Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Shear Setter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

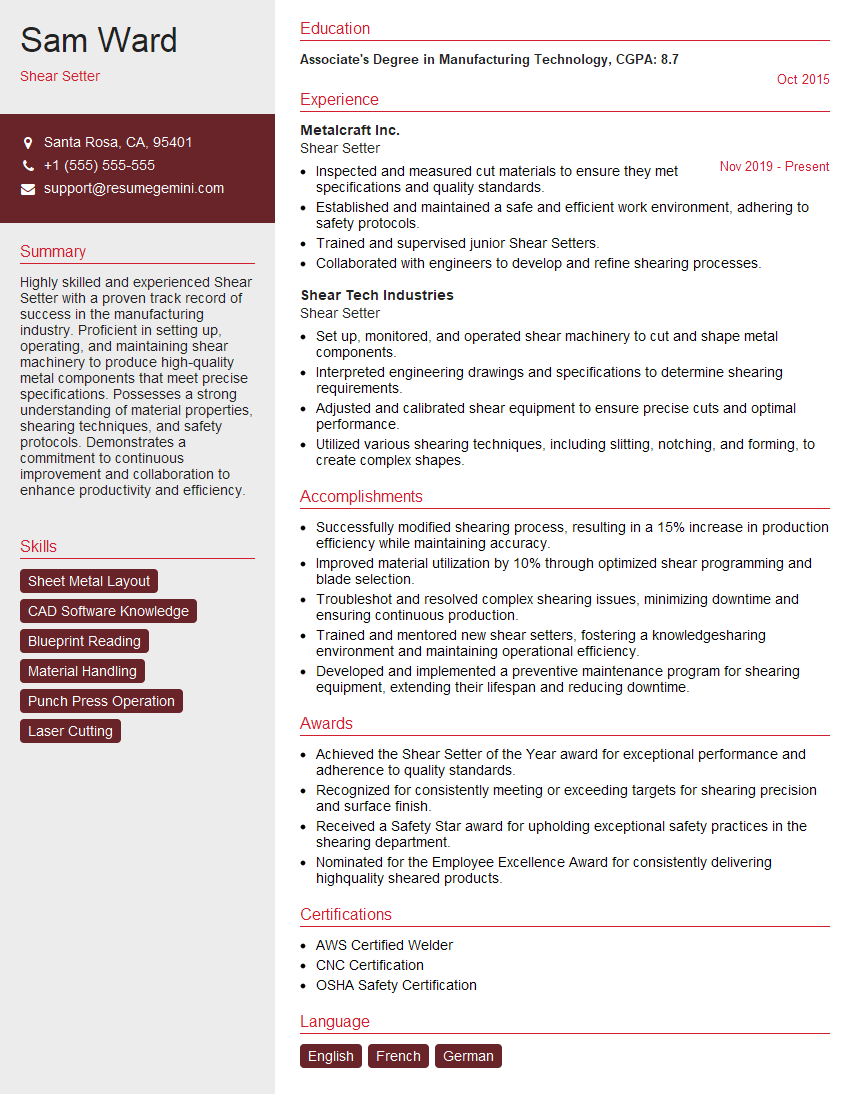

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shear Setter

1. What are the different types of shearing machines used in the industry, and which one is most suitable for a given application?

The most common types of shearing machines used in the industry are alligator shears, guillotine shears, and flying shears. Each type of shearing machine has its own advantages and disadvantages, and the most suitable machine for a given application will depend on the material being cut, the thickness of the material, and the desired cut quality. Alligator shears are best suited for cutting thick, heavy materials, such as steel plate. Guillotine shears are best suited for cutting thinner materials, such as sheet metal. Flying shears are best suited for cutting materials that are moving, such as in a production line.

2. How do you determine the correct blade clearance for a given material?

The correct blade clearance for a shearing machine is determined by the thickness of the material being cut. The blade clearance should be approximately 0.001 inches per inch of material thickness. For example, if you are cutting 1/4-inch thick material, the blade clearance should be 0.004 inches.

Factors that Affect Blade Clearance

- Material thickness

- Material hardness

- Shear strength of the material

- Blade sharpness

3. What are the different types of shearing blades, and which one is most suitable for a given application?

The most common types of shearing blades are straight blades, notched blades, and serrated blades. Straight blades are best suited for cutting thin, soft materials, such as paper and plastic. Notched blades are best suited for cutting thick, tough materials, such as metal and wood. Serrated blades are best suited for cutting materials that are prone to tearing, such as fabric and leather.

4. How do you maintain a shearing machine?

- Keep the machine clean and free of debris.

- Lubricate the machine regularly.

- Inspect the machine for wear and tear.

- Sharpen the blades regularly.

- Calibrate the machine regularly.

5. What are the safety precautions that must be taken when operating a shearing machine?

- Wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Keep your hands away from the moving blades.

- Do not operate the machine if you are fatigued or under the influence of alcohol or drugs.

- Be aware of your surroundings and keep others away from the machine.

6. What are the different types of shearing defects, and how can they be prevented?

- Burrs: Burrs are small, raised edges on the cut surface of the material. They can be prevented by using sharp blades and by setting the blade clearance correctly.

- Distortion: Distortion is a change in the shape of the material after it has been cut. It can be prevented by using a sharp blade and by supporting the material properly during cutting.

- Edge cracking: Edge cracking is a type of defect that occurs when the material cracks along the edge of the cut. It can be prevented by using a sharp blade and by setting the blade clearance correctly.

- Tearing: Tearing is a type of defect that occurs when the material tears instead of being cut. It can be prevented by using a sharp blade and by setting the blade clearance correctly.

7. What are the different types of materials that can be sheared, and what are the special considerations for each type of material?

- Metal: Metal is the most common type of material that is sheared. It is important to use a sharp blade and to set the blade clearance correctly when shearing metal.

- Plastic: Plastic is a relatively soft material that can be sheared easily. It is important to use a sharp blade and to set the blade clearance correctly when shearing plastic.

- Wood: Wood is a hard material that can be difficult to shear. It is important to use a sharp blade and to set the blade clearance correctly when shearing wood.

- Fabric: Fabric is a very soft material that can be easily torn. It is important to use a sharp blade and to set the blade clearance correctly when shearing fabric.

8. What are the different types of finishes that can be achieved with a shearing machine?

- Sheared finish: A sheared finish is the most common type of finish that is achieved with a shearing machine. It is a relatively rough finish that has a lot of burrs.

- Ground finish: A ground finish is a smoother finish than a sheared finish. It is achieved by grinding the cut surface of the material.

- Polished finish: A polished finish is the smoothest finish that can be achieved with a shearing machine. It is achieved by polishing the cut surface of the material.

9. What are the different factors that can affect the cost of shearing?

- Material: The type of material being cut can affect the cost of shearing. Harder materials are more difficult to shear than softer materials.

- Thickness: The thickness of the material being cut can also affect the cost of shearing. Thicker materials are more difficult to shear than thinner materials.

- Quantity: The quantity of material being cut can also affect the cost of shearing. Larger quantities can be sheared more efficiently than smaller quantities.

- Equipment: The type of equipment used can also affect the cost of shearing. More expensive equipment can produce higher quality cuts than less expensive equipment.

10. What are the different applications for shearing?

- Cutting metal: Shearing is commonly used to cut metal in a variety of applications, such as automotive manufacturing, shipbuilding, and construction.

- Cutting plastic: Shearing is also used to cut plastic in a variety of applications, such as packaging and manufacturing.

- Cutting wood: Shearing is sometimes used to cut wood, such as in the manufacture of furniture and cabinetry.

- Cutting fabric: Shearing is also used to cut fabric, such as in the manufacture of clothing and textiles.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shear Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shear Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Shear Setters play a crucial role in the manufacturing industry, operating and maintaining shear machines used to cut metal sheets into desired shapes and sizes. Their key job responsibilities include:

1. Machine Setup and Operation

Preparing the shear machine by selecting and installing appropriate blades, adjusting cutting clearances, and verifying machine settings.

- Monitoring machine operation, ensuring smooth and efficient cutting.

- Optimizing cutting parameters to achieve required precision and quality standards.

2. Material Handling

Loading and unloading metal sheets onto the shear machine, using proper material handling techniques.

- Inspecting incoming materials for defects and ensuring they meet specifications.

- Adjusting machine settings based on material thickness and type.

3. Quality Control

Measuring and inspecting cut parts to ensure they meet dimensional accuracy and quality requirements.

- Maintaining records of cut parts and identifying any quality issues.

- Working with quality control personnel to ensure adherence to established standards.

4. Maintenance and Troubleshooting

Performing regular maintenance tasks, such as cleaning, lubricating, and adjusting the shear machine.

- Identifying and resolving minor machine malfunctions and reporting major issues to maintenance personnel.

- Maintaining a clean and organized work area to ensure safety and efficiency.

Interview Tips

To ace an interview for a Shear Setter position, candidates should prepare themselves thoroughly and demonstrate their knowledge, skills, and experience. Here are some key tips:

1. Understand the Role

Familiarize yourself with the job description and make sure you understand the key responsibilities, skills, and qualifications required for the role.

- Research the company and the specific industry to gain insights into their operations and requirements.

- Practice answering common interview questions related to the role, highlighting your relevant experience and abilities.

2. Highlight Relevant Experience

Emphasize your experience in operating and maintaining shear machines, as well as your knowledge of cutting processes and quality standards.

- Provide specific examples of your work and quantify your accomplishments whenever possible.

- Discuss any training or certifications you have obtained in shear machine operation.

3. Demonstrate Attention to Detail

Shear Setters must have a keen eye for detail and accuracy. Highlight your ability to ensure precise cuts, meet quality specifications, and identify any potential issues.

- Describe your approach to ensuring accuracy and consistency in your work.

- Mention any quality control measures you have implemented or participated in.

4. Emphasize Safety

Safety is paramount in manufacturing environments. Emphasize your commitment to following safety protocols and procedures.

- Discuss your experience with safety regulations and your adherence to best practices.

- Mention any safety initiatives or improvements you have implemented or participated in.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Shear Setter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.