Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Shear Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

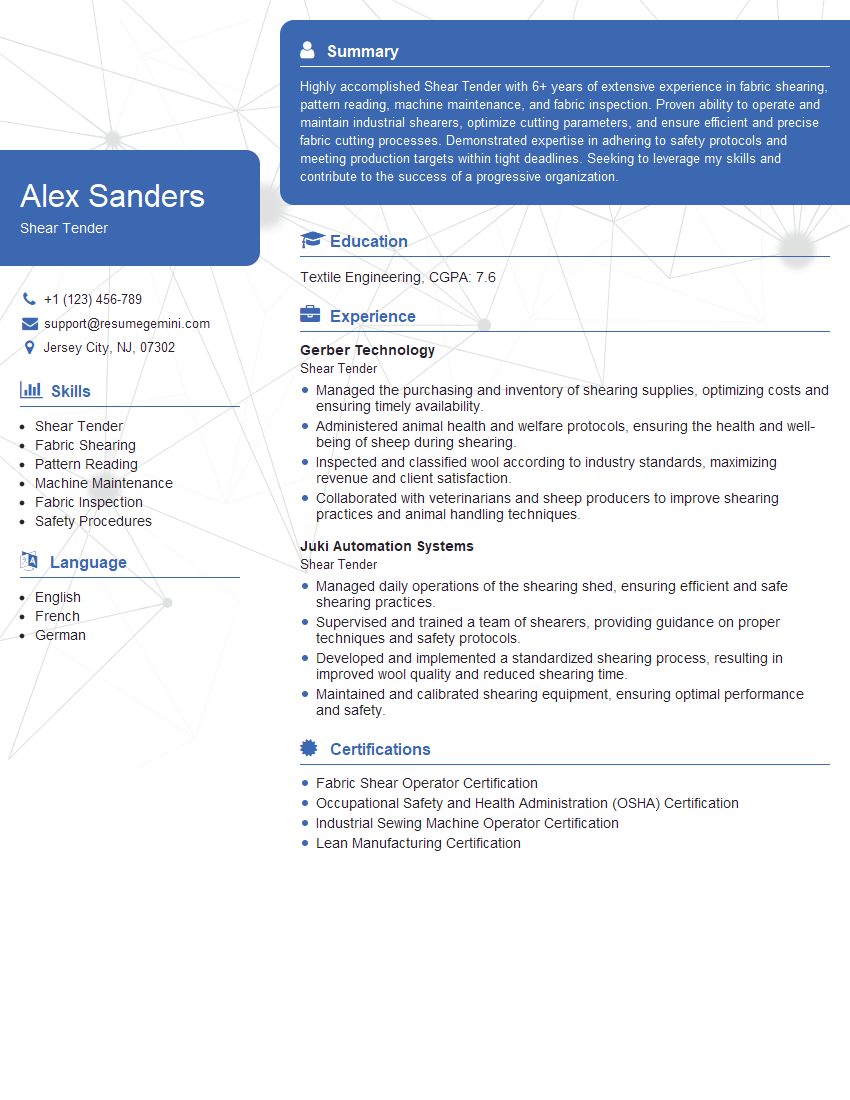

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shear Tender

1. Describe the general process of shearing sheep.

The general process of shearing sheep involves the following steps:

- Preparing the sheep for shearing, which includes catching, restraining, and cleaning the sheep.

- Positioning the sheep on the shearing board or platform in a comfortable and secure manner.

- Using electric shears to remove the wool from the sheep’s body, starting from the belly and working towards the back and sides.

- Rolling and classing the wool to remove any contaminants and prepare it for market.

- Releasing the shorn sheep back into the pasture or holding area.

2. How do you ensure the welfare of the sheep during the shearing process?

Ensuring the welfare of the sheep during shearing is paramount. Key measures include:

- Handling the sheep gently and with respect throughout the process.

- Using sharp and well-maintained shears to minimize discomfort to the sheep.

- Providing a calm and stress-free environment during shearing.

- Monitoring the sheep for any signs of distress or injury and taking appropriate action.

- Adhering to industry best practices and regulations regarding sheep shearing.

3. What are the different types of shearing equipment used in the industry?

The primary types of shearing equipment used in the industry include:

- Electric shears: These are handheld devices powered by electricity, commonly used for large-scale shearing operations.

- Manual shears: These are handheld devices operated by hand, often preferred for smaller flocks or delicate shearing tasks.

- Shearing combs and cutters: These are interchangeable parts that determine the length and style of the cut.

- Wool handling equipment: This includes wool rollers, presses, and classing tables used to process and prepare the shorn wool.

4. How do you maintain and sharpen shearing equipment to ensure optimal performance?

Maintaining and sharpening shearing equipment is crucial for efficient and effective shearing:

- Regular cleaning and lubrication of the equipment to prevent rust and wear.

- Sharpening the shears regularly using a specialized grinding tool.

- Checking the tension and alignment of the shearing combs and cutters.

- Replacing worn or damaged parts promptly to maintain optimal performance.

- Following the manufacturer’s instructions for proper maintenance and care.

5. Describe the different techniques used for shearing sheep depending on the breed and wool type.

The shearing technique varies based on the breed of sheep and the type of wool:

- Merino sheep: Known for their fine wool, they require a delicate touch and shorter shearing strokes.

- Crossbred sheep: Have a mix of wool types, requiring a combination of shearing techniques.

- Long-wool sheep: Their wool is longer and coarser, demanding longer shearing strokes.

- Wet sheep: Shearing wet sheep requires special techniques to prevent damage to the wool and discomfort to the sheep.

6. How do you assess the quality of shorn wool and determine its value?

Assessing wool quality involves several factors:

- Micron count: Measures the fineness of the wool fibers.

