Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Sheet Manufacturing Supervisor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Sheet Manufacturing Supervisor so you can tailor your answers to impress potential employers.

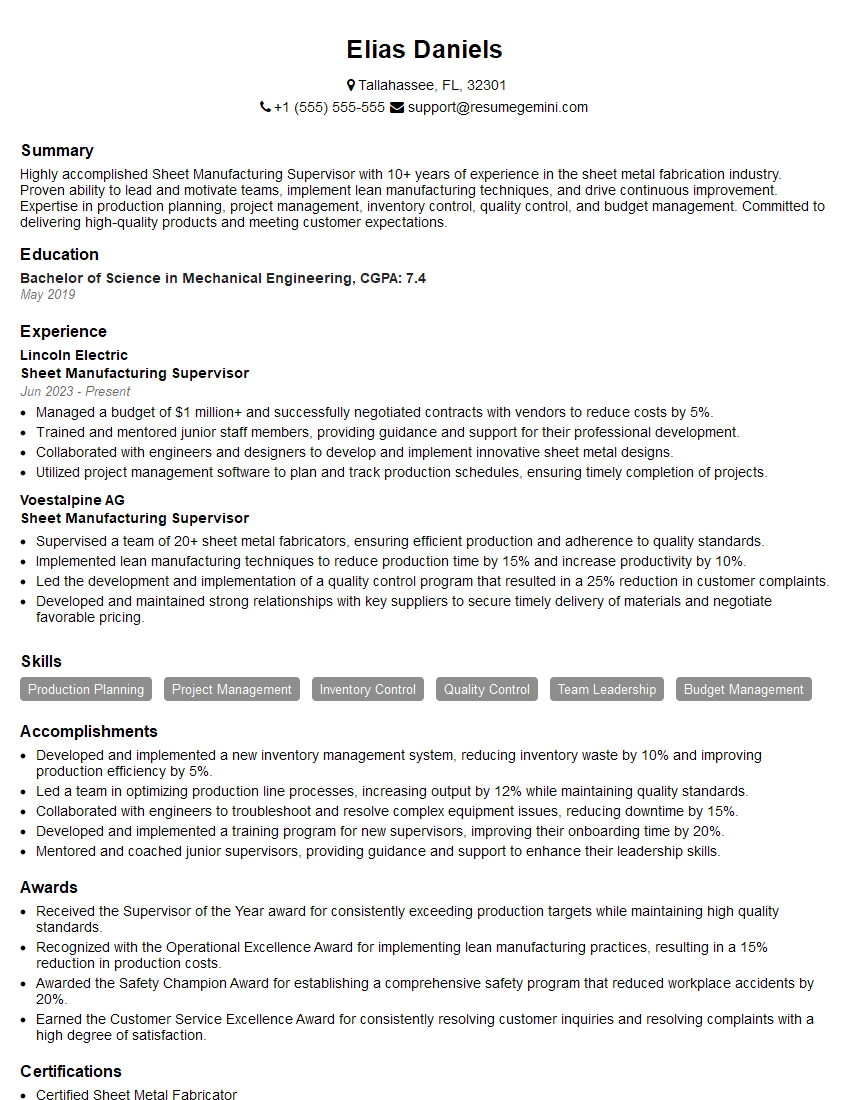

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Manufacturing Supervisor

1. How would you optimize a sheet metal fabrication process to enhance productivity and cost-effectiveness?

- Identify inefficiencies and bottlenecks throughout the process.

- Implement lean manufacturing principles to streamline operations and reduce waste.

- Automate tasks where feasible to improve efficiency and precision.

- Analyze production data to identify areas for improvement and make data-driven decisions.

- Regularly review and update fabrication processes to stay current with industry best practices.

2. Describe the different types of sheet metal forming processes and their applications.

- Bending: Used to create angles and curves in sheet metal, such as for ducts, brackets, and panels.

- Stamping: Involves using presses to cut, form, and emboss sheet metal into complex shapes.

- Roll forming: Continuous process where sheet metal is passed through a series of rollers to create uniform cross-sections, such as for roofing and siding.

- Welding: Used to join sheet metal pieces together using various techniques, including MIG, TIG, and spot welding.

- Spinning: Rotational process where sheet metal is formed into circular or cylindrical shapes, such as for dishware and lampshades.

3. How do you ensure the quality of sheet metal products and meet customer specifications?

- Establish and adhere to strict quality control standards and procedures.

- Conduct regular inspections at various stages of the manufacturing process.

- Use precision measuring tools and instruments to ensure dimensional accuracy.

- Train and empower employees on the importance of quality and attention to detail.

- Seek customer feedback to identify any areas for improvement.

4. What are the key safety considerations in sheet metal fabrication and how do you implement safety measures?

- Properly train and equip employees with personal protective equipment.

- Establish clear safety protocols and enforce their adherence.

- Regularly inspect and maintain machinery and equipment to prevent accidents.

- Provide adequate ventilation to prevent exposure to hazardous fumes and dust.

- Promote a culture of safety awareness and encourage employees to report any potential hazards.

5. How would you manage a team of sheet metal fabricators to achieve optimal performance and productivity?

- Set clear goals and expectations for the team.

- Provide training and support to enhance their skills and knowledge.

- Foster a collaborative and supportive work environment.

- Implement performance management systems to track progress and provide feedback.

- Recognize and reward achievements to motivate the team.

6. What is your approach to managing production schedules and ensuring timely delivery of orders?

- Develop realistic production schedules based on capacity and lead times.

- Monitor progress regularly and identify potential delays.

- Communicate with customers to provide accurate delivery estimates.

- Coordinate with suppliers to secure timely delivery of raw materials.

- Implement contingency plans to mitigate potential disruptions.

7. How do you handle customer complaints and resolve issues related to sheet metal products?

- Listen attentively to the customer’s concerns.

- Thoroughly investigate the issue to identify the root cause.

- Propose and implement solutions in a timely and professional manner.

- Follow up with the customer to ensure satisfaction.

- Document the complaint and resolution for future reference.

8. How do you stay up-to-date with the latest trends and technologies in sheet metal fabrication?

- Attend industry conferences and exhibitions.

- Read industry publications and online resources.

- Engage with suppliers and manufacturers to learn about new products and technologies.

- Encourage innovation and experimentation within the team.

- Invest in research and development to enhance capabilities.

9. How do you prioritize and manage multiple projects simultaneously to ensure successful execution?

- Develop a clear project plan and timeline.

- Assign responsibilities and delegate tasks effectively.

- Regularly monitor progress and identify potential roadblocks.

- Communicate updates and ensure alignment among team members.

- Seek support from senior management when needed.

10. How do you measure and evaluate the performance of a sheet metal fabrication operation?

- Establish key performance indicators (KPIs) related to productivity, quality, and customer satisfaction.

- Collect and analyze data to track performance against targets.

- Identify areas for improvement and implement corrective actions.

- Regularly review and adjust performance metrics to ensure they remain relevant.

- Share performance results with the team to foster continuous improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Manufacturing Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Manufacturing Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet Manufacturing Supervisors are responsible for the day-to-day operations of a sheet manufacturing plant. They oversee the production process, ensure quality control, and manage the plant’s workforce. Some of the key job responsibilities of a Sheet Manufacturing Supervisor include:1. Production Management

Plan, schedule, and coordinate production activities to ensure efficient and timely completion of orders.

- Develop and implement production plans to optimize production efficiency and meet customer requirements.

- Monitor production progress, identify potential bottlenecks, and take corrective actions to ensure smooth operations.

2. Quality Control

Establish and maintain quality standards for products and processes and monitor production to ensure compliance.

- Conduct regular quality inspections to ensure products meet specifications and customer requirements.

- Identify and resolve quality issues, implement corrective actions to prevent recurrence.

3. Workforce Management

Lead, motivate, and train a team of production operators to achieve production goals and maintain a positive work environment.

- Provide clear instructions, set performance targets, and offer support to production operators.

- Conduct performance evaluations, provide feedback, and identify areas for improvement.

4. Equipment Maintenance

Ensure that production equipment is properly maintained, calibrated, and repaired to minimize downtime and maintain optimal performance.

- Create and implement equipment maintenance schedules to prevent breakdowns and minimize costly repairs.

Interview Tips

To ace the interview for a Sheet Manufacturing Supervisor position, it’s important to prepare thoroughly and showcase your relevant skills and experience. Here are a few tips to help you succeed:1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you’re applying for. This will help you understand their industry, goals, and the key responsibilities of the role.

2. Highlight Your Experience

When answering interview questions, focus on highlighting your relevant experience and skills. Use specific examples to demonstrate your ability to manage production, ensure quality, and lead a team.

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers aloud. Anticipate questions about your experience in sheet manufacturing, your leadership style, and your approach to quality control.

4. Ask Thoughtful Questions

At the end of the interview, take the opportunity to ask thoughtful questions about the company, the position, and the industry. This shows that you’re engaged and eager to learn more.

5. Follow Up

After the interview, send a thank-you note to the interviewer expressing your appreciation for their time and reiterating your interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sheet Manufacturing Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!