Are you gearing up for a career in Shear Scrapman? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Shear Scrapman and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

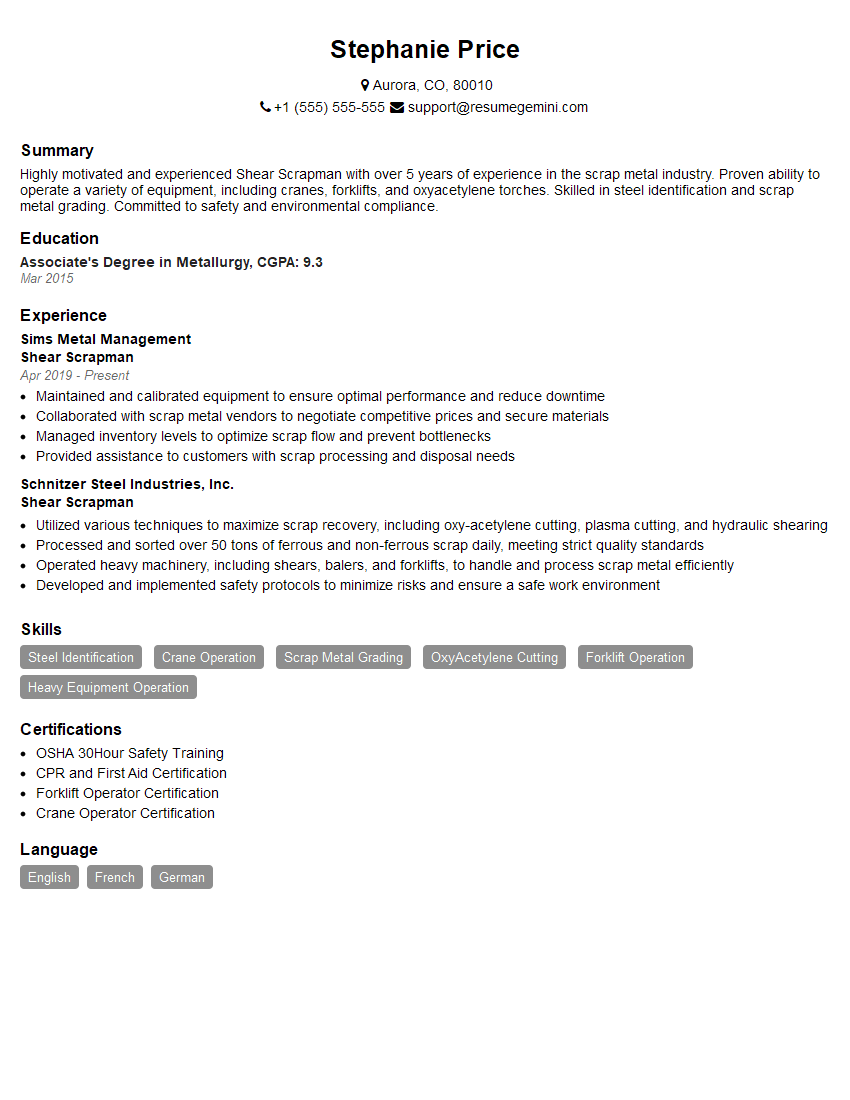

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shear Scrapman

1. What are the different types of shearing machines and how do they differ in terms of their capabilities and applications?

- Mechanical Shears: These shears utilize a mechanical drive system, typically powered by a flywheel or motor, to generate the shearing force. They are known for their high power and durability, making them suitable for heavy-duty applications.

- Hydraulic Shears: Hydraulic shears employ hydraulic cylinders to apply shearing force. They offer precise control over the shearing process and can handle a wide range of materials, including thin metals and intricate shapes.

- Guillotine Shears: Guillotine shears feature a vertically reciprocating blade that descends onto the material, shearing it with a clean and precise cut. They are commonly used in high-volume production environments.

- Rotary Shears: Rotary shears utilize a rotating blade to cut through the material. They are suitable for continuous shearing operations and can handle a wide variety of materials, including plastics, fabrics, and non-ferrous metals.

- Laser Shears: Laser shears employ a high-powered laser beam to cut through the material, resulting in precise and burr-free edges. They are ideal for intricate cuts and working with thin materials.

2. How do you determine the appropriate shear blade for a specific application?

- Consider the material properties, such as its thickness, hardness, and tensile strength.

- Determine the desired cut quality, including the required tolerances and edge finish.

- Select a blade material that is compatible with the material being sheared and provides the necessary durability and longevity.

- Choose the appropriate blade geometry, including the blade angle, clearance, and rake, to optimize cutting performance.

- Verify the blade’s compatibility with the shearing machine and ensure proper alignment and adjustment.

3. What are the common troubleshooting techniques for shearing machines?

- Blade Misalignment: Inspect the blade alignment and adjust it if necessary to ensure proper shearing.

- Dull Blades: Check the blade sharpness and replace or sharpen them to maintain optimal cutting performance.

- Hydraulic System Issues: Diagnose any hydraulic leaks or malfunctions and repair or replace faulty components.

- Electrical Problems: Troubleshoot electrical connections, switches, and sensors to identify and rectify any issues.

- Material Handling Issues: Ensure that the material is properly positioned and supported during the shearing process.

- Insufficient Lubrication: Verify that the machine is adequately lubricated and apply lubricants as recommended by the manufacturer.

4. How do you ensure the safety of operators when working with shearing machines?

- Provide comprehensive safety training to operators, covering proper operating procedures and emergency protocols.

- Implement appropriate machine guarding, such as enclosures, interlocks, and safety sensors, to minimize the risk of injury.

- Enforce the use of personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Establish clear work instructions and ensure that operators follow them diligently.

- Regularly inspect and maintain the machine to keep it in safe operating condition.

5. What are the key maintenance tasks for shearing machines?

- Regular Cleaning: Remove debris, chips, and lubricants from the machine to prevent contamination and ensure smooth operation.

- Blade Inspection and Sharpening: Inspect blades for wear and damage, and sharpen or replace them as needed to maintain optimal cutting performance.

- Lubrication: Lubricate all moving parts and components as per the manufacturer’s recommendations to reduce friction and wear.

- Electrical Maintenance: Inspect electrical connections, wires, and components for damage or loose connections, and repair or replace them if necessary.

- Hydraulic System Maintenance: Monitor hydraulic fluid levels, check for leaks, and replace filters to maintain system integrity.

6. How do you optimize the productivity of shearing operations?

- Proper Material Handling: Ensure efficient loading and unloading of materials to minimize downtime.

- Optimized Blade Selection: Choose the appropriate blade type and geometry for the specific material and application.

- Correct Machine Setup: Set up the machine with the correct cutting parameters, such as blade gap, hold-down pressure, and cutting speed.

- Preventive Maintenance: Regularly maintain the machine to prevent breakdowns and ensure optimal performance.

- Operator Training: Train operators on best practices to maximize efficiency and minimize errors.

7. What are the latest advancements or trends in shearing technology?

- Automation: Integration of automation systems to reduce manual labor, improve accuracy, and increase productivity.

- Laser Shearing: Advanced laser technology for precise and burr-free cutting of complex shapes and thin materials.

- Advanced Blade Materials: Development of new blade materials with enhanced durability, wear resistance, and cutting performance.

- Digital Control Systems: User-friendly digital interfaces and software for precise control over shearing parameters and monitoring machine performance.

- Sustainability: Focus on reducing energy consumption, minimizing waste, and promoting environmentally friendly practices.

8. How do you stay updated with the latest developments in the shearing industry?

- Attend industry conferences, seminars, and exhibitions to learn about new technologies and advancements.

- Read technical journals, articles, and white papers to stay informed about the latest research and best practices.

- Connect with experts, suppliers, and manufacturers in the industry through online forums and social media.

- Participate in training programs and workshops to enhance technical skills and knowledge.

- Seek mentorship or guidance from experienced professionals in the field.

9. How do you handle challenging or complex shearing projects?

- Thorough Analysis: Carefully assess the project requirements, material properties, and machine capabilities.

- Customized Approach: Develop a tailored shearing plan, including blade selection, cutting parameters, and material handling strategies.

- Precision and Accuracy: Utilize advanced techniques and equipment to ensure precise cuts and meet the required tolerances.

- Problem-Solving Mindset: Anticipate potential challenges and develop contingency plans to address them effectively.

- Continuous Improvement: Monitor the shearing process and make adjustments as needed to optimize performance.

10. How do you ensure that your work meets the required quality standards?

- Adherence to Specifications: Meticulously follow the project specifications and maintain the required quality standards.

- Precision and Accuracy: Utilize precise measuring instruments and techniques to ensure dimensional accuracy and consistency.

- Quality Control Checks: Implement rigorous quality control measures throughout the shearing process, including regular inspections and testing.

- Continuous Improvement: Regularly evaluate the shearing process and seek ways to improve quality and efficiency.

- Customer Feedback: Gather customer feedback and use it to identify areas for improvement and enhance overall quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shear Scrapman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shear Scrapman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Shear Scrapmen are responsible for the safe and efficient operation of shear machines to process ferrous and non-ferrous scrap metal for recycling purposes.

1. Machine Operation

Shear Scrapmen operate a range of shear machines used to reduce scrap metal into smaller sizes. They must have a thorough understanding of the machines’ functions, capacities, and safety protocols.

- Set up and calibrate shear machines according to job specifications.

- Position scrap metal for optimal shearing and avoid damage to equipment.

2. Material Handling

Shear Scrapmen handle large quantities of scrap metal, requiring physical strength and dexterity. They must be able to load and unload heavy materials safely and efficiently.

- Operate cranes, forklifts, and other material handling equipment to move scrap metal.

- Inspect scrap metal for contamination and remove any hazardous materials.

3. Quality Control

Shear Scrapmen must adhere to quality standards by ensuring that scrap metal is processed to meet customer specifications. They must check the size, weight, and composition of metal products.

- Inspect sheared metal for defects, ensuring it meets the required specifications.

- Separate and segregate different grades of scrap metal to enhance its value.

4. Safety and Compliance

Shear Scrapmen work in a hazardous environment, so they must prioritize safety compliance. They must wear appropriate personal protective equipment and follow safety procedures.

- Maintain a clean and organized work area to minimize hazards.

- Adhere to all safety regulations and protocols, ensuring the well-being of themselves and others.

Interview Tips

Preparing for a Shear Scrapman interview requires a thorough understanding of the role and industry-specific knowledge. Here are some tips to help you ace your interview:

1. Research the Company and Industry

Familiarize yourself with the company’s website, history, and current projects. Research the scrap metal recycling industry to demonstrate your understanding of the business.

- Look up industry-specific publications and news articles to stay informed about current trends.

- Visit the company’s social media pages to learn about their culture and recent developments.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in operating shear machines, handling heavy materials, and ensuring quality control. Share examples of your ability to work in a fast-paced and physically demanding environment.

- Quantify your accomplishments with specific metrics, such as the amount of scrap metal processed or the percentage of defects reduced.

- If you have experience in a similar role, highlight your transferable skills and knowledge.

3. Demonstrate Safety Awareness

Safety is paramount in this role. Express your commitment to following safety protocols, wearing proper PPE, and maintaining a safe work environment. Share any safety certifications or training you have completed.

- Emphasize your ability to identify potential hazards and take appropriate preventive measures.

- Explain your understanding of the importance of adhering to industry safety standards.

4. Prepare for Physical Tasks

Shear Scrapmen perform physically demanding tasks. Be prepared to discuss your physical abilities, including your strength, stamina, and dexterity. Mention any relevant physical activities or fitness routines you engage in.

- Indicate your willingness to undergo any necessary physical assessments or training programs.

- Express your confidence in your ability to meet the physical demands of the role.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Shear Scrapman role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.