Are you gearing up for an interview for a Shear Grinder Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Shear Grinder Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

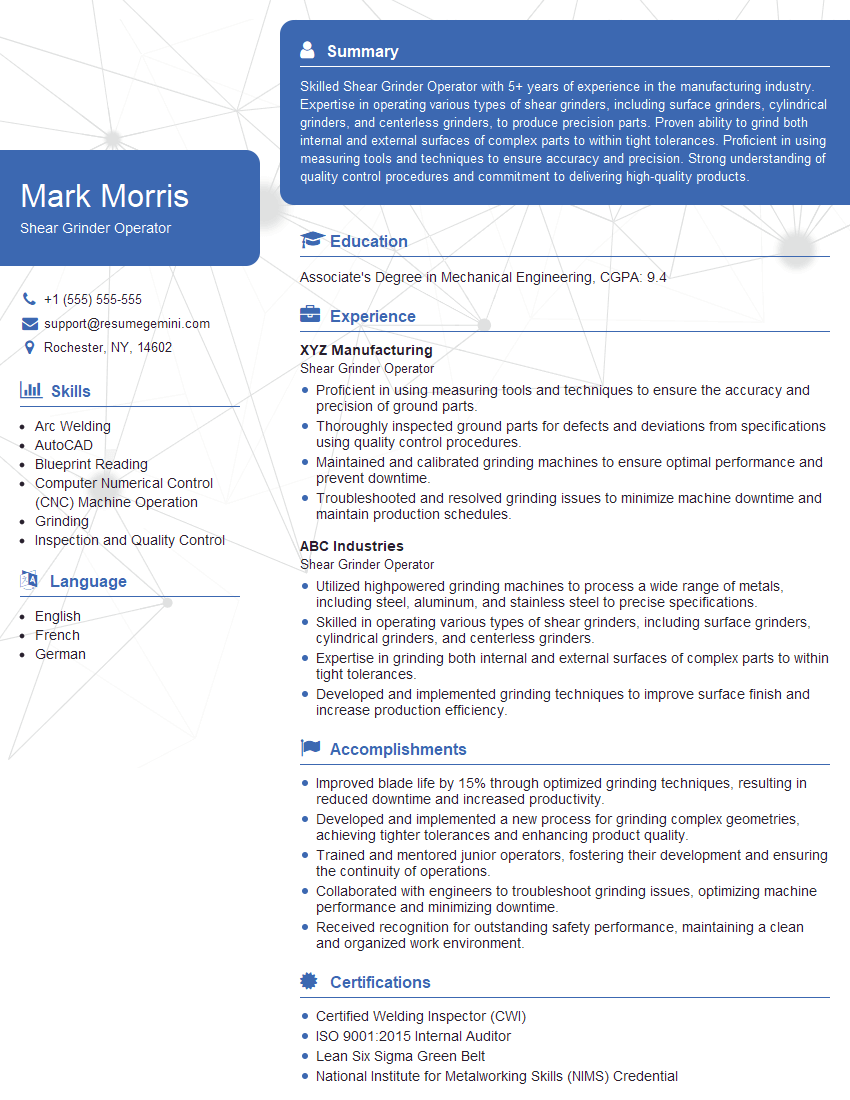

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shear Grinder Operator

1. What are the different types of shear grinders and their applications?

- Straight knife shear grinder: Used for grinding straight knives used in paper, textile, and plastics industries.

- Rotary shear grinder: Used for grinding rotary shears used in metalworking and recycling industries.

- Guillotine shear grinder: Used for grinding guillotine shears used in metalworking and construction industries.

- Angle shear grinder: Used for grinding angle shears used in metalworking and shipbuilding industries.

- CNC shear grinder: Advanced shear grinder controlled by computer numerical control (CNC), offering high precision and accuracy.

2. Describe the process of setting up and operating a shear grinder.

Preparing the shear grinder

- Inspect and clean the shear grinder.

- Install the appropriate grinding wheel for the material being ground.

- Set the grinding depth and angle according to the manufacturer’s specifications.

Operating the shear grinder

- Secure the workpiece in the holding device.

- Start the grinding wheel and move the workpiece across the wheel surface at a steady pace.

- Use coolant or lubricant to prevent overheating and prolong wheel life.

3. How do you maintain and troubleshoot a shear grinder?

- Regularly clean and inspect the shear grinder for any damage or wear.

- Check the grinding wheel for signs of wear or damage and replace it if necessary.

- Lubricate moving parts according to the manufacturer’s recommendations.

- Troubleshoot common issues such as vibration, excessive noise, or grinding wheel breakage by checking for loose bolts, misalignment, or worn components.

- Follow safety guidelines and wear appropriate personal protective equipment (PPE) while performing maintenance and troubleshooting.

4. What safety precautions are essential when operating a shear grinder?

- Wear safety glasses, gloves, and ear protection.

- Ensure the shear grinder is properly grounded to prevent electrical shock.

- Keep the work area clean and free from tripping hazards.

- Never operate the shear grinder without proper training and authorization.

- Use a push stick or other safety device to feed the workpiece into the grinder.

- Inspect the grinding wheel regularly for cracks or damage and replace it immediately if necessary.

5. How do you ensure the accuracy and precision of the grinding process?

- Use precision measuring tools to set the grinding depth and angle.

- Calibrate the shear grinder regularly to maintain accuracy.

- Monitor the grinding process and make adjustments as needed to ensure the desired results.

- Use a variety of grinding wheels with different grit sizes to achieve the required surface finish.

- Follow manufacturer’s recommendations and best practices for grinding specific materials.

6. What are the different types of grinding wheels used for shear grinding and their applications?

- Aluminum oxide wheels: General purpose, suitable for a wide range of materials.

- Silicon carbide wheels: Used for grinding hard materials, such as hardened steels and ceramics.

- Diamond wheels: Used for grinding extremely hard materials, such as tungsten carbide and gemstones.

- CBN wheels: Used for grinding high-speed steels and other difficult-to-machine materials.

- Electroplated wheels: Used for sharpening tools and achieving fine surface finishes.

7. How do you calculate the grinding feed rate and speed for different materials?

- Consider the hardness and toughness of the material being ground.

- Select the appropriate grinding wheel grit size and bond type.

- Use manufacturer’s recommendations or empirical data to determine the grinding feed rate and speed.

- Make adjustments to the feed rate and speed based on the desired surface finish and production requirements.

- Monitor the grinding process and make adjustments as needed to optimize efficiency and quality.

8. What techniques do you use to minimize heat generation and workpiece distortion during shear grinding?

- Use flood coolant or a grinding lubricant to cool the workpiece and grinding wheel.

- Grind in multiple passes with light cuts to reduce heat buildup.

- Use a sharp grinding wheel to minimize friction and wear.

- Support the workpiece properly to prevent deflection and distortion.

- Monitor the grinding process and make adjustments to the feed rate and speed as needed to prevent excessive heat.

9. How do you troubleshoot common shear grinding problems, such as burrs, chatter, or poor surface finish?

Burrs

- Increase the grinding speed.

- Use a finer-grit grinding wheel.

- Reduce the grinding depth.

Chatter

- Check for loose bolts or misalignment in the shear grinder.

- Use a grinding wheel with a coarser grit size.

- Reduce the grinding feed rate.

Poor surface finish

- Use a grinding wheel with a finer grit size.

- Increase the grinding speed.

- Use a dressing tool to condition the grinding wheel.

10. Describe your experience with different shear grinding machines and how you have used them to achieve specific grinding requirements.

Provide examples of the types of shear grinding machines you have operated, the materials you have ground, the grinding techniques you have used, and the results you have achieved.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shear Grinder Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shear Grinder Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Shear Grinder Operators play a vital role in the production process, ensuring the safety and efficiency of shear grinding operations. Their main responsibilities include:

1. Machine Operation

Primarily, Shear Grinder Operators are responsible for operating shear grinding machines to remove excess material from metal components following blanking or stamping processes.

- Setting up and operating shear grinding machines according to specifications

- Monitoring machine performance, identifying potential issues, and taking corrective actions

2. Quality Control and Inspection

To ensure the precision and quality of the finished products, Shear Grinder Operators:

- Inspecting the finished components for defects, such as burrs, scratches, or dimensional inaccuracies

- Measuring and verifying the dimensions of the components against specifications using precision measuring instruments

- Maintaining detailed records of inspection results and reporting any non-conformances

3. Machine Maintenance

Regular maintenance is critical to the smooth functioning of shear grinding machines. Shear Grinder Operators:

- Lubricating, cleaning, and inspecting machines regularly

- Identifying and replacing worn or damaged parts promptly

- Conducting routine maintenance checks according to established procedures

4. Safety

Shear grinding operations involve potential hazards, and safety is paramount. Shear Grinder Operators are responsible for:

- Following all safety protocols and regulations

- Wearing appropriate personal protective equipment

- Maintaining a clean and organized work area

- Reporting any safety concerns or incidents

Interview Tips

To ace the interview for a Shear Grinder Operator position, it is essential to prepare thoroughly and demonstrate your knowledge and skills. Here are some tips to guide your preparation:

1. Research the Company and Role

Familiarize yourself with the company’s background, industry, and specific requirements for the Shear Grinder Operator role. This will help you tailor your answers to match their needs.

- Visit the company’s website and social media pages

- Research the industry and identify any trends or advancements

- Review the job description thoroughly and note the key responsibilities and qualifications

2. Practice Answering Common Interview Questions

There are certain common questions that interviewers often ask in Shear Grinder Operator interviews. Prepare your answers by considering the following points:

- Describe your experience in operating shear grinding machines.

- How do you ensure the quality and precision of your work?

- Talk about your understanding of safety protocols in shear grinding operations.

3. Showcase Your Technical Skills

Highlight your proficiency in using shear grinding machines, measuring instruments, and any other relevant equipment. Provide specific examples of your technical abilities:

- Describe a time when you identified and resolved a machine issue that improved productivity.

- Share an instance where you implemented a process improvement that enhanced the quality of the finished products.

4. Emphasize Your Safety and Attention to Detail

Interviewers seek candidates who prioritize safety and accuracy in shear grinding operations. Emphasize your commitment to following safety protocols and your ability to work with meticulous attention to detail:

- Highlight your knowledge of safety regulations and your experience in maintaining a safe work environment.

- Provide examples of how you have ensured the accuracy and precision of your work, even under pressure.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Shear Grinder Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!