Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Shaping Machine Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Shaping Machine Tender so you can tailor your answers to impress potential employers.

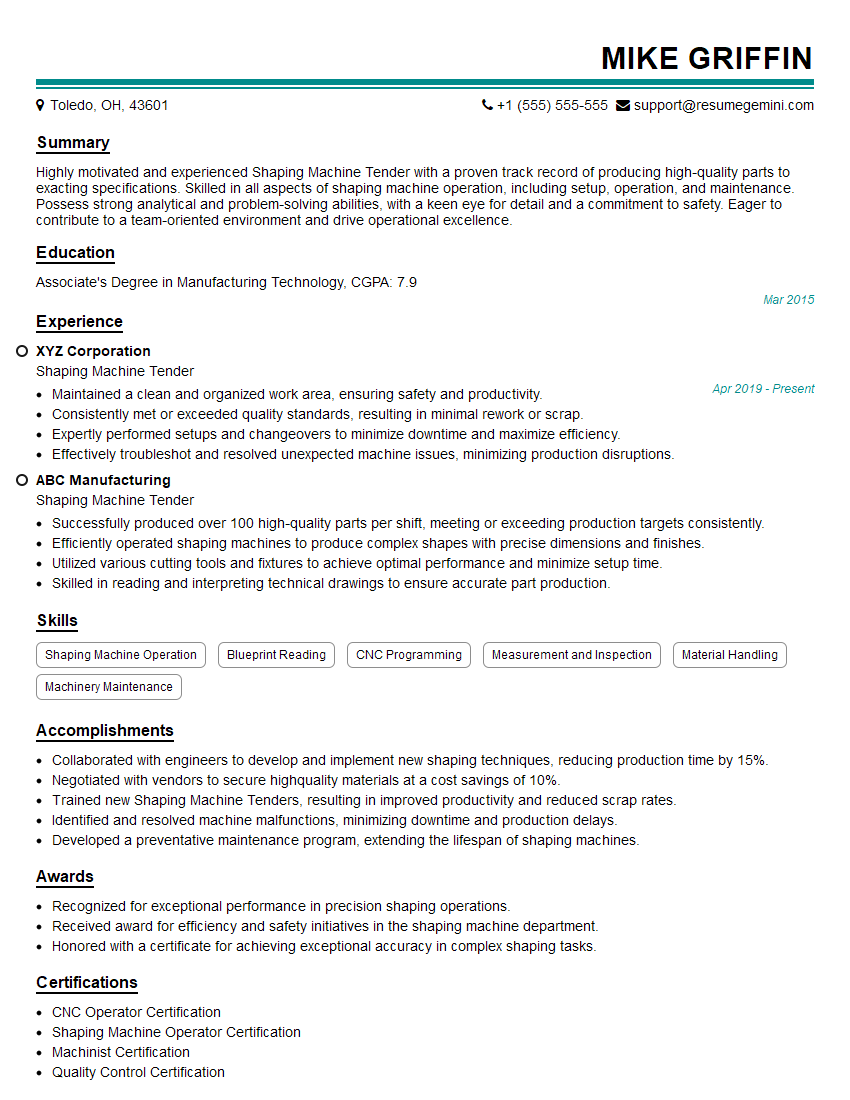

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shaping Machine Tender

1. Explain the process of setting up a shaping machine?

The process of setting up a shaping machine involves the following steps:

- Select the appropriate cutter and arbor for the job.

- Mount the cutter on the arbor and secure it with a collet or drawbar.

- Position the workpiece on the table and secure it with clamps or a vise.

- Set the stroke length and speed of the ram.

- Adjust the toolpost and cutting angle.

- Start the machine and make any necessary adjustments to the feed rate and depth of cut.

2. What are the different types of shaping operations?

Internal Shaping

- Slotting

- Keyway cutting

External Shaping

- Planing

- Milling

3. What are the safety precautions that should be taken when operating a shaping machine?

The following safety precautions should be taken when operating a shaping machine:

- Wear appropriate safety gear, including eye protection, ear protection, and gloves.

- Keep the work area clean and free of debris.

- Inspect the machine before each use and make sure that it is in good working order.

- Secure the workpiece properly before starting the machine.

- Never reach over or around the moving ram.

- Stop the machine immediately if you notice any unusual noises or vibrations.

4. What are the common problems that can occur when operating a shaping machine and how can they be solved?

The following are some common problems that can occur when operating a shaping machine and their solutions:

- Chatter: This can be caused by a dull cutter, incorrect feed rate, or improper workpiece setup. The solution is to sharpen the cutter, adjust the feed rate, or secure the workpiece more securely.

- Overheating: This can be caused by a dull cutter, excessive feed rate, or insufficient lubrication. The solution is to sharpen the cutter, reduce the feed rate, or increase the lubrication.

- Breakage: This can be caused by a defective cutter, incorrect setup, or excessive force. The solution is to replace the cutter, check the setup, or reduce the force.

5. What are the different types of materials that can be shaped using a shaping machine?

The following are some of the different types of materials that can be shaped using a shaping machine:

- Metals

- Plastics

- Wood

- Composites

6. What are the advantages of using a shaping machine over other machining processes?

The following are some of the advantages of using a shaping machine over other machining processes:

- Versatility

- Accuracy

- Durability

- Affordability

7. What are the disadvantages of using a shaping machine?

The following are some of the disadvantages of using a shaping machine:

- Slow speed

- Limited capacity

- Noise

- Requires skilled operator

8. What are the latest developments in shaping machine technology?

The following are some of the latest developments in shaping machine technology:

- CNC shaping machines

- Automatic tool changers

- High-speed spindles

- Advanced cutting tools

9. What are the career opportunities for a shaping machine tender?

The following are some of the career opportunities for a shaping machine tender:

- CNC programmer

- Tool and die maker

- Machinist

- Moldmaker

- Patternmaker

10. What are your strengths and weaknesses as a shaping machine tender?

Some of my strengths as a shaping machine tender include my:

- Attention to detail

- Mechanical aptitude

- Problem-solving skills

- Strong work ethic

Some of my weaknesses as a shaping machine tender include my:

- Lack of experience with CNC shaping machines

- Limited knowledge of advanced cutting tools

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shaping Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shaping Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Shaping machine tenders are responsible for operating and maintaining shaping machines, which are used to shape metal pieces into desired forms. Their key job responsibilities include:

1. Machine Setup and Operation

Setting up the shaping machine according to blueprints and specifications.

- Selecting and installing the appropriate cutting tools.

- Adjusting the machine’s speed, feed, and depth of cut.

- Loading and securing the metal workpiece.

- Starting and monitoring the machine’s operation.

2. Quality Control

Inspecting the finished workpieces to ensure they meet specifications.

- Measuring and verifying dimensions.

- Checking for surface finish and accuracy.

- Making adjustments to the machine or workpiece as needed.

3. Machine Maintenance

Performing routine maintenance on the shaping machine.

- Lubricating and cleaning the machine.

- Inspecting and replacing worn or damaged parts.

- Troubleshooting and resolving machine malfunctions.

4. Work Environment and Safety

Maintaining a clean and safe work environment.

- Wearing appropriate safety gear, such as gloves and eye protection.

- Following established safety procedures.

- Reporting any unsafe conditions or practices.

Interview Tips

To ace an interview for a Shaping Machine Tender position, consider the following tips:

1. Research the Company and Position

Learn about the company’s history, products, and culture. Read the job description carefully to understand the specific requirements and responsibilities.

- Tailor your resume and cover letter to highlight your relevant skills and experience.

- Practice answering common interview questions related to shaping machine operation, quality control, and safety.

2. Prepare for Technical Questions

Be prepared to discuss your understanding of shaping machine principles, such as cutting forces, tool geometry, and workpiece materials.

- Demonstrate your ability to interpret blueprints and technical specifications.

- Explain your experience with different types of cutting tools and their applications.

3. Highlight Your Safety Consciousness

Emphasize your commitment to safety and your knowledge of industry best practices.

- Describe your experience with safety protocols and accident prevention measures.

- Explain how you would identify and mitigate potential hazards in the workplace.

4. Show Your Problem-Solving Skills

Provide examples of how you have handled unexpected situations or challenges while operating a shaping machine.

- Discuss your ability to diagnose and resolve common machine malfunctions.

- Explain how you have used your problem-solving skills to improve productivity or efficiency.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Shaping Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!