Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Shaping Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

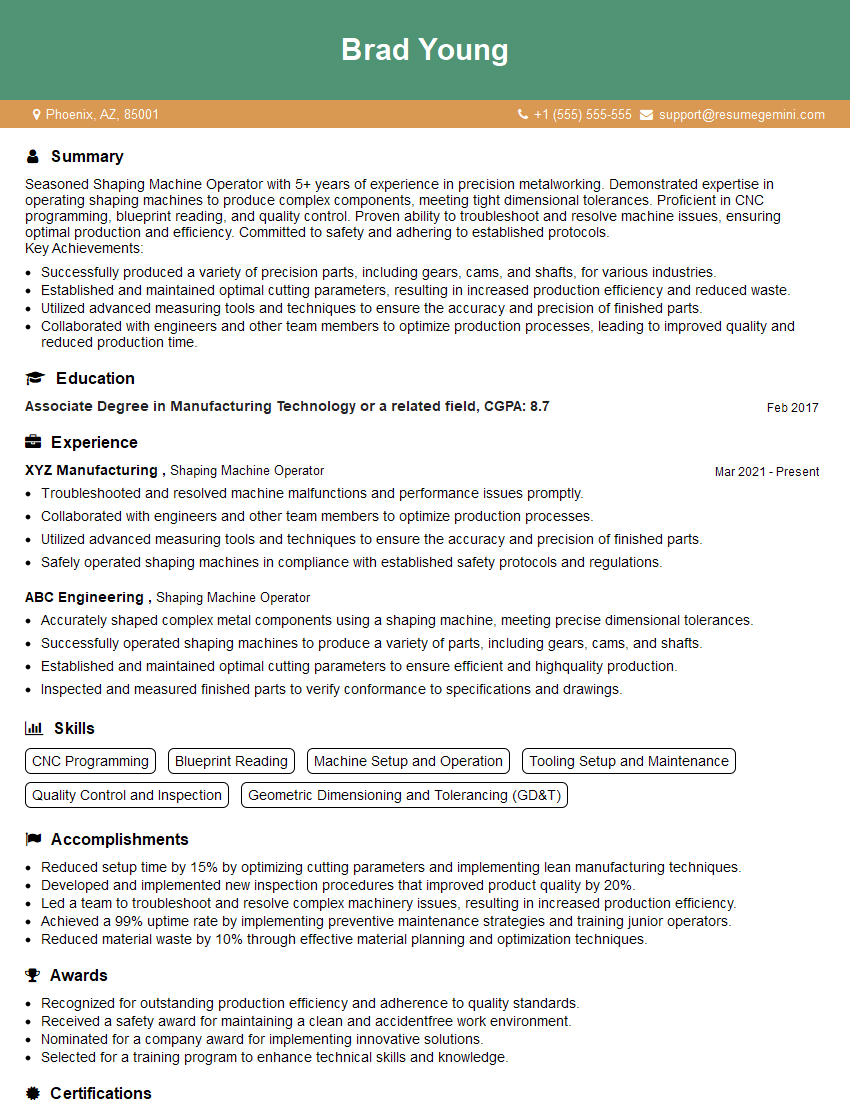

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shaping Machine Operator

1. Describe the different types of shaping machines and their applications?

There are two main types of shaping machines: vertical shaping machines and horizontal shaping machines.

- Vertical shaping machines have the table moving up and down, while the cutting tool moves horizontally. These machines are typically used for shaping flat surfaces.

- Horizontal shaping machines have the table moving horizontally, while the cutting tool moves vertically. These machines are typically used for shaping curved surfaces.

2. What are the main safety considerations when operating a shaping machine?

Personal Protective Equipment (PPE)

- Safety glasses to protect eyes from flying chips

- Safety shoes to protect feet from falling objects

- Gloves to protect hands from cuts and abrasions

Machine Safety

- Ensure proper guarding is in place to prevent contact with moving parts

- Never attempt to clean or adjust the machine while it is running

- Be aware of the location of the emergency stop button

3. How do you set up a shaping machine for a specific job?

- Select the appropriate cutting tool for the material being shaped.

- Install the cutting tool in the tool holder and adjust the tool height.

- Set the spindle speed and feed rate.

- Secure the workpiece to the table.

- Set the table travel limits.

4. What are the different types of cuts that can be made on a shaping machine?

- Straight cuts are made by moving the table back and forth in a straight line.

- Angular cuts are made by moving the table back and forth at an angle.

- Circular cuts are made by moving the table in a circular path.

- Irregular cuts are made by moving the table in a variety of different directions.

5. How do you troubleshoot common problems that can occur when operating a shaping machine?

- Vibration: This can be caused by a loose tool, a worn bearing, or an unbalanced workpiece.

- Chatter: This is a high-pitched noise that can be caused by a dull cutting tool, a loose tool holder, or an improperly set feed rate.

- Overheating: This can be caused by a dull cutting tool, a clogged coolant system, or an excessive feed rate.

6. What are the different types of materials that can be shaped on a shaping machine?

- Metals (e.g., steel, aluminum, brass)

- Plastics

- Wood

- Composites

7. What is the difference between a shaping machine and a milling machine?

- Shaping machines use a single-point cutting tool to remove material by reciprocating it back and forth across the workpiece.

- Milling machines use a rotating cutting tool to remove material by feeding it into the workpiece.

8. What are the advantages of using a shaping machine?

- Versatility: Shaping machines can perform a variety of cuts, including straight cuts, angular cuts, circular cuts, and irregular cuts.

- Accuracy: Shaping machines can produce precision cuts.

- Durability: Shaping machines are built to last and can withstand heavy use.

9. What are the disadvantages of using a shaping machine?

- Relatively slow: Shaping machines are not as fast as some other types of machining equipment.

- Limited capacity: Shaping machines have a limited capacity in terms of the size of the workpieces they can handle.

10. What are the career advancement opportunities for shaping machine operators?

- CNC Programmer: Shaping machine operators who have strong programming skills may be able to advance to CNC programmer positions.

- Supervisor: Shaping machine operators with experience and leadership skills may be able to advance to supervisor positions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shaping Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shaping Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Shaping Machine Operators are responsible for operating shaping machines to cut and shape metal workpieces. Their primary duties include:

1. Setup and Operation

Setting up and operating shaping machines to cut and shape metal workpieces according to blueprints or specifications.

- Interpreting blueprints and technical drawings to determine the required cuts and shapes.

- Selecting and installing appropriate cutting tools and fixtures.

- Adjusting machine settings, such as speed, feed, and depth of cut.

- Monitoring the machine during operation to ensure proper performance and prevent errors.

2. Measurement and Inspection

Measuring and inspecting finished workpieces to ensure they meet specifications.

- Using precision measuring tools, such as calipers and micrometers, to verify dimensions and tolerances.

- Identifying and correcting any deviations from specifications.

- Maintaining records of measurements and inspections.

3. Maintenance and Repair

Performing routine maintenance and minor repairs on shaping machines.

- Cleaning and lubricating machine components.

- Replacing worn or damaged parts.

- Troubleshooting and resolving common machine problems.

4. Safety

Ensuring a safe work environment and adhering to safety protocols.

- Wearing appropriate personal protective equipment, such as safety glasses and gloves.

- Following established safety procedures for machine operation and maintenance.

- Reporting any unsafe conditions or practices to supervisors.

Interview Tips

To ace an interview for a Shaping Machine Operator position, candidates should prepare thoroughly and demonstrate their skills and experience. Here are some tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, industry, and products. Research the specific shaping machine operator position, including the key responsibilities and qualifications.

- Visit the company’s website and social media pages.

- Read industry news and articles.

- Connect with current or former employees on LinkedIn.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the job requirements. Quantify your accomplishments using specific examples and metrics.

- Describe your experience operating shaping machines and the types of materials you have worked with.

- Highlight your ability to read and interpret blueprints and technical drawings.

- Showcase your precision measurement and inspection skills.

3. Prepare for Technical Questions

Be prepared to answer technical questions about shaping machine operation, measurement, and maintenance. Review common shaping machine terminology and troubleshooting techniques.

- Practice answering questions about machine setup, tool selection, and safety procedures.

- Prepare to discuss your experience with different types of cutting tools and materials.

- Demonstrate your understanding of machine maintenance and troubleshooting.

4. Emphasize Safety and Attention to Detail

Shaping Machine Operators must prioritize safety and attention to detail. Highlight your commitment to following safety protocols and ensuring the accuracy of your work.

- Describe your safety practices and knowledge of OSHA regulations.

- Provide examples of how you have maintained a high level of accuracy in your previous roles.

- Explain how you continuously improve your skills and stay up-to-date on industry best practices.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Shaping Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!