Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sheet Metal Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

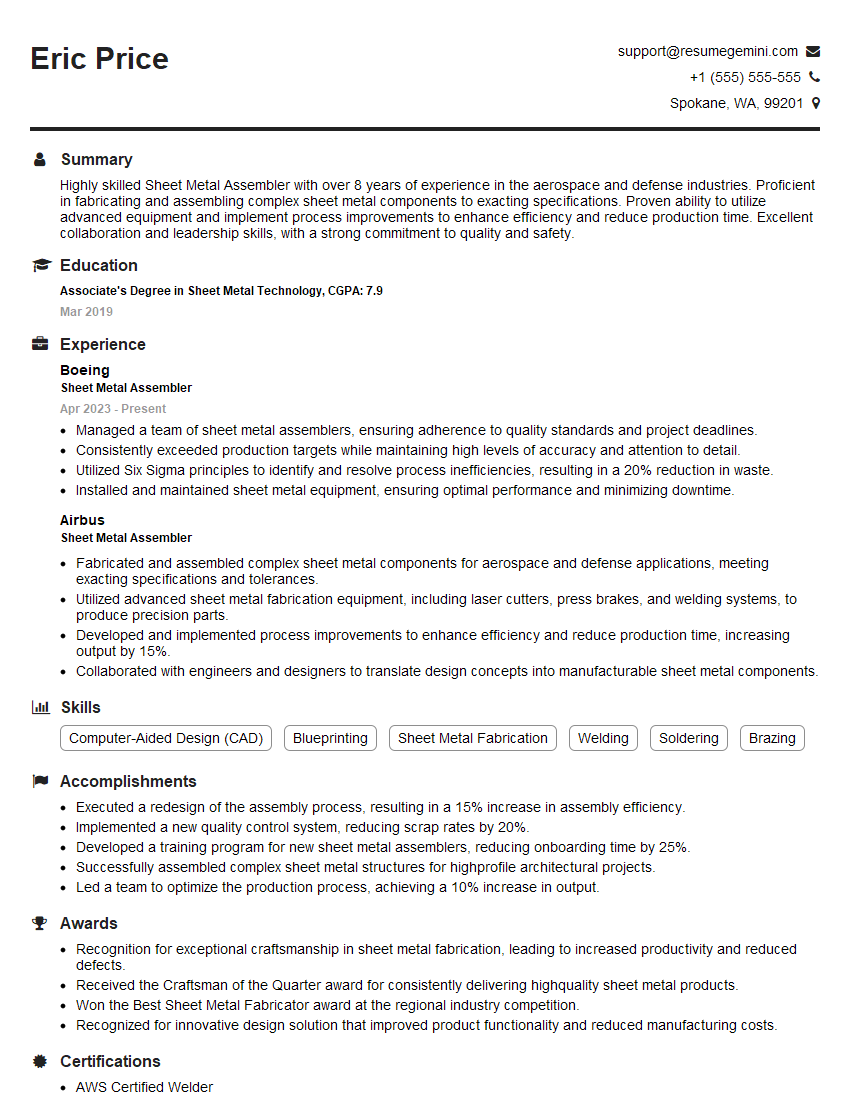

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Metal Assembler

1. Which sheet metal layout and fabrication software tools are you familiar with?

I am proficient in a variety of sheet metal layout and fabrication software tools, including:

- AutoCAD

- SolidWorks

- Mastercam

- Catia

- NX

2. What factors should be considered when determining the bend radius of a sheet metal part?

Material type

- Different materials have different bend radii, which must be taken into account to avoid cracking or tearing.

Thickness of the sheet metal

- Thicker sheet metal requires a larger bend radius to avoid cracking.

Angle of the bend

- The angle of the bend also affects the bend radius, with sharper bends requiring a larger radius.

Grain direction of the sheet metal

- The grain direction of the sheet metal should be considered to ensure that the bend is made in the correct direction.

3. How do you ensure the accuracy of your sheet metal assemblies?

I use a variety of techniques to ensure the accuracy of my sheet metal assemblies, including:

- Using precision measuring tools, such as calipers and micrometers

- Checking the dimensions of each component against the engineering drawings

- Assembling the components in a controlled environment to minimize errors

- Using jigs and fixtures to ensure that the components are assembled correctly

4. What is your experience working with different types of sheet metal?

I have experience working with a variety of sheet metals, including:

- Steel

- Stainless steel

- Aluminum

- Brass

- Copper

5. How do you handle complex sheet metal assemblies?

I break down complex sheet metal assemblies into smaller, more manageable components.

- I create a detailed assembly plan.

- I use jigs and fixtures to ensure the accuracy of the assembly.

- I test the assembly to ensure that it meets the customer’s requirements.

6. What are your strengths as a Sheet Metal Assembler?

My strengths as a Sheet Metal Assembler include:

- My attention to detail

- My ability to follow instructions

- My ability to work independently and as part of a team

- My commitment to quality

7. How do you stay up-to-date on the latest sheet metal fabrication techniques?

I stay up-to-date on the latest sheet metal fabrication techniques by:

- Reading trade magazines

- Attending industry conferences

- Taking online courses

8. What is your experience with welding?

I have experience with a variety of welding processes, including:

- MIG welding

- TIG welding

- Arc welding

- Spot welding

9. How do you ensure the quality of your welds?

I ensure the quality of my welds by:

- Using the correct welding process for the material and application

- Preparing the joint properly

- Using the correct welding parameters

- Inspecting the weld after it is complete

10. What is your experience with CNC machines?

I have experience with a variety of CNC machines, including:

- Press brakes

- Shears

- Laser cutters

- Plasma cutters

11. How do you program and operate CNC machines?

I program and operate CNC machines by:

- Creating a CAD model of the part

- Generating the CNC code from the CAD model

- Setting up the CNC machine

- Loading the CNC code into the machine

- Running the CNC machine

- Inspecting the finished part

12. What is your experience with quality control?

I have experience with a variety of quality control techniques, including:

- Visual inspection

- Dimensional inspection

- Functional testing

- Destructive testing

13. How do you ensure that your sheet metal assemblies meet the customer’s requirements?

I ensure that my sheet metal assemblies meet the customer’s requirements by:

- Reviewing the customer’s drawings and specifications

- Inspecting the raw materials

- Following the assembly procedures

- Testing the finished assembly

- Providing the customer with a certificate of conformity

14. What is your experience with lean manufacturing?

I have experience with a variety of lean manufacturing techniques, including:

- Value stream mapping

- 5S

- Kanban

- Kaizen

15. How do you use lean manufacturing techniques to improve your productivity?

I use lean manufacturing techniques to improve my productivity by:

- Identifying and eliminating waste

- Improving the flow of materials and information

- Empowering employees to make decisions

- Continuously improving processes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Metal Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Metal Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet metal assemblers play a crucial role in the fabrication industry, working with sheet metal components and assembling them into various structures, units, and products. Their key responsibilities include:

1. Reading and understanding blueprints and engineering drawings

Assemblers must be able to accurately interpret blueprints and engineering drawings to understand the specifications and assembly instructions of the project.

2. Preparing sheet metal components

This involves cutting, bending, forming, and punching sheet metal components according to the specified dimensions and shapes using precision tools and machinery.

3. Assembling components

Assemblers fit and join sheet metal components together using various techniques such as welding, riveting, screwing, and adhering. They ensure proper alignment and secure connections.

4. Inspecting assemblies

Assemblers check the assembled products for accuracy, quality, and compliance with specifications. They use measuring tools and gauges to ensure that the final product meets the required standards.

5. Following safety protocols

Assemblers must adhere to all safety guidelines and regulations related to working with sheet metal and machinery to prevent accidents and injuries.

Interview Tips

To ace an interview for a Sheet Metal Assembler position, candidates should prepare themselves thoroughly by following these tips:

1. Research the company and position

Familiarize yourself with the company’s history, products or services, and the specific requirements of the Sheet Metal Assembler role.

2. Practice answering common interview questions

Review typical interview questions related to sheet metal assembly, such as your experience with specific tools, techniques, and safety protocols. Prepare clear and concise answers.

3. Highlight your skills and experience

Emphasize your proficiency in sheet metal assembly, including your knowledge of blueprints, ability to operate machinery, and attention to detail. Quantify your experience with specific examples.

4. Ask thoughtful questions

At the end of the interview, ask informed questions about the company, the role, and the industry to demonstrate your interest and engagement.

5. Prepare a portfolio (optional)

If possible, bring a portfolio or examples of your previous work to showcase your skills and craftsmanship to the interviewer.

Next Step:

Now that you’re armed with the knowledge of Sheet Metal Assembler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Sheet Metal Assembler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini