Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sheet Ironworker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

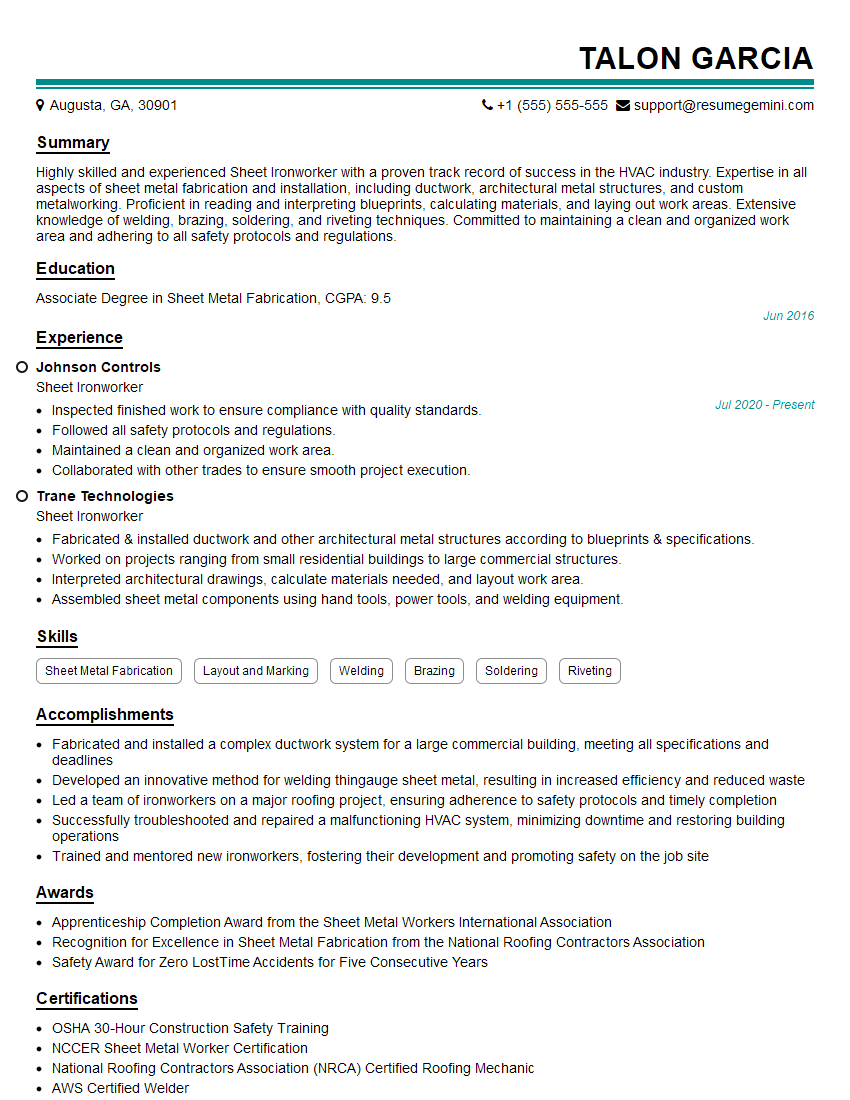

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Ironworker

1. What are the different types of sheet metal used in construction?

– Galvanized steel – Stainless steel – Aluminum – Copper

2. What are the different types of sheet metal joining methods?

- Soldering

- Brazing

- Welding

Soldering

- Uses a soldering iron to melt solder onto the metal surfaces

- Creates a strong, permanent bond

Brazing

- Uses a higher temperature to melt the solder

- Creates a stronger bond than soldering

Welding

- Uses an electric arc to melt the metal surfaces together

- Creates the strongest and most permanent bond

3. What are the different types of sheet metal fabrication techniques?

- Cutting

- Bending

- Forming

Cutting

- Can be done with a variety of tools, including shears, plasma cutters, and water jets

- Accurate cutting is essential for creating precise sheet metal parts

Bending

- Used to create curves and angles in sheet metal

- Can be done with a variety of tools, including brakes, rolls, and presses

Forming

- Used to create complex shapes in sheet metal

- Can be done with a variety of tools, including dies, presses, and hammers

4. What are the different types of sheet metal finishing processes?

- Painting

- Coating

- Plating

Painting

- Used to protect the sheet metal from corrosion and wear

- Can be applied in a variety of colors and finishes

Coating

- Used to improve the appearance and durability of the sheet metal

- Can be applied in a variety of materials, including epoxy, polyurethane, and vinyl

Plating

- Used to apply a thin layer of metal to the sheet metal

- Can be used to improve the corrosion resistance, wear resistance, and electrical conductivity of the sheet metal

5. What are the safety precautions that must be taken when working with sheet metal?

- Wear proper protective clothing, including gloves, safety glasses, and a hard hat

- Use sharp tools and equipment

- Be aware of the potential for cuts and lacerations

- Keep the work area clean and free of debris

- Follow all safety regulations

6. What are the challenges of working with sheet metal?

- Sheet metal can be sharp and can cause cuts and lacerations

- Sheet metal can be heavy and can be difficult to handle

- Sheet metal can be slippery and can be difficult to hold onto

- Sheet metal can be easily damaged, so care must be taken when working with it

7. What are the rewards of working with sheet metal?

- Sheet metal is a versatile material that can be used to create a variety of products

- Sheet metal is a durable material that can last for many years

- Sheet metal is a relatively inexpensive material, making it a good choice for a variety of applications

8. What are the different types of sheet metal tools?

- Hand tools, such as shears, pliers, and hammers

- Power tools, such as drills, saws, and grinders

- Specialized tools, such as brakes, rolls, and presses

9. What are the different types of sheet metal projects?

- Architectural projects, such as roofing, siding, and gutters

- Industrial projects, such as ductwork, tanks, and machinery guards

- Automotive projects, such as body panels, hoods, and trunks

10. What are the career opportunities for sheet metal workers?

- Sheet metal workers can work in a variety of industries, including construction, manufacturing, and automotive

- Sheet metal workers can earn a good salary and benefits

- Sheet metal workers can advance to management positions

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Ironworker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Ironworker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet Ironworkers are highly skilled craftsmen responsible for the fabrication, installation, and maintenance of sheet metal components and systems used in commercial, industrial, and residential construction.

1. Fabrication

Lay out and fabricate sheet metal components according to blueprints and specifications utilizing various tools and equipment including shears, brakes, and rollers.

- Select and cut sheet metal to precise dimensions.

- Form and shape metal using specialized machinery and techniques.

2. Installation

Install sheet metal components on buildings, including roofing, siding, gutters, and ductwork, ensuring proper fit and function.

- Secure sheet metal components using fasteners, adhesives, and sealants.

- Install and connect HVAC systems, including air ducts and vents.

3. Maintenance

Repair and maintain sheet metal components to ensure optimal performance and prevent premature failure.

- Inspect sheet metal components for damage or corrosion.

- Repair or replace damaged or malfunctioning components.

4. Safety

Follow all safety regulations and procedures to ensure a safe work environment.

- Wear appropriate safety gear, including hard hats, safety glasses, and gloves.

- Operate machinery and equipment safely and in accordance with best practices.

Interview Tips

Preparing thoroughly for an interview is crucial for success. Here are some tips to help you ace your Sheet Ironworker interview:

1. Research the Company and Position

Before the interview, research the company and the specific position you’re applying for. This will give you a good understanding of their business operations, industry trends, and the skills and experience they’re seeking in a candidate.

- Visit the company’s website to learn about their history, mission, and services.

- Check out industry publications and news articles to stay informed about current trends and best practices in sheet metal fabrication.

2. Practice Your Answers

Take some time to practice answering common interview questions related to sheet metal fabrication and construction. This will help you organize your thoughts and deliver clear and concise responses.

- Prepare for questions about your experience with different types of sheet metal and fabrication techniques.

- Practice describing your skills in installing and maintaining HVAC systems.

3. Highlight Your Safety Knowledge

Safety is paramount in sheet metal fabrication and construction. Emphasize your understanding of safety regulations and procedures, and your commitment to maintaining a safe work environment.

- Discuss your experience with following safety protocols and using personal protective equipment.

- Explain how you prioritize safety on the job site and take proactive steps to prevent accidents.

4. Bring a Portfolio (Optional)

If you have a portfolio of your work, consider bringing it to the interview. This can showcase your skills and provide tangible evidence of your experience in sheet metal fabrication.

- Include examples of your work, such as photos or drawings of completed projects.

- Highlight your attention to detail, craftsmanship, and ability to meet project specifications.

5. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Show the interviewer that you’re passionate about sheet metal fabrication and eager to contribute to their team.

- Dress professionally and arrive on time for the interview.

- Be respectful and courteous to the interviewer and ask thoughtful questions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sheet Ironworker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!