Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Shaft Sinker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Shaft Sinker so you can tailor your answers to impress potential employers.

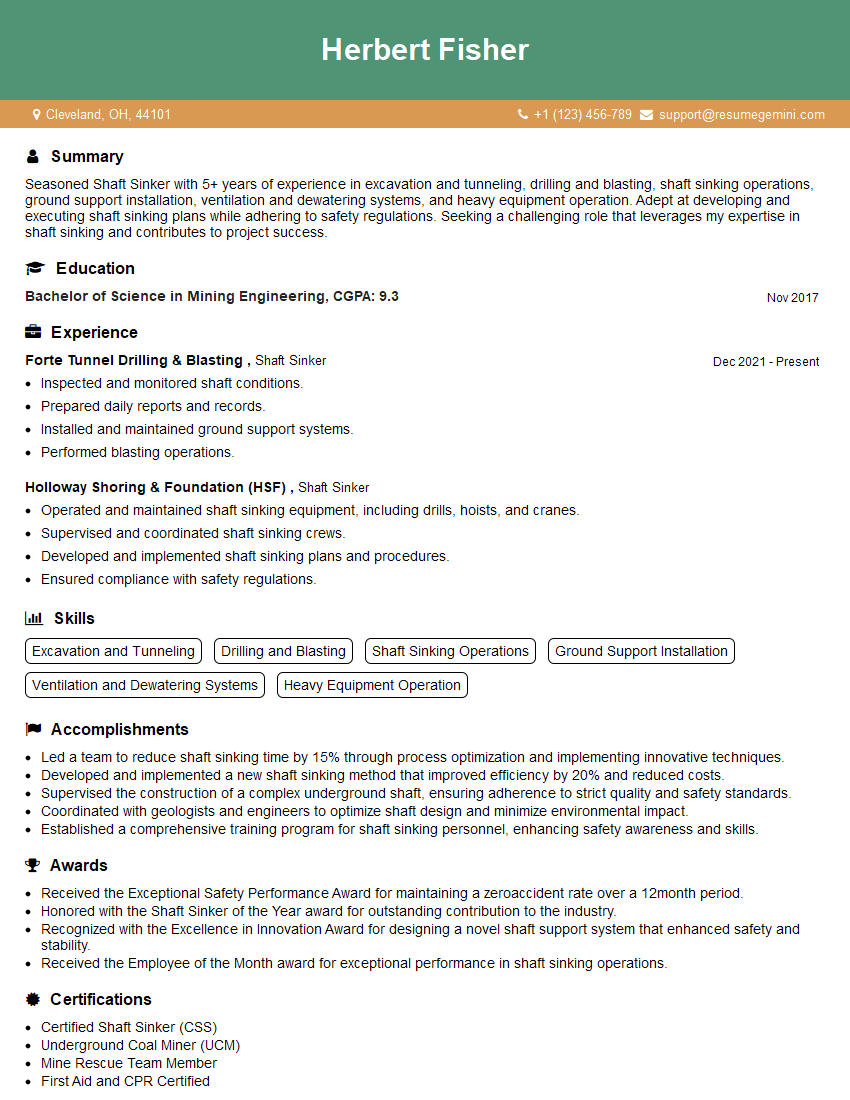

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shaft Sinker

1. Explain the steps involved in shaft sinking from the very beginning?

The steps involved in shaft sinking include:

- Planning and design: This involves determining the location of the shaft, its depth, diameter, and other specifications. It also includes planning for ground control, ventilation, and hoisting systems.

- Site preparation: This involves clearing and leveling the land where the shaft will be located. It may also involve building access roads, power supply, and other infrastructure.

- Shaft excavation: This is the process of excavating the shaft using various methods such as drilling, blasting, or freezing. Ground control measures, such as rock bolts, shotcrete, and liners, are installed to ensure the stability of the shaft.

- Shaft lining: This involves installing a lining inside the excavated shaft. The lining can be made of concrete, steel, or other materials and serves to protect the shaft from groundwater, rock falls, and other hazards.

- Shaft equipping: This involves installing the necessary equipment in the shaft, such as hoisting systems, ventilation systems, and communication systems.

- Commissioning and operation: This involves testing and commissioning the shaft to ensure that it is operating safely and efficiently.

2. What are the different methods of shaft sinking?

Drilling and blasting

- This is the most common method of shaft sinking and involves drilling holes into the rock, inserting explosives, and blasting the rock to create the shaft.

Raise boring

- This method involves using a large rotating cutter head to excavate the shaft from the bottom up.

Freezing

- This method involves freezing the ground around the shaft location, creating a stable ice wall. The shaft is then excavated within the ice wall.

Shield tunneling

- This method involves using a large shield to excavate the shaft and install the lining simultaneously.

3. What are the major safety considerations in shaft sinking?

- Ground control: This involves ensuring the stability of the shaft during excavation and lining installation to prevent rock falls, cave-ins, and other hazards.

- Ventilation: Adequate ventilation is essential to remove dust, gases, and other contaminants from the shaft.

- Hoisting safety: This involves ensuring the safe operation of hoisting systems, including proper maintenance, operator training, and emergency procedures.

- Electrical safety: This involves ensuring the proper installation and maintenance of electrical systems, including grounding, insulation, and circuit protection.

- Fire safety: This involves implementing fire prevention and suppression measures, including fire alarms, sprinklers, and training for fire emergencies.

4. What are the challenges involved in sinking shafts in difficult ground conditions?

- Weak or fractured rock: This can make it difficult to maintain ground control and requires special measures such as grouting, rock bolting, and shotcrete.

- High groundwater levels: This can lead to flooding and requires dewatering measures such as pumping or freezing.

- Presence of hazardous gases: Some ground conditions may contain gases such as methane or hydrogen sulfide, which require special ventilation and safety measures.

- Extreme temperatures: Sinking shafts in areas with extreme temperatures can require special measures for cooling or heating.

5. What are the latest technologies and innovations in shaft sinking?

- Advanced drilling and blasting techniques: These include using computer-controlled drilling and blasting systems for increased accuracy and efficiency.

- Tunnel boring machines (TBMs): TBMs are becoming increasingly popular for sinking shafts due to their ability to excavate and line the shaft simultaneously.

- Autonomous and robotic systems: These systems are being developed to automate tasks such as drilling, bolting, and lining installation, improving safety and efficiency.

- Virtual reality and augmented reality (VR/AR): VR/AR technologies are being used for training, planning, and visualization of shaft sinking operations.

6. What are the environmental considerations in shaft sinking?

- Dust and noise pollution: Shaft sinking operations can generate significant dust and noise, which need to be controlled to minimize impacts on the surrounding environment.

- Water management: Dewatering and groundwater management are important considerations to prevent contamination and protect water resources.

- Waste management: Shaft sinking generates waste materials such as rock cuttings and drilling fluids, which need to be disposed of properly.

- Land use and restoration: Shaft sinking can impact land use, and restoration efforts may be required to minimize ecological impacts.

7. What is your experience in managing a team of shaft sinkers?

In my previous role as a Shaft Sinker Supervisor, I was responsible for managing a team of 10 shaft sinkers. My responsibilities included:

- Planning and organizing work schedules

- Assigning tasks and monitoring progress

- Ensuring compliance with safety regulations

- Conducting training and development

- Motivating and supporting the team

8. What is your understanding of the role of a Shaft Sinker?

A Shaft Sinker is responsible for excavating and lining shafts for mining, construction, and other purposes. The role involves:

- Operating drilling and blasting equipment

- Installing ground support systems such as rock bolts and shotcrete

- Installing shaft linings such as concrete or steel

- Maintaining and repairing shafts

- Ensuring compliance with safety regulations

9. What are the key skills and qualities required to be a successful Shaft Sinker?

- Physical strength and endurance

- Ability to work in confined spaces

- Knowledge of drilling and blasting techniques

- Understanding of ground support systems

- Experience in shaft lining installation

- Attention to safety

- Teamwork and communication skills

10. Why are you interested in this Shaft Sinker position?

I am interested in this Shaft Sinker position because it aligns with my skills and experience in shaft sinking operations. I am confident that I can make a significant contribution to your team with my knowledge of drilling and blasting, ground support systems, and shaft lining installation. I am also an experienced team leader with a strong commitment to safety and quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shaft Sinker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shaft Sinker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Shaft Sinkers are responsible for the construction and maintenance of mine shafts, tunnels, and other underground structures. Their primary responsibilities include:1. Shaft Construction

- Operate drilling equipment to create vertical or inclined shafts in the earth.

- Install shaft linings, such as concrete or steel, to support the shaft walls.

- Ensure the safety and stability of shafts during construction.

2. Tunnel Excavation

- Use excavation methods, such as blasting, tunneling machines, or hand tools, to create tunnels through rock or soil.

- Install tunnel supports, such as rock bolts, wire mesh, or shotcrete, to stabilize the tunnel.

- Maintain and repair tunnels to ensure their functionality and safety.

3. Underground Structural Maintenance

- Inspect and assess the condition of shafts, tunnels, and other underground structures.

- Perform maintenance tasks, such as repairing cracks, replacing supports, and clearing debris.

- Monitor ground conditions and implement measures to prevent collapse or other hazards.

4. Safety and Compliance

- Adhere to safety regulations and procedures to ensure the safety of themselves and others.

- Monitor and control hazards, such as methane gas, dust, and rockfalls.

- Respond to emergencies and implement safety measures to protect workers and the underground environment.

Interview Tips

To ace the interview for a Shaft Sinker position, candidates should:1. Research the Company and Industry

- Learn about the company’s history, operations, and safety record.

- Understand the mining industry, including current trends and technologies.

2. Highlight Relevant Skills and Experience

- Emphasize previous experience in shaft sinking, tunnel excavation, or underground construction.

- Showcase skills in drilling, blasting, excavation, and structural support.

- Quantify accomplishments and provide specific examples to demonstrate your abilities.

3. Demonstrate Safety Knowledge and Commitment

- Explain your understanding of safety regulations and procedures.

- Describe your experience in hazard identification, risk assessment, and emergency response.

- Emphasize your commitment to maintaining a safe work environment.

4. Prepare for Technical Questions

- Expect questions about drilling techniques, excavation methods, and shaft support systems.

- Be prepared to discuss best practices and industry standards related to shaft sinking and tunnel construction.

- Practice solving technical problems or scenarios that may arise on the job.

5. Dress Professionally and Arrive Punctually

- Demonstrate a professional demeanor by dressing appropriately for the interview.

- Arrive on time to show respect for the interviewer and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Shaft Sinker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!