Feeling lost in a sea of interview questions? Landed that dream interview for Sheet Layer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Sheet Layer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

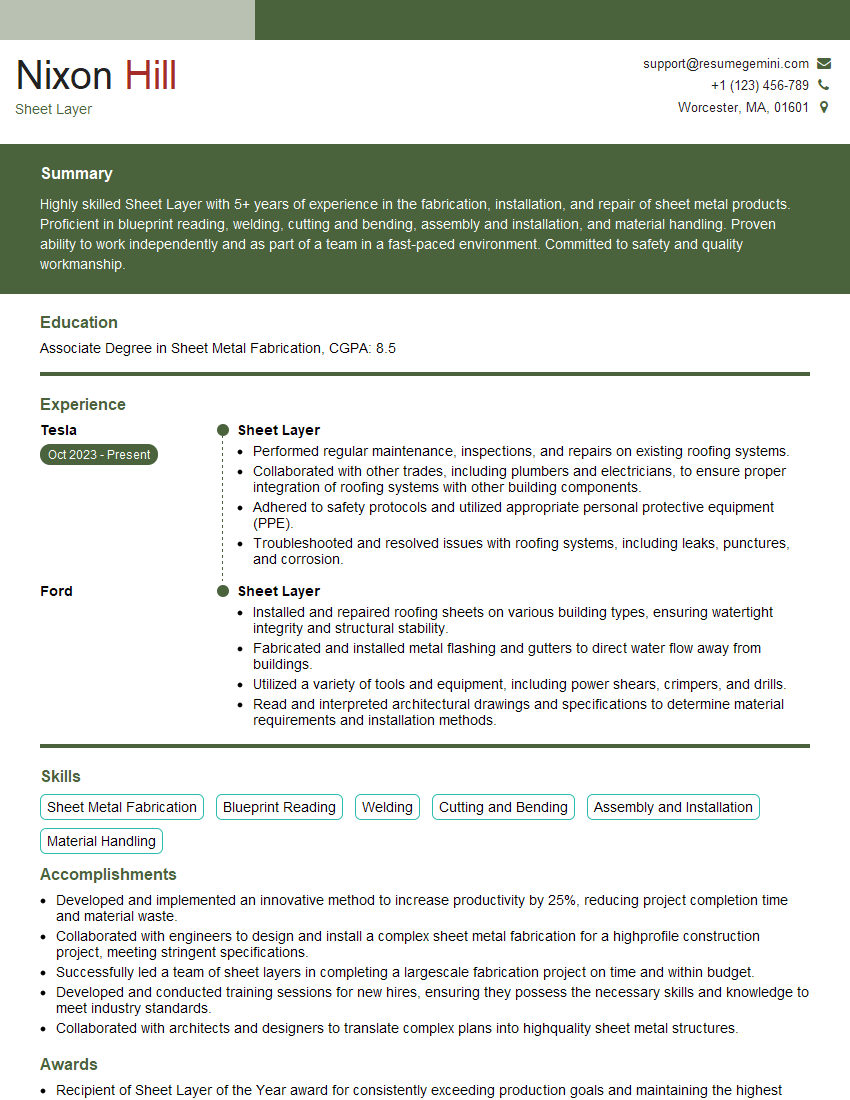

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Layer

1. Which materials do you prefer to work with when installing metal sheets?

In metal sheet installation, I have extensive experience working with a range of materials, including:

- Galvanized steel

- Aluminum

- Stainless steel

- Copper

2. What are the common joint types used in sheet metal fabrication and which one is your favorite?

When joining sheet metal pieces, various joint types are employed. I am proficient in the following:

Butt joint

- Easy to create

- Strong and durable

Edge joint

- Provides a strong and sealed connection

- Can be used to join sheets of different thicknesses

Flat lock seam

- Weather-resistant and durable

- Commonly used in roofing and siding applications

Snap lock seam

- Easy to assemble and disassemble

- Provides a concealed connection

My preferred joint type is the flat lock seam due to its exceptional strength, durability, and weather resistance.

3. What types of methods are used to fasten sheet metal together?

To fasten sheet metal components, I commonly employ a variety of methods:

- Welding: MIG, TIG, and spot welding

- Riveting

- Screwing

- Adhesives

4. What are the important factors to consider when selecting fasteners for sheet metal?

When choosing fasteners for sheet metal, I consider several key factors:

- Type of metal being fastened

- Thickness of the metal

- Load requirements

- Environmental conditions

- Cost

5. What is your approach to ensuring proper alignment and precision when installing sheet metal?

To achieve proper alignment and precision in sheet metal installation, I follow a systematic approach:

- Use measuring tools such as rulers, squares, and levels

- Mark reference points and guidelines

- Use clamps and jigs to hold pieces in place

- Check alignment and dimensions throughout the installation process

6. Describe the process of installing a standing seam metal roof.

Installing a standing seam metal roof involves the following steps:

- Prepare the roof deck and install underlayment

- Position and secure the eave flashing

- Install the metal panels, starting from the eave and working upwards

- Interlock the panels using standing seams

- Install ridge caps and other trim pieces

- Seal all seams and penetrations

7. What are the benefits and drawbacks of using a coil line to produce sheet metal?

Benefits:

- High production efficiency

- Consistent quality

- Reduced material waste

Drawbacks:

- High initial investment cost

- Limited flexibility in terms of material thickness and width

- Requires skilled operators

8. How do you maintain and store sheet metal to prevent damage and corrosion?

To maintain and store sheet metal effectively, I adhere to the following practices:

- Store in a dry, well-ventilated area

- Protect from moisture and excessive heat

- Use proper supports and racking to prevent bending or warping

- Apply protective coatings or oils to prevent corrosion

- Inspect regularly for any signs of damage or deterioration

9. Can you explain the concept of sheet metal gauging and its significance?

Sheet metal gauging refers to the measurement of its thickness. It is critical because it determines the properties and applications of the metal. Thicker gauges indicate a sturdier and more durable material, while thinner gauges are more flexible and lightweight. Understanding sheet metal gauging allows for appropriate material selection based on specific project requirements.

10. What are some common challenges you have encountered in sheet metal fabrication and how did you overcome them?

In sheet metal fabrication, I have faced various challenges, including:

- Complex designs: I use advanced fabrication techniques and specialized tools to achieve precise cuts and bends.

- Tight tolerances: I employ meticulous measuring and calibration methods to ensure components meet exact specifications.

- Material handling: I follow proper safety protocols and utilize appropriate equipment to safely handle large or heavy sheet metal pieces.

- Welding and joining: I possess expertise in various welding methods and ensure strong and durable joints.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Layer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Layer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet Layer is a professional responsible for installing and repairing sheetrock or drywall in residential and commercial buildings. They are also responsible for preparing surfaces, applying joint compound, taping seams, and sanding and finishing walls and ceilings.

1. Installation of Sheetrock or Drywall

Sheet Layer’s install sheetrock or drywall on walls and ceilings, using nails, screws, or adhesives.

- Study blueprints and specifications to determine the layout and dimensions of the walls and ceilings.

- Cut and fit sheetrock or drywall to the appropriate size and shape.

- Secure sheetrock or drywall to walls and ceilings using nails, screws, or adhesives.

2. Preparation of Surfaces

Sheet Layer’s prepare surfaces for the installation of sheetrock or drywall.

- Remove old wallpaper, paint, or other coverings from walls and ceilings.

- Repair damaged walls and ceilings by patching holes or cracks.

- Apply a primer to walls and ceilings to ensure proper adhesion of sheetrock or drywall.

3. Application of Joint Compound

Sheet Layer’s apply joint compound to seams between sheets of sheetrock or drywall.

- Mix joint compound according to manufacturer’s instructions.

- Apply joint compound to seams between sheets of sheetrock or drywall using a trowel.

- Smooth and finish joint compound to create a seamless surface.

4. Taping Seams

Sheet Layer’s apply tape to seams between sheets of sheetrock or drywall.

- Cut tape to the appropriate length and apply it to seams between sheets of sheetrock or drywall.

- Press tape into joint compound to create a strong bond.

- Smooth and finish tape to create a seamless surface.

5. Sanding and Finishing Walls and Ceilings

Sheet Layer’s sand and finish walls and ceilings to prepare them for painting or other finishes.

- Sand walls and ceilings to remove any rough spots or imperfections.

- Apply a primer to walls and ceilings to seal the surface and prevent stains.

- Apply paint or other finishes to walls and ceilings according to manufacturer’s instructions.

Interview Tips

Preparing for an interview for a Sheet Layer position can help you make a great impression on the hiring manager and increase your chances of getting the job. Here are some tips to help you prepare:

1. Research the company and the position

Take some time to research the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture, values, and what they’re looking for in a Sheet Layer.

- Visit the company’s website to learn about their products or services, history, and mission statement.

- Read online reviews of the company from current or former employees to get an idea of what it’s like to work there.

- Search for news articles or press releases about the company to learn about their recent accomplishments or challenges.

2. Practice answering common interview questions

There are some common interview questions that you’re likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?”. It’s helpful to practice answering these questions ahead of time so that you can deliver your answers confidently and clearly.

- Write down a list of potential interview questions and practice answering them out loud.

- Ask a friend or family member to conduct a mock interview with you.

- Record yourself answering interview questions and play it back to identify areas for improvement.

3. Be prepared to talk about your skills and experience

The interviewer will want to know about your skills and experience as a Sheet Layer. Be prepared to discuss your experience installing and repairing sheetrock or drywall, preparing surfaces, applying joint compound, taping seams, and sanding and finishing walls and ceilings.

- Quantify your accomplishments whenever possible. For example, instead of saying “I installed sheetrock,” say “I installed over 100,000 square feet of sheetrock in a commercial building.”.

- Use action verbs to describe your skills and experience. For example, instead of saying “I’m a hard worker,” say “I’m a highly motivated and results-oriented individual with a strong work ethic.”.

- Be prepared to talk about your experience using specific tools and equipment.

4. Be enthusiastic and positive

Interviewers are looking for candidates who are enthusiastic about the position and the company. Be sure to convey your interest in the position and the company during the interview. Be positive and upbeat, and be sure to smile.

- Dress professionally and arrive on time for your interview.

- Make eye contact with the interviewer and speak clearly and confidently.

- Be respectful of the interviewer’s time and answer their questions honestly and thoroughly.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Sheet Layer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.