Are you gearing up for a career in Shaper Set Up Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Shaper Set Up Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

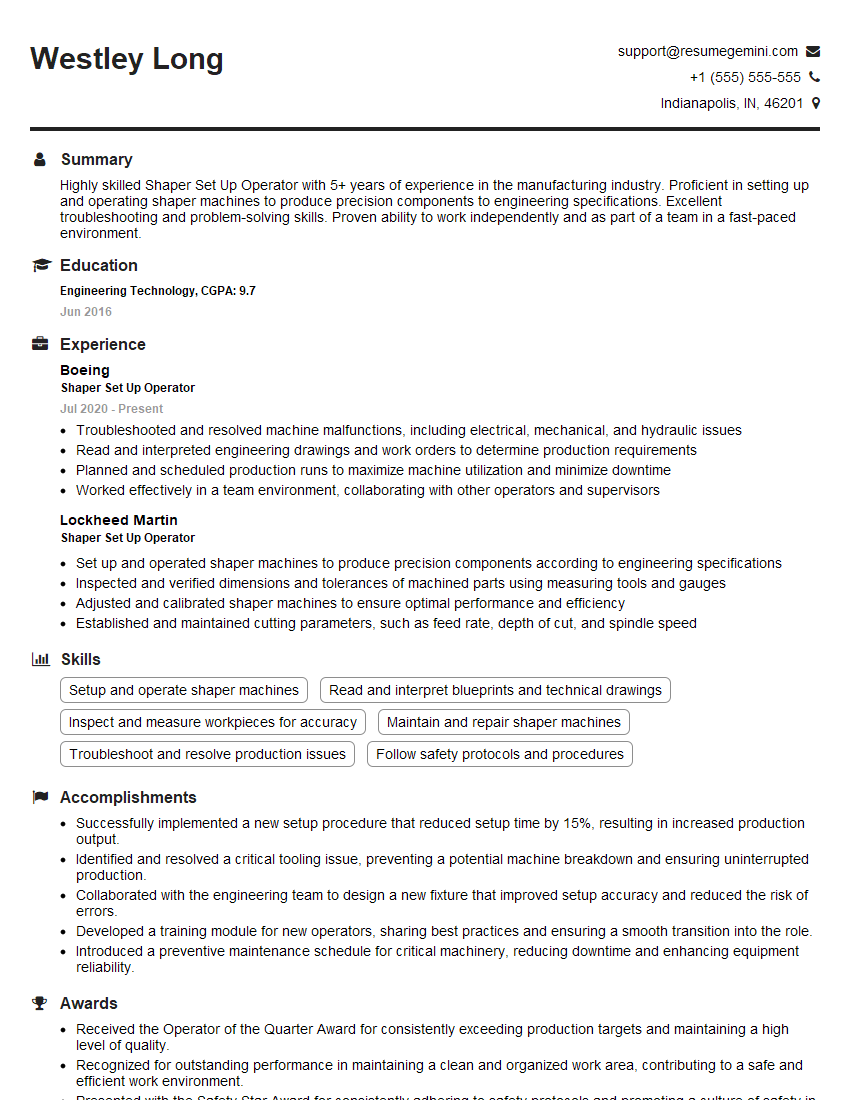

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shaper Set Up Operator

1. What are the key responsibilities of a Shaper Set Up Operator?

The key responsibilities of a Shaper Set Up Operator include:

- Setting up and operating shaping machines to produce precision parts and components.

- Interpreting blueprints and technical drawings to determine the cutting parameters and setup requirements.

- Selecting and installing cutting tools, fixtures, and accessories to ensure efficient and accurate production.

- Monitoring the shaping process, making adjustments as necessary to maintain quality standards.

- Performing routine maintenance and repairs on shaping machines to ensure optimal performance.

2. How do you ensure the accuracy of shaped parts?

- Utilizing precision measuring tools, such as calipers, micrometers, and dial indicators, to check dimensions throughout the shaping process.

- Regularly calibrating the shaping machine and cutting tools to maintain accuracy and prevent errors.

- Paying close attention to the cutting parameters and making adjustments as needed to achieve the desired tolerance specifications.

- Performing quality checks on finished parts to identify and correct any deviations from the required dimensions.

3. What types of materials can you shape using the shaper machine?

The types of materials that can be shaped using the shaper machine include:

- Metals: Steel, stainless steel, aluminum, brass, copper

- Plastics: Acrylic, polycarbonate, polyethylene, polypropylene

- Wood: Hardwoods, softwoods, plywood, MDF

- Composite materials: Fiberglass, carbon fiber, ceramics

4. How do you handle complex setups on the shaping machine?

- Thoroughly studying the blueprints and technical drawings to understand the intricacies of the setup.

- Selecting the appropriate cutting tools, fixtures, and accessories to achieve the desired shape and precision.

- Using specialized techniques, such as compound angles and multiple setups, to create complex contours and profiles.

- Measuring and checking dimensions at every stage of the setup to ensure accuracy.

5. What is the importance of proper tool selection in shaping operations?

- Selecting the correct cutting tools ensures maximum efficiency and accuracy during the shaping process.

- Using the appropriate tool material, geometry, and cutting speed helps optimize performance and produce high-quality parts.

- Proper tool selection reduces wear and tear on the machine and cutting tools, extending their lifespan.

- Matching the tool to the material being shaped prevents damage to both the tool and the workpiece.

6. How do you troubleshoot common problems that occur during shaping operations?

- Identifying the root cause of the problem by observing the symptoms and analyzing the setup.

- Checking the cutting tool for wear, damage, or improper installation.

- Inspecting the workpiece for defects, such as burrs or uneven surfaces.

- Examining the machine for any mechanical issues or misalignment.

- Consulting technical manuals or seeking guidance from experienced colleagues.

7. How do you ensure safety while operating shaping machines?

- Wearing appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Keeping the work area clean and organized to prevent tripping hazards.

- Inspecting the machine and tools regularly to identify potential hazards.

- Following lockout/tagout procedures when performing maintenance or repairs.

- Understanding the machine’s operating instructions and limitations.

8. What is your approach to continuous improvement in your role as a Shaper Set Up Operator?

- Continuously seeking opportunities to optimize setups and improve production efficiency.

- Participating in training programs and workshops to enhance skills and knowledge.

- Suggesting process improvements and implementing them after evaluation.

- Collaborating with colleagues and supervisors to identify areas for improvement.

9. How do you stay updated with the latest technologies and advancements in shaping operations?

- Attending industry conferences and exhibitions to learn about new techniques and equipment.

- Reading trade publications and technical journals to stay informed about industry best practices.

- Engaging in online forums and discussions with other shaping professionals.

- Participating in training programs offered by machine manufacturers and tooling suppliers.

10. What sets you apart as an exceptional Shaper Set Up Operator?

- Strong technical skills, with a deep understanding of shaping machine principles and operations.

- Ability to interpret complex blueprints and technical drawings accurately.

- Exceptional attention to detail and a commitment to producing high-quality parts.

- Proactive problem-solving abilities and a willingness to learn and adapt.

- Excellent communication and teamwork skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shaper Set Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shaper Set Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Shaper Set Up Operators are responsible for setting up, operating, and maintaining shaping machines. Their primary tasks involve:

1. Machine Setup and Operation

Preparing and mounting workpieces onto shaping machines

- Calculating and setting cutting depths, speeds, and feeds

- Positioning and securing fixtures and jigs

2. Quality Control and Inspection

Monitoring the shaping process to ensure product quality

- Checking dimensions and tolerances using measuring instruments

- Identifying and correcting any defects or errors

3. Machine Maintenance and Troubleshooting

Performing routine maintenance on shaping machines

- Inspecting and cleaning moving parts

- Lubricating and adjusting components

- Troubleshoot and resolve machine malfunctions

4. Documentation and Reporting

Maintaining accurate records of shaping operations

- Documenting setup parameters, production data, and machine maintenance

- Reporting any deviations from standard operating procedures

Interview Tips

To ace an interview for a Shaper Set Up Operator position, it’s essential to prepare thoroughly. Here are some interview tips and hacks:

1. Research the Company and Position

Gather information about the company’s products, services, and industry standing. Understand the specific requirements and responsibilities of the Shaper Set Up Operator role.

2. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and knowledge. Practice your answers to highlight your relevant qualifications.

Example Outline:

Tell me about your experience setting up and operating shaping machines.

How do you ensure the accuracy and quality of your work?

What maintenance tasks do you perform on shaping machines?

3. Showcase Your Technical Knowledge

Demonstrate your understanding of shaping machine principles, cutting tools, and materials. Discuss your experience using measuring instruments and quality control techniques.

4. Emphasize Safety and Attention to Detail

Highlight your commitment to safety in the workplace and your meticulous attention to detail. Explain how you ensure the proper operation of shaping machines and prevent accidents.

Example Outline:

Describe your safety protocols when working with shaping machines.

How do you handle situations where there are deviations from standard operating procedures?

5. Prepare Questions for the Interviewer

Asking insightful questions shows your interest in the role and the company. Ask about the company’s growth plans, training opportunities, and industry trends.

Example Questions:

What are the company’s goals for the coming year?

What opportunities are there for professional development?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Shaper Set Up Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!