Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Shearman position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

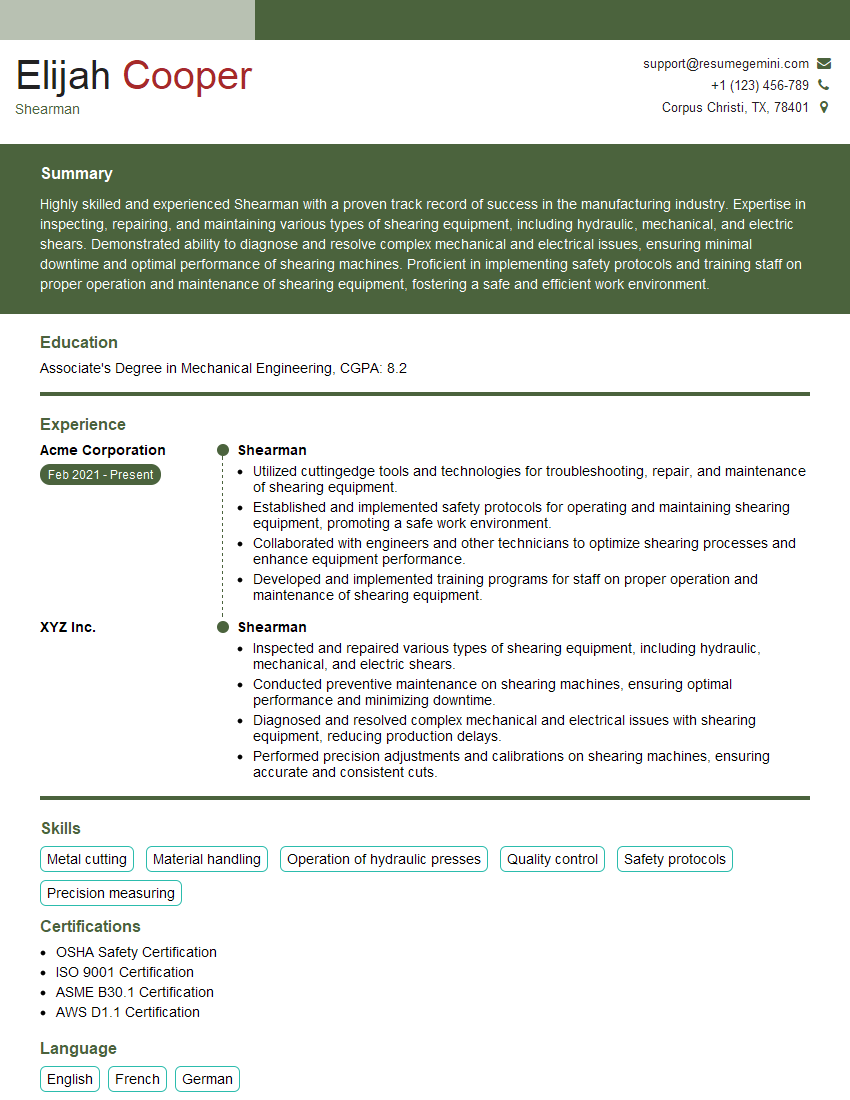

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shearman

1. What are the key components of a high-quality Shearman product?

The key components of a high-quality Shearman product include:

- Precision: Our products are manufactured to exacting tolerances, ensuring a high degree of accuracy and repeatability.

- Durability: Our products are made from high-quality materials and are designed to withstand the rigors of demanding applications.

- Reliability: Our products are designed and tested to provide consistent performance under a wide range of operating conditions.

- Efficiency: Our products are designed to maximize efficiency and minimize energy consumption.

- Safety: Our products are designed with safety in mind, incorporating features to protect users from injury.

2. Describe the different types of Shearman products and their applications.

Automotive

- Our automotive products include power steering pumps, fuel pumps, and water pumps. These products are designed to meet the specific performance and durability requirements of the automotive industry.

Industrial

- Our industrial products include hydraulic pumps, valves, and cylinders. These products are used in a wide range of industrial applications, such as construction, manufacturing, and mining.

Aerospace

- Our aerospace products include hydraulic systems, fuel systems, and landing gear. These products are designed to meet the stringent requirements of the aerospace industry for performance, reliability, and safety.

3. What are the advantages of using Shearman products?

The advantages of using Shearman products include:

- Quality: Our products are manufactured to exacting standards, ensuring a high degree of precision, durability, and reliability.

- Performance: Our products are designed to maximize performance and efficiency in a wide range of applications.

- Safety: Our products are designed with safety in mind, incorporating features to protect users from injury.

- Cost-effectiveness: Our products are competitively priced and offer a low cost of ownership over the long term.

- Customer support: We provide excellent customer support, including technical assistance, training, and spare parts.

4. What is the Shearman production process?

The Shearman production process is divided into the following steps:

- Design: Our products are designed using state-of-the-art software and engineering tools.

- Materials sourcing: We source our materials from trusted suppliers who meet our stringent quality standards.

- Manufacturing: Our products are manufactured using advanced manufacturing technologies, including CNC machining, injection molding, and assembly.

- Testing: Our products are tested at every stage of the production process to ensure they meet our high standards of quality and performance.

- Packaging and shipping: Our products are carefully packaged and shipped to ensure they arrive at their destination safely.

5. What are the Shearman quality control procedures?

The Shearman quality control procedures are designed to ensure that our products meet our high standards of quality and performance. These procedures include:

- Incoming inspection: All incoming materials are inspected to ensure they meet our specifications.

- In-process inspection: Products are inspected at every stage of the manufacturing process to identify and correct any defects.

- Final inspection: Finished products are inspected to ensure they meet our stringent quality standards.

- Statistical process control: We use statistical process control techniques to monitor our manufacturing processes and identify any areas for improvement.

- Customer feedback: We actively seek feedback from our customers to identify any areas where we can improve our products and services.

6. What are the Shearman research and development capabilities?

Shearman has a dedicated team of engineers and scientists who are constantly working to develop new products and technologies.

- We have state-of-the-art research and development facilities where we conduct research in a variety of areas, including materials science, fluid mechanics, and thermodynamics.

- We also collaborate with leading universities and research institutions to access the latest advancements in technology.

- Our research and development efforts are focused on developing products that meet the needs of our customers and that set new standards for performance, efficiency, and safety.

7. What is the Shearman environmental policy?

Shearman is committed to protecting the environment. Our environmental policy includes:

- Pollution prevention: We strive to prevent pollution at the source by using environmentally friendly materials and processes.

- Waste reduction: We minimize waste generation and recycle materials whenever possible.

- Energy conservation: We use energy-efficient technologies and practices throughout our operations.

- Employee training: We train our employees on environmental best practices.

- Compliance: We comply with all applicable environmental laws and regulations.

8. What is the Shearman safety policy?

Shearman is committed to providing a safe and healthy workplace for our employees. Our safety policy includes:

- Hazard identification and risk assessment: We identify and assess hazards in the workplace and take steps to minimize risks.

- Safe work procedures: We develop and implement safe work procedures for all tasks.

- Employee training: We train our employees on safe work practices.

- Safety equipment: We provide our employees with the necessary safety equipment.

- Emergency preparedness: We have emergency preparedness plans in place.

9. What is the Shearman quality management system?

Shearman has a comprehensive quality management system that is certified to the ISO 9001 standard. Our quality management system includes:

- Quality planning: We plan and document the quality requirements for our products and services.

- Quality control: We implement and maintain quality control procedures to ensure that our products and services meet our requirements.

- Quality assurance: We conduct quality audits to verify that our quality management system is effective.

- Continuous improvement: We continually review and improve our quality management system.

10. What are the Shearman social responsibility initiatives?

Shearman is committed to being a responsible corporate citizen. Our social responsibility initiatives include:

- Employee development: We invest in the development of our employees, providing them with training and opportunities to grow their careers.

- Community involvement: We support our local communities through donations and volunteerism.

- Environmental protection: We are committed to protecting the environment and reducing our environmental impact.

- Supplier responsibility: We require our suppliers to adhere to our environmental and social responsibility standards.

- Ethics and compliance: We conduct our business ethically and comply with all applicable laws and regulations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shearman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shearman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Shearmen, also known as sheep shearers, play a crucial role in the wool industry by expertly removing wool from sheep. Their primary responsibility lies in ensuring a clean, efficient, and humane shearing process.

1. Sheep Shearing

Shearmen are highly skilled in using shearing equipment, including shears and combs, to remove the fleece from sheep. They must possess exceptional dexterity and precision to protect the animals from harm while obtaining high-quality wool.

- Operate shearing equipment safely and efficiently

- Handle sheep with care and minimize stress

2. Wool Handling

Shearmen are responsible for handling the shorn wool. They must grade and sort the wool based on quality, ensuring that it meets industry standards. Proper wool handling prevents contamination and maintains the value of the fleece.

- Grade and sort wool according to specific criteria

- Package and store wool appropriately

3. Animal Welfare

Shearmen prioritize the well-being of sheep throughout the shearing process. They must ensure that sheep are treated humanely, with minimal stress and discomfort. Proper animal handling reduces the risk of injury and promotes the health of the flock.

- Adhere to animal welfare guidelines

- Monitor sheep for any signs of distress

4. Equipment Maintenance

Shearmen are responsible for maintaining and repairing shearing equipment. They must ensure that equipment is in good working order to achieve efficient and safe shearing. Regular maintenance extends the lifespan of equipment and reduces the risk of accidents.

- Perform regular equipment inspections

- Troubleshoot and repair equipment as needed

Interview Tips

For candidates seeking to ace an interview for a shearman position, preparation is essential. Here are some tips and hacks that can increase your chances of success.

1. Research the Industry

Gain a thorough understanding of the wool industry, including shearing techniques, wool grading, and animal welfare practices. This knowledge will demonstrate your interest and commitment to the field.

- Read industry publications and attend webinars

- Visit shearing operations to observe professionals in action

2. Practice Your Skills

If possible, practice shearing sheep under the guidance of an experienced shearman. This hands-on experience will enhance your confidence and demonstrate your abilities. Consider volunteering at a local farm or joining a shearing crew.

- Familiarize yourself with different shearing equipment

- Learn proper sheep handling and wool grading techniques

3. Emphasize Safety

Shearmen must prioritize safety for themselves and the animals they handle. Highlight your knowledge of safety protocols and your commitment to working in a safe and responsible manner.

- Discuss your understanding of animal welfare guidelines

- Explain your experience in using shearing equipment safely

4. Be Adaptable

Shearmen often work in diverse conditions and with different types of sheep. Emphasize your adaptability and willingness to learn new techniques. Demonstrate your ability to handle challenges and maintain a positive attitude.

- Discuss your experience working in different environments

- Highlight your ability to problem-solve and find solutions

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Shearman interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.