Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sheet Metal Apprentice position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

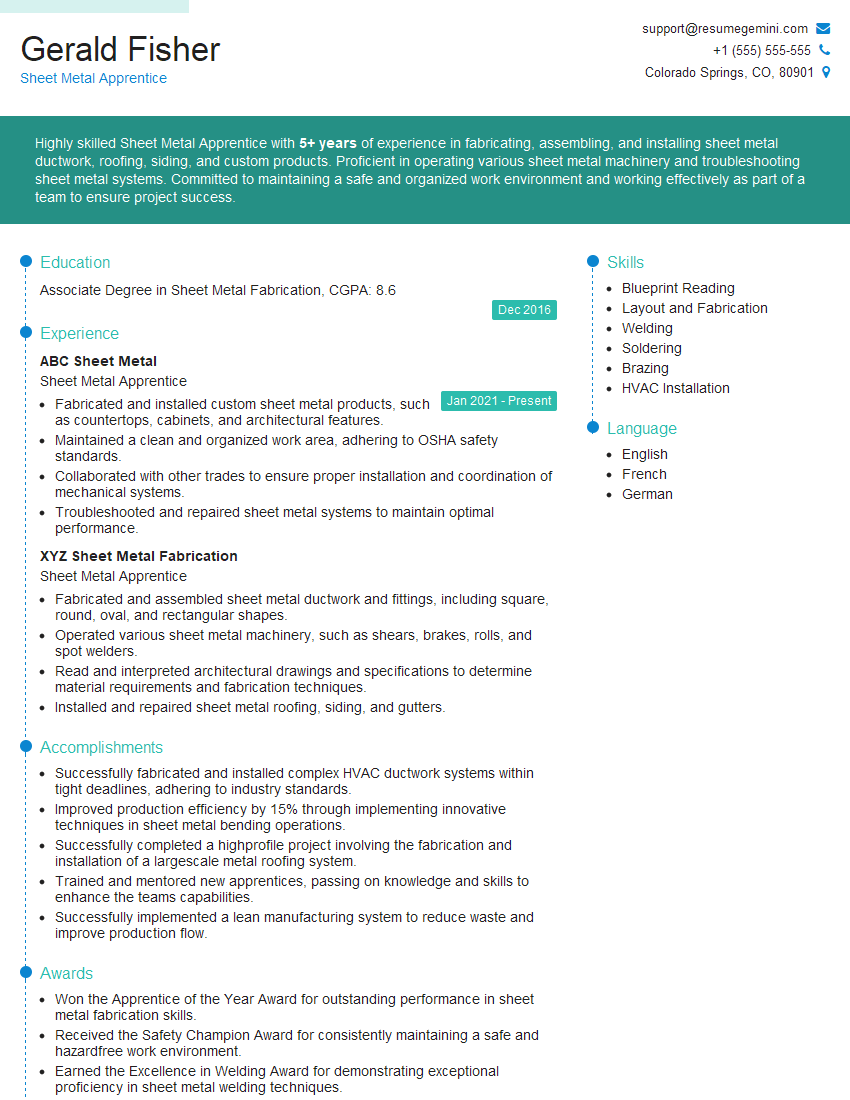

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Metal Apprentice

1. What are the different types of sheet metal and their applications?

- Galvanized Steel: Corrosion-resistant, used in roofing, siding, and automotive parts.

- Stainless Steel: Heat-resistant, used in cookware, appliances, and medical equipment.

- Aluminum: Lightweight, corrosion-resistant, used in aircraft, marine components, and window frames.

- Copper: Conductive, used in electrical wiring, roofing, and plumbing.

- Brass: Durable, wear-resistant, used in musical instruments, jewelry, and hardware.

2. Explain the process of cutting sheet metal.

Shear Cutting

- Uses a shear to cut straight lines and curves.

- Produces clean, precise cuts with minimal distortion.

Plasma Cutting

- Uses a plasma torch to create clean, high-temperature cuts in various thicknesses.

- Versatile and suitable for cutting complex shapes.

3. Describe the different types of sheet metal bending operations.

- Folding: Bending sheet metal along a straight line without stretching.

- Rolling: Continuously bending sheet metal into a cylindrical or conical shape.

- Flanging: Turning the edge of sheet metal at a right angle.

- Bending: Creating curved shapes in sheet metal using a press brake.

4. What are the safety precautions to be followed when working with sheet metal?

- Wear appropriate safety gear (gloves, eye protection, earplugs).

- Clear work area of trip hazards and debris.

- Handle sharp edges carefully to avoid cuts.

- Use power tools with caution and follow manufacturer’s instructions.

- Be aware of potential pinch points and electrical hazards.

5. What is the purpose of annealing sheet metal?

- Softens metal, making it more pliable and easier to shape.

- Relieves stress and strain in the metal, improving its ductility.

- Prevents metal from cracking or fracturing during forming operations.

6. Explain the different welding processes used in sheet metal fabrication.

- MIG Welding: Uses a consumable wire electrode and a shielding gas, suitable for various metals.

- TIG Welding: Uses a non-consumable tungsten electrode and a separate shielding gas, produces high-quality welds.

- Spot Welding: Uses pressure and heat to weld two pieces of sheet metal together at specific points.

7. What are the common types of sheet metal layout and development tools?

- Measuring Tapes and Rulers: Determine dimensions and mark cutting lines.

- Squares and Protractors: Create angles and determine parallel lines.

- Templates and Patterns: Guide cutting and bending operations to ensure accuracy.

- Scribers and Marking Pens: Transfer designs and measurements onto sheet metal.

8. How do you ensure the accuracy and quality of sheet metal parts?

- Use precise measuring tools and follow specifications.

- Inspect parts regularly throughout the fabrication process.

- Use jigs and fixtures to hold parts securely during forming and welding.

- Test parts for dimensional accuracy, strength, and functionality.

9. Describe the importance of sheet metal finishing techniques.

- Improve appearance and protect against corrosion.

- Examples: painting, powder coating, galvanizing.

- Enhance durability and extend lifespan of sheet metal parts.

10. How do you keep up to date with the latest advancements in sheet metal fabrication?

- Attend industry conferences and workshops.

- Read technical journals and online resources.

- Network with other sheet metal professionals.

- Stay informed about new materials, tools, and techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Metal Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Metal Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet Metal Apprentices support Sheet Metal Workers and other skilled tradespeople in the fabrication, installation, and maintenance of sheet metal products, systems, and structures. Their duties encompass a range of tasks that contribute to the successful completion of sheet metal projects.

1. Assist in Sheet Metal Fabrication

Apprentices assist in the fabrication of sheet metal components, ducts, and fittings by utilizing various tools and equipment, including shears, brakes, and welders. They ensure accuracy in measurements, cut materials to specified dimensions, and shape and join sheet metal pieces to create the desired assemblies.

2. Install and Repair Sheet Metal Products

Apprentices assist in the installation and repair of sheet metal products, such as roofing, siding, gutters, and downspouts. They help to position and secure components, seal seams and joints, and complete installations according to specifications.

3. Perform Maintenance Tasks

Apprentices assist in the maintenance and repair of sheet metal systems and structures. They conduct inspections, clean and lubricate components, and make minor repairs and adjustments as needed to ensure optimal performance and safety.

4. Learn and Apply Sheet Metal Principles

Apprentices receive on-the-job training and classroom instruction in sheet metal principles and practices. They study blueprint reading, material properties, fabrication techniques, and installation methods to develop their skills and knowledge.

Interview Tips

Preparing for a Sheet Metal Apprentice interview requires a combination of research, practice, and self-reflection. By following these tips, candidates can increase their chances of making a positive impression and showcasing their qualifications.

1. Research the Company and Industry

Familiarize yourself with the company’s background, products or services, and industry trends. This knowledge will demonstrate your interest in the opportunity and help you tailor your answers to the specific needs of the organization.

2. Practice Your Answers to Common Interview Questions

Prepare thoughtful and concise answers to frequently asked interview questions, such as those related to your skills, experience, and motivation for pursuing a career in sheet metal. Practice delivering your answers aloud to improve your articulation and confidence.

3. Highlight Your Hands-on Skills

Emphasize your practical abilities and experience in working with sheet metal. Provide specific examples of your proficiency in using tools, fabricating components, and installing systems. Explain how these skills have contributed to successful projects.

4. Show Enthusiasm and a Willingness to Learn

Express your passion for the sheet metal trade and eagerness to develop your skills. Discuss your interest in the apprenticeship program and explain why you are seeking this opportunity. Show that you are committed to learning and growing in the field.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest. Prepare questions that relate to the company, the apprenticeship program, or the sheet metal industry. This will indicate your curiosity and desire to gather more information.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sheet Metal Apprentice interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!