- Staple length: Refers to the length of the wool fibers.

- Strength and elasticity: Determines the durability and resilience of the wool.

- Cleanliness: Assesses the presence of contaminants such as dirt or vegetation.

- Color and luster: Influences the aesthetic appeal and value of the wool.

7. What are the common health and safety hazards associated with sheep shearing and how do you mitigate them?

Common hazards in sheep shearing include:

- Cuts and abrasions from sharp shears.

- Repetitive strain injuries from prolonged shearing.

- Respiratory issues from wool dust.

- Animal bites or kicks.

- Slips and falls on wet or uneven surfaces.

Mitigation measures include:

- Wearing appropriate protective gear.

- Using sharp and well-maintained shears.

- Taking regular breaks to prevent fatigue.

- Providing proper ventilation and dust control.

- Following safe handling techniques for sheep.

- Maintaining a clean and organized work area.

8. Describe your experience with crutching and how it differs from full shearing.

Crutching involves removing wool from specific areas of the sheep, such as the belly, tail, and legs. It differs from full shearing in the following ways:

- Purpose: Crutching is done for hygiene and comfort, while full shearing removes the entire fleece.

- Frequency: Crutching is typically done more frequently than full shearing.

- Technique: Crutching uses shorter shearing strokes and focuses on specific areas, while full shearing covers the entire body.

9. How do you handle difficult or aggressive sheep during the shearing process?

Dealing with difficult sheep requires patience and experience:

- Assess the situation: Observe the sheep’s behavior and identify potential triggers.

- Calm the sheep: Use a gentle and reassuring approach, avoiding sudden movements or loud noises.

- Secure the sheep: If necessary, use a restraining device to prevent injury to the sheep or shearer.

- Proceed with caution: Shear the sheep carefully, avoiding sensitive areas and taking breaks as needed.

- Seek assistance: If unable to handle the sheep safely, seek help from a colleague or veterinarian.

10. Describe your knowledge of sustainable shearing practices and how you incorporate them into your work.

Sustainable shearing practices include:

- Minimizing waste: Proper wool handling and disposal to reduce environmental impact.

- Animal welfare: Ensuring the sheep’s comfort and well-being throughout the shearing process.

- Energy efficiency: Using energy-efficient shearing equipment and practices.

- Water conservation: Minimizing water usage during shearing and wool processing.

- Education and training: Sharing knowledge and best practices with other shearers and stakeholders.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shear Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shear Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Shear Tenders play a crucial role in the smooth functioning of textile production. Their primary responsibilities include handling and maintaining various types of industrial shears used in textile cutting processes.

1. Shear maintenance and adjustments

Shear Tenders must ensure that all shears are properly maintained. This involves regular lubrication, sharpening, and adjusting to achieve optimal cutting performance.

- Lubricating and oiling shears to prevent wear and tear

- Sharpening blades to maintain sharpness and precision

- Adjusting blade clearances and tensions to achieve accurate cuts

2. Operation and monitoring

Shear Tenders are responsible for operating shears and monitoring their performance during production. They must ensure that shears are operating smoothly and efficiently, delivering clean and precise cuts.

- Feeding fabric into shears and monitoring the cutting process

- Inspecting the quality of cuts to ensure accuracy and consistency

- Identifying and reporting any issues with shears or cutting parameters

3. Safety and quality control

Shear Tenders must adhere to safety protocols and ensure that shears are operated in a safe manner. They also contribute to quality control by continuously monitoring the accuracy and precision of shears.

- Following proper safety procedures while handling shears

- Wearing protective gear and maintaining a clean work area

- Inspecting cuts for defects and reporting any inconsistencies

4. Troubleshooting and repairs

Shear Tenders must be able to identify and resolve common issues with shears. They may perform minor repairs and adjustments to keep shears operational, minimizing production downtime.

- Diagnosing and troubleshooting shear malfunctions

- Performing simple repairs and adjustments, such as replacing blades

- Reporting major issues or repairs to supervisors or maintenance teams

Interview Tips

Preparing thoroughly for a Shear Tender interview is essential to showcase your skills and knowledge. Here are some tips to help you ace the interview:

1. Research the company and position

Familiarize yourself with the company’s history, values, and products. Research the specific role to understand the key responsibilities and qualifications required. This will help you tailor your answers to the interviewer’s expectations.

- Visit the company website and social media profiles

- Review the job description and identify the most relevant skills and experiences

- Network with people in the industry or connect with the company on LinkedIn

2. Highlight your technical skills

Emphasize your expertise in shear maintenance and operation. Describe your experience with different types of shears and the specific tasks you have performed. Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Provide examples of how you have maintained and adjusted shears to improve cutting accuracy

- Discuss your experience in troubleshooting and resolving common shear issues

- Highlight your understanding of shear safety protocols and quality control measures

3. Demonstrate your teamwork and communication skills

In a production environment, effective teamwork and communication are crucial. Share examples of how you have collaborated with colleagues to resolve issues or improve efficiency.

- Describe how you communicate with other team members, supervisors, and maintenance personnel

- Explain how you contribute to team efforts to maintain a clean and organized work environment

- Provide an example of how you have handled a challenging situation that required teamwork

4. Prepare questions for the interviewer

Asking thoughtful questions shows engagement and interest in the position. Prepare questions about the company’s growth plans, the role of the Shear Tender in the production process, or any other aspect of the job that you find intriguing.

- Ask about the company’s commitment to safety and quality

- Inquire about opportunities for professional development and advancement

- Express your interest in learning about the company’s sustainability initiatives

Next Step:

Now that you’re armed with the knowledge of Shear Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Shear Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini