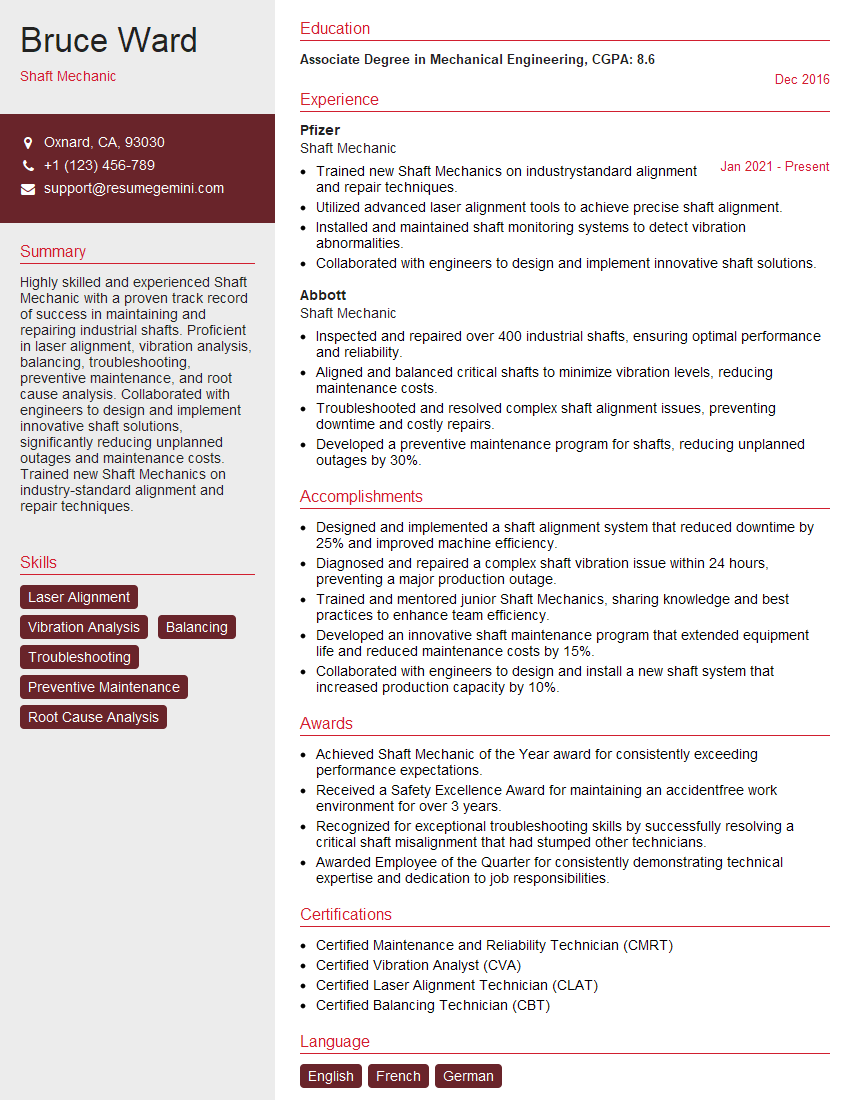

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shaft Mechanic

1. What are the different types of shaft couplings and their applications?

- Rigid couplings: Connect two shafts without allowing any relative movement between them. Used in applications where precise alignment is required and high torque is transmitted.

- Flexible couplings: Allow for some degree of misalignment between shafts and absorb vibrations. Used in applications where shafts are not perfectly aligned or where there are dynamic loads.

- Spring couplings: Use coil springs to accommodate misalignment and damp vibrations. Suitable for high-speed applications.

- Gear couplings: Use meshing gears to transmit torque and allow for angular misalignment. Offer high torque capacity and low backlash.

2. Explain the process of shaft alignment and the different methods used.

- Measures the distance between the rims or faces of the shafts’ coupling hubs.

- Uses a dial indicator or laser alignment tool to detect misalignment.

- Mounts dial indicators on the shaft hubs and uses them to measure the relative movement between the shafts.

- Rotates the shafts and observes the dial indicator readings to determine misalignment.

Rim and face method

Reverse dial indicator method

3. Describe the different types of bearings used in shaft systems and their advantages and disadvantages.

- Rolling element bearings: Use balls or rollers to support the shaft and reduce friction. Advantages include high efficiency, long life, and ability to handle radial and thrust loads.

- Plain bearings (bushings): Use a sliding contact surface between the shaft and the bearing. Advantages include low cost, ability to operate with minimal lubrication, and tolerance of misalignment.

- Hydrodynamic bearings: Use a thin film of oil to separate the shaft from the bearing. Advantages include very low friction and long life, but require precise lubrication and can be sensitive to contamination.

4. What are the common causes of shaft failure and how can they be prevented?

- Misalignment: Can cause bending stresses and premature bearing failure.

- Overloading: Exceeding the shafts’ capacity can lead to bending, torsional, or buckling failure.

- Fatigue: Repeated cyclic loads can weaken the shaft over time, leading to failure.

- Corrosion: Can weaken the shaft and reduce its fatigue strength.

Prevention

- Proper shaft alignment and balancing.

- Appropriate selection of shafts and bearings for the operating conditions.

- Load monitoring and overload protection.

- Corrosion protection measures, such as coatings or inhibitors.

5. Explain the concept of critical speed and its importance in shaft design.

Critical speed is the rotational speed at which a shaft begins to experience excessive vibration. This occurs due to resonance between the shaft’s natural frequency and the operating speed. Excessive vibration can lead to fatigue failure and other problems.

It is important to design shafts to operate below their critical speed or to implement measures to mitigate vibration at critical speeds.

6. What are the key factors to consider when selecting a shaft material?

- Tensile strength: Ability to withstand axial loads.

- Yield strength: Ability to withstand plastic deformation without failure.

- Fatigue strength: Resistance to failure under repeated cyclic loads.

- Corrosion resistance: Ability to resist corrosion in the operating environment.

- Machinability: Ease of machining and fabrication.

7. How do you ensure proper lubrication of a shaft system?

- Lubrication type: Selecting the appropriate lubricant for the operating conditions.

- Lubrication method: Using grease, oil, or other methods to apply lubrication.

- Lubrication frequency: Establishing a regular schedule for lubrication.

- Lubrication system: Implementing an automated or manual lubrication system to ensure consistent and reliable lubrication.

8. Describe the role of vibration analysis in shaft maintenance.

- Detecting misalignment: Vibration patterns can indicate misalignment between shafts and bearings.

- Identifying bearing problems: Vibration analysis can detect bearing wear, pitting, or other defects.

- Monitoring shaft balance: Vibration can indicate imbalances in rotating shafts.

- Predicting shaft failure: Advanced vibration analysis techniques can detect and predict shaft failures before they occur.

9. What are the common safety precautions that need to be observed when working with shaft systems?

- Lockout/tagout: Ensures that shafts and other rotating equipment are isolated from power sources before performing maintenance.

- Guarding: Protect personnel from rotating shafts and other hazards.

- Proper clothing and PPE: Wear appropriate clothing and personal protective equipment to prevent injury from flying debris or hot surfaces.

10. How do you stay up to date with the latest developments in shaft mechanics?

- Attending industry seminars and conferences.

- Reading technical journals and articles.

- Participating in online forums and discussion groups.

- Networking with other professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shaft Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shaft Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Shaft Mechanics are skilled technicians responsible for maintaining and repairing rotating shafts and their associated components within industrial settings. They play a crucial role in ensuring the smooth operation and efficiency of machinery.

1. Shaft Maintenance and Inspection

Regularly inspect shafts for wear, misalignment, vibration, and other potential issues.

- Use precision measuring tools to ensure proper dimensions and clearances.

- Monitor shaft performance indicators such as temperature, speed, and torque.

2. Troubleshooting and Repair

Diagnose and resolve shaft-related problems such as misalignment, vibration, or seal failures.

- Disassemble equipment, replace worn components, and reassemble systems.

- Adjust and balance rotating shafts to optimize performance and reduce vibration.

3. Preventive Maintenance

Conduct routine maintenance tasks to prevent unexpected failures and extend shaft life.

- Lubricate bearings and seals to minimize friction and wear.

- Monitor oil levels and adjust as necessary to ensure proper lubrication.

4. Collaboration and Communication

Work closely with other technicians, engineers, and plant operators to coordinate maintenance activities.

- Communicate shaft condition, repair recommendations, and project updates to relevant stakeholders.

- Participate in team discussions to identify potential shaft issues and develop solutions.

Interview Tips

Preparing for a Shaft Mechanic interview requires thorough research on the industry, specific job requirements, and effective interview techniques.

1. Research the Industry and Company

Familiarize yourself with the industry terminology, common shaft maintenance practices, and the organization’s business operations.

- Review industry publications and online resources to stay updated on advancements.

- Visit the company website to learn about their products, services, and maintenance processes.

2. Practice Common Interview Questions

Anticipate frequently asked interview questions and prepare well-structured answers that highlight your skills and experience.

- Describe your experience with shaft inspection and troubleshooting.

- Explain your knowledge of shaft alignment and balancing techniques.

- Discuss your preventive maintenance strategies to minimize shaft failures.

3. Showcase Your Hands-On Skills

Emphasize your ability to diagnose and repair shaft issues through practical examples.

- Describe a complex shaft repair project you successfully completed.

- Explain how you troubleshoot and solve common shaft vibration problems.

4. Highlight Safety and Communication Skills

Stress the importance of safety protocols in your work and demonstrate your communication skills.

- Describe your adherence to safety guidelines and proper handling of hazardous materials.

- Discuss your experience in collaborating with other team members and effectively conveying technical information.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Shaft Mechanic, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Shaft Mechanic positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.