Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Shaker Plate Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Shaker Plate Operator so you can tailor your answers to impress potential employers.

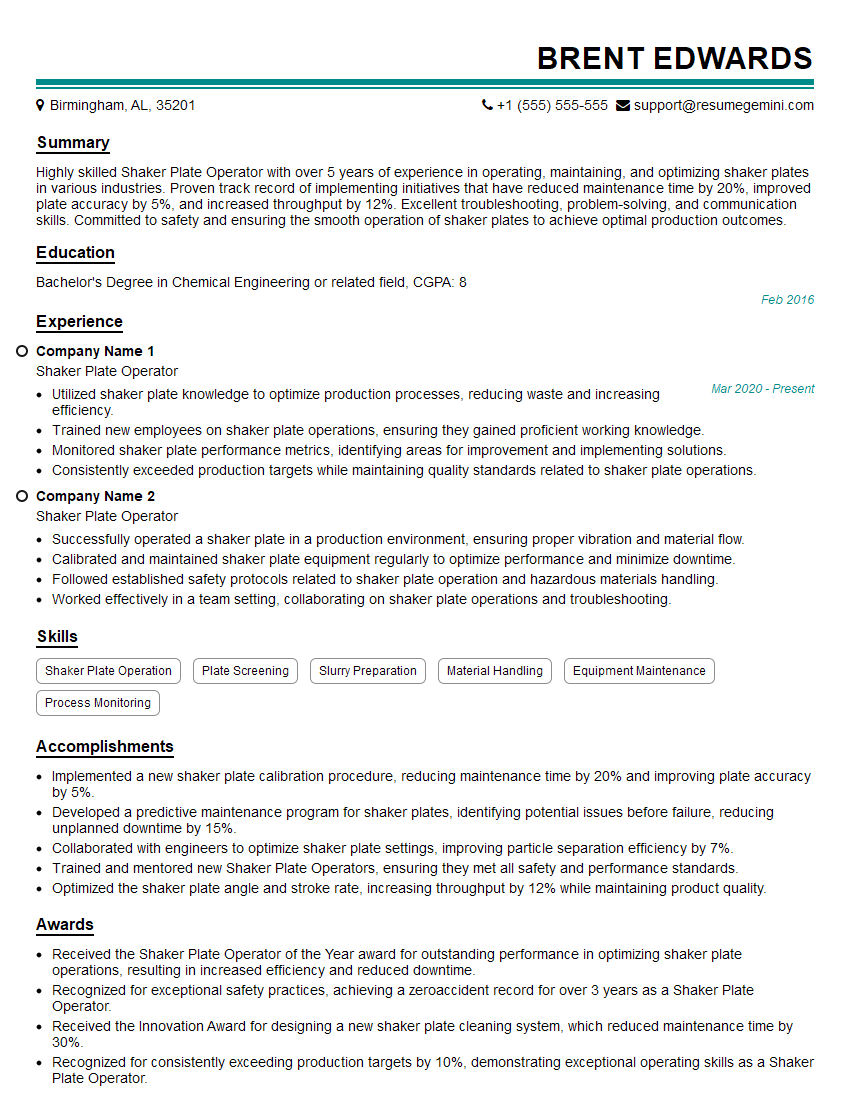

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shaker Plate Operator

1. Explain the process of preparing the shaker plate for operation?

To prepare the shaker plate for operation, I follow these steps:

- Inspect the shaker plate and its components for any damage or wear.

- Clean the shaker plate and screen to remove any debris or residue.

- Install the appropriate screen size for the material to be processed.

- Lubricate all moving parts of the shaker plate according to the manufacturer’s instructions.

- Align the shaker plate with the feed conveyor and discharge chute.

- Ensure that all electrical connections are secure and the shaker plate is properly grounded.

2. How do you calibrate a shaker plate?

Calibration Procedure

- Set up the shaker plate on a stable surface.

- Attach a known weight to the shaker plate.

- Start the shaker plate and adjust the speed until the weight vibrates at the desired amplitude.

- Record the speed and amplitude settings.

- Repeat the process with different weights to create a calibration curve.

Use of Calibration Curve

- Once the calibration curve is created, I can use it to set the shaker plate to the desired amplitude for any given weight.

- This ensures that the shaker plate is vibrating at the correct frequency and amplitude for the material being processed.

3. How do you troubleshoot a shaker plate that is not vibrating properly?

When troubleshooting a shaker plate that is not vibrating properly, I would follow these steps:

- Check if the shaker plate is receiving power.

- Inspect the power cord and electrical connections for any damage.

- Ensure that the shaker plate is properly grounded.

- Check the motor and bearings for any signs of wear or damage.

- Inspect the eccentric weights and springs for any damage or misalignment.

- Clean any debris or foreign objects from the shaker plate and its components.

4. What are the different types of materials that can be processed on a shaker plate?

A variety of materials can be processed on a shaker plate, including:

- Minerals and ores

- Coal and coke

- Sand and gravel

- Chemicals and pharmaceuticals

- Food and beverages

- Agricultural products

5. What are the safety precautions that should be taken when operating a shaker plate?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Ensure that the shaker plate is properly grounded to prevent electrical shock.

- Do not operate the shaker plate in a wet or hazardous environment.

- Keep hands and loose clothing away from moving parts.

- Be aware of the potential for vibration and noise during operation.

- Follow all manufacturer’s operating instructions and safety guidelines.

6. What is the purpose of the eccentric weights on a shaker plate?

- Eccentric weights are used to create the vibration that shakes the material on the shaker plate.

- By adjusting the position and weight of the eccentric weights, I can control the amplitude and frequency of the vibration.

- This allows me to optimize the shaker plate’s performance for the specific material being processed.

7. How do you maintain a shaker plate to ensure optimal performance?

- Regularly inspect the shaker plate for any signs of wear or damage.

- Lubricate all moving parts according to the manufacturer’s instructions.

- Clean the shaker plate and screen to remove any debris or residue.

- Check the alignment of the shaker plate with the feed conveyor and discharge chute.

- Calibrate the shaker plate regularly to ensure accurate vibration settings.

8. What are the different types of screens that can be used on a shaker plate?

- There are various types of screens available for shaker plates, including:

- Wire mesh screens

- Woven wire screens

- Perforated plate screens

- Polyurethane screens

- Rubber screens

- The choice of screen depends on the specific material being processed and the desired separation results.

9. How do you determine the appropriate screen size for a given material?

To determine the appropriate screen size for a given material, I consider the following factors:

- The size and shape of the material particles

- The desired separation efficiency

- The capacity of the shaker plate

- The type of screen material

- By carefully selecting the screen size, I can optimize the shaker plate’s performance and achieve the desired separation results.

10. What are the advantages of using a shaker plate over other separation methods?

- Shaker plates offer several advantages over other separation methods, including:

- High efficiency in separating materials based on size or shape

- Continuous operation, allowing for high throughput rates

- Ability to process a wide range of materials

- Adjustable vibration settings to optimize performance

- Relatively low maintenance requirements

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shaker Plate Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shaker Plate Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Shaker Plate Operators play a crucial role in the mining industry, overseeing the operation of shaker plates that separate valuable minerals from waste. Their primary responsibilities encompass:

1. Shaker Plate Operation

Expertly operating shaker plates to separate desired minerals from waste rocks and materials.

2. Monitoring Process Parameters

Continuously monitoring and adjusting plate speed, stroke, and other parameters to optimize separation efficiency.

3. Equipment Maintenance

Performing routine maintenance and repairs on shaker plates and associated equipment to ensure optimal performance.

4. Troubleshooting

Identifying and resolving issues that arise during shaker plate operation, ensuring smooth and efficient processing.

5. Safety Compliance

Adhering to safety regulations and guidelines to maintain a safe and hazardous-free work environment.

Interview Tips

Preparing thoroughly for a Shaker Plate Operator interview is essential to showcase your skills and increase your chances of success. Here are some practical tips to help you ace the interview:

1. Research the Company and Position

Delve into the company’s background, industry reputation, and specific requirements for the Shaker Plate Operator role.

2. Highlight Relevant Skills and Experience

Emphasize your technical proficiency in operating shaker plates and demonstrate your knowledge of mineral separation processes.

3. Prepare for Common Interview Questions

Anticipate questions related to your experience, technical skills, problem-solving abilities, and commitment to safety.

4. Practice Mock Interviews

Engage in practice interviews to refine your responses, articulate your strengths, and build confidence.

5. Ask Thoughtful Questions

Demonstrate your interest and engagement by asking insightful questions about the company, the role, and the industry.

6. Dress Professionally

First impressions matter, so dress appropriately for the interview to convey a sense of professionalism and respect.

7. Be Enthusiastic and Positive

Display enthusiasm for the role and the company, highlighting your passion for the mining industry and your eagerness to contribute.

Example Outline:

Question: Describe your experience in operating shaker plates.

- Answer: Discuss your involvement in shaker plate operation, mentioning specific responsibilities and achievements.

Question: How do you handle troubleshooting challenges during shaker plate operation?

- Answer: Explain your problem-solving approach, providing examples of how you have identified and resolved issues.

Question: What safety measures do you prioritize as a Shaker Plate Operator?

- Answer: Highlight your adherence to safety protocols, emphasizing your commitment to maintaining a safe work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Shaker Plate Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!