Feeling lost in a sea of interview questions? Landed that dream interview for Sheet Metal Computer Numerically Controlled (CNC) Programmer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Sheet Metal Computer Numerically Controlled (CNC) Programmer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

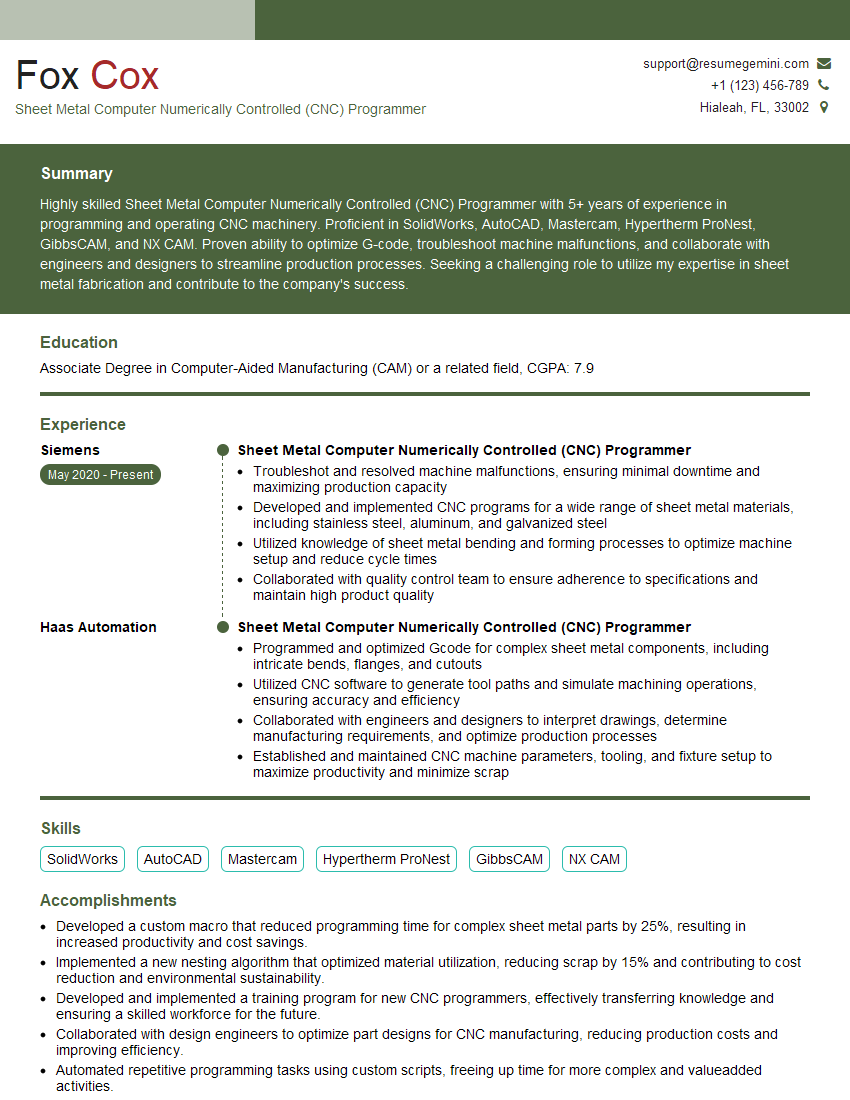

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Metal Computer Numerically Controlled (CNC) Programmer

1. What is the difference between incremental and absolute programming?

- Incremental programming refers to a programming method where each movement is specified relative to the current position of the machine.

- Absolute programming, on the other hand, specifies each movement relative to a fixed reference point.

- Incremental programming is often used for simple operations, while absolute programming is more suitable for complex operations.

2. What is the purpose of a tool compensation table?

How does it affect the accuracy of the CNC machine?

- A tool compensation table is used to compensate for the wear and tear of cutting tools.

- It contains information about the dimensions of each tool, as well as its wear rate.

- By using a tool compensation table, the CNC machine can automatically adjust its movements to account for the wear of the cutting tools.

- This helps to improve the accuracy of the machine and ensures that the parts produced are of high quality.

Benefits of using compensation table

- Improved accuracy

- Reduced scrap

- Increased productivity

3. What are the different types of CAM software?

- There are two main types of CAM software: 2D and 3D.

- 2D CAM software is used to create toolpaths for 2D shapes, such as those used in sheet metal fabrication.

- 3D CAM software is used to create toolpaths for 3D shapes, such as those used in mold making.

4. What are the advantages of using a post-processor?

- A post-processor is a software program that converts the output of a CAM system into a format that can be understood by the CNC machine.

- Using a post-processor can help to improve the accuracy and efficiency of the CNC machine.

- Post-processors can also be used to add custom features to the CNC machine, such as the ability to perform automatic tool changes.

5. What are the different types of CNC machines?

- There are many different types of CNC machines, each designed for a specific purpose.

- Some of the most common types of CNC machines include:

- Milling machines

- Turning machines

- Drilling machines

- Grinding machines

- Laser cutting machines

- Water jet cutting machines

6. What are the safety precautions that must be taken when working with a CNC machine?

- There are a number of safety precautions that must be taken when working with a CNC machine.

- These precautions include:

- Wearing appropriate safety gear, such as safety glasses, gloves, and earplugs.

- Keeping the work area clean and free of debris.

- Never operating the machine without proper training.

- Always following the manufacturer’s instructions.

7. What are the different types of cutting tools that can be used on a CNC machine?

- There are many different types of cutting tools that can be used on a CNC machine.

- The type of cutting tool that is used will depend on the material being cut and the desired finish.

- Some of the most common types of cutting tools include:

- End mills

- Drills

- Taps

- Reamer

8. What are the different types of materials that can be cut on a CNC machine?

- CNC machines can be used to cut a wide variety of materials, including:

- Metals

- Plastics

- Wood

- Composites

- The type of material that can be cut will depend on the capabilities of the CNC machine and the cutting tool being used.

9. What is the difference between a CNC router and a CNC mill?

- CNC routers and CNC mills are both CNC machines that can be used to cut a variety of materials.

- The main difference between the two types of machines is the type of cutting tool that they use.

- CNC routers use a rotating cutting tool, while CNC mills use a stationary cutting tool.

- CNC routers are typically used for cutting softer materials, such as wood and plastics, while CNC mills are typically used for cutting harder materials, such as metals.

10. What is the future of CNC machining?

- The future of CNC machining is bright.

- As technology continues to develop, CNC machines will become even more powerful and versatile.

- This will allow them to be used for a wider range of applications, including the manufacturing of complex parts and the production of custom products.

- In addition, the development of new materials and cutting tools will make it possible to cut even harder and more exotic materials.

- As a result, CNC machining is poised to play an increasingly important role in the manufacturing industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Metal Computer Numerically Controlled (CNC) Programmer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Metal Computer Numerically Controlled (CNC) Programmer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet Metal Computer Numerically Controlled (CNC) Programmers are responsible for creating and modifying CNC programs that guide