Are you gearing up for an interview for a Shaper Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Shaper Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

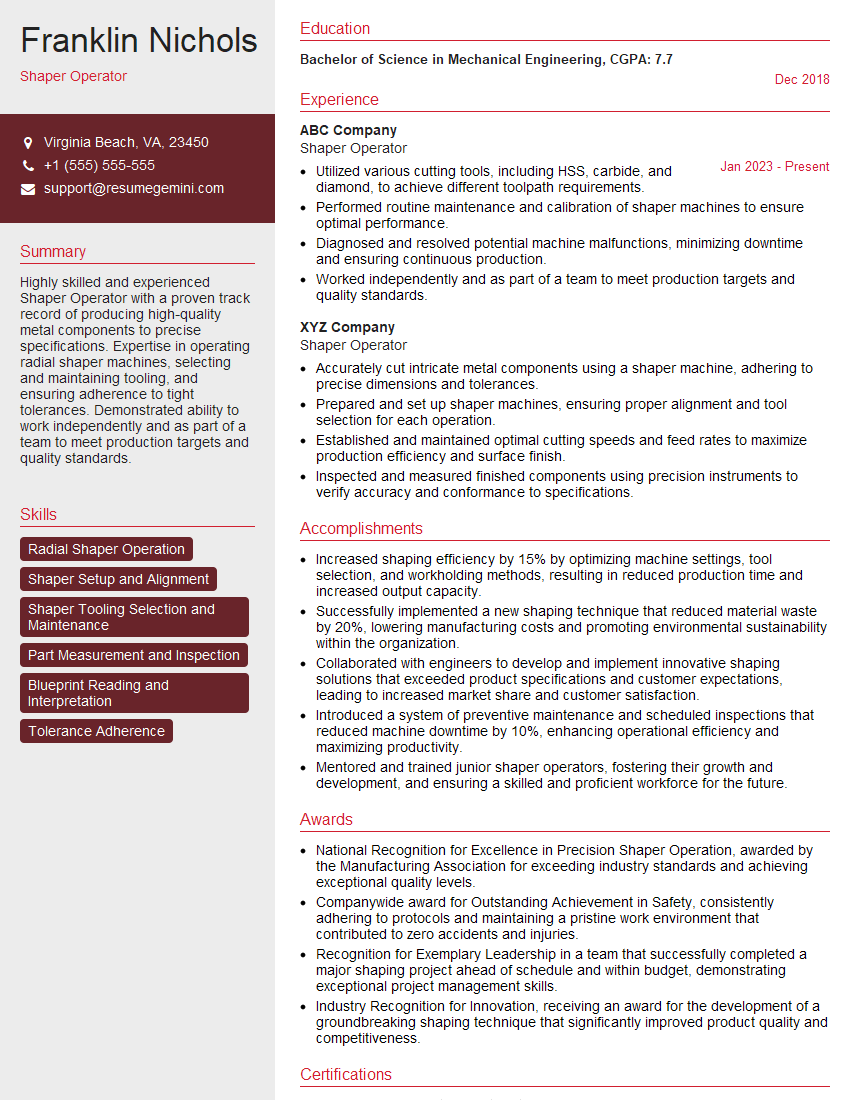

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shaper Operator

1. Describe the process of setting up a shaper machine for a specific job.

The process of setting up a shaper machine for a specific job involves several steps:

- Select the appropriate cutter: The type of cutter used depends on the material being shaped and the desired shape.

- Mount the cutter: The cutter is mounted in the spindle of the shaper machine, ensuring it is securely fastened.

- Adjust the stroke length: The stroke length determines the length of the cut made by the cutter.

- Set the speed: The speed of the machine is adjusted based on the material being shaped.

- Position the workpiece: The workpiece is placed on the table of the shaper machine and positioned correctly relative to the cutter.

- Secure the workpiece: The workpiece is securely clamped or held in place to prevent movement during cutting.

2. What are the different types of shaper cutters, and when should each type be used?

Vertical Cutters

- Used for cutting flat surfaces, slots, and grooves.

Horizontal Cutters

- Used for shaping external surfaces, such as gears, cams, and profiles.

Angular Cutters

- Used for cutting angled surfaces, such as bevels and chamfers.

Form Cutters

- Used for cutting specific shapes, such as letters or intricate designs.

3. How do you ensure the accuracy of the cuts made on a shaper machine?

Ensuring the accuracy of cuts made on a shaper machine involves several techniques:

- Proper machine setup: The machine must be properly leveled, aligned, and calibrated.

- Precise measurements: The workpiece and cutter dimensions must be accurately measured and set.

- Sharp cutters: Dull cutters can produce inaccurate or rough cuts.

- Steady workpiece: The workpiece must be securely held in place to prevent movement.

- Proper cutting speed and feed rate: These factors affect the quality and accuracy of the cut.

4. What safety precautions should be taken when operating a shaper machine?

Operating a shaper machine requires strict adherence to safety precautions:

- Wear appropriate safety gear: Eye protection, gloves, and proper clothing.

- Keep the work area clean and organized: Clear away chips and debris to prevent slips.

- Inspect the machine before use: Check for any damage or loose parts.

- Never reach over or under the rotating cutter: Always use appropriate tools to handle workpieces.

- Securely clamp the workpiece: Loose workpieces can be hazardous.

- Use sharp cutters: Dull cutters can increase the risk of accidents.

- Be aware of the cutter’s path: Ensure that there are no obstructions or hazards in its path.

- Never leave the machine unattended: Always stop the machine and disconnect the power before leaving.

5. Describe a situation where you had to troubleshoot a problem with a shaper machine.

Once, I encountered a problem where the shaper machine was producing inaccurate cuts. After inspecting the machine, I discovered that the cutter was worn and needed to be replaced. I replaced the cutter and recalibrated the machine, which resolved the issue.

6. What is the difference between a shaper machine and a milling machine?

Shaper Machine

- Reciprocating cutting action.

- Suitable for shaping flat surfaces, slots, and grooves.

- Manually operated or CNC-controlled.

Milling Machine

- Rotary cutting action.

- Versatile for various machining operations, including milling, drilling, and boring.

- CNC-controlled for precise and complex operations.

7. How do you maintain a shaper machine to ensure its optimal performance?

Maintaining a shaper machine involves regular cleaning, lubrication, and inspections:

- Cleaning: Remove chips, shavings, and debris from the machine thoroughly.

- Lubrication: Lubricate all moving parts, including gears and bearings, as per the manufacturer’s instructions.

- Inspections: Regularly inspect the machine for any damage, wear, or loose components. Tighten screws, replace worn parts, and repair any faults promptly.

8. What are the different types of materials that can be shaped using a shaper machine?

Shaper machines can be used to shape a wide range of materials, including:

- Metals (ferrous and non-ferrous): Mild steel, stainless steel, aluminum, brass

- Plastics: Acrylic, polycarbonate, nylon

- Wood

9. How do you determine the appropriate feed rate for a shaper machine operation?

The appropriate feed rate depends on several factors:

- Material being shaped: Harder materials require slower feed rates.

- Cutter type and size: Larger cutters can handle higher feed rates.

- Desired surface finish: Slower feed rates produce smoother finishes.

- Machine condition: Well-maintained machines can handle higher feed rates.

10. What are the advantages of using a CNC-controlled shaper machine over a manually operated one?

CNC-Controlled Shaper Machine

- Increased precision: CNC controls ensure accurate and consistent cuts.

- Reduced setup time: Programs can be stored and recalled, minimizing setup time.

- Complex shapes: CNC machines can create complex shapes with ease.

- Improved productivity: Automated operation increases efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shaper Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shaper Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Shaper Operator

Shaper Operators are responsible for operating and maintaining shaping machines used in the manufacturing industry, particularly in metalworking and woodworking.

1. Machine Operation and Maintenance

Operate shaping machines to shape metal or wood components according to specifications using various cutting tools and jigs.

- Set up and adjust shaping machines, including selecting and installing the appropriate cutting tools and fixtures.

- Monitor machine operation, checking for proper cutting parameters and making adjustments as needed.

2. Component Measurement and Inspection

Measure and inspect shaped components to ensure they meet specifications using precision measuring instruments.

- Use calipers, micrometers, and other measuring tools to verify dimensions and tolerances.

- Conduct visual inspections to identify defects or imperfections.

3. Tool Maintenance and Sharpening

Maintain and sharpen cutting tools to ensure optimal performance and prevent breakage.

- Inspect cutting tools for wear and damage, and replace or repair as necessary.

- Use grinding machines to sharpen cutting tools to maintain their sharp edges.

4. Safety and Compliance

Follow established safety protocols and wear appropriate personal protective equipment (PPE) when operating shaping machines.

- Ensure the machine is properly guarded and maintained to prevent accidents.

- Adhere to company safety policies and regulations.

Interview Tips for Shaper Operator Candidates

To ace a Shaper Operator interview, candidates can follow these tips:

1. Research the Company and Position

Learn about the company’s industry, products or services, and its culture.

- Review the job description thoroughly and identify the key responsibilities and qualifications.

- Research the specific shaping machines used in the company’s operations.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in shaper operation, measurement, and inspection techniques.

- Provide specific examples of your ability to shape components to precise specifications.

- Showcase your knowledge of tool maintenance and sharpening.

3. Demonstrate Safety Awareness

Stress your commitment to workplace safety and your understanding of shaping machine hazards.

- Explain your experience in following safety protocols and wearing appropriate PPE.

- Discuss any safety measures you have implemented in previous roles.

4. Prepare for Technical Questions

Expect questions about shaper operation, tool maintenance, and measurement techniques.

- Review basic shaping principles, such as cutting speeds, feeds, and depths of cut.

- Practice setting up and adjusting shaping machines.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Shaper Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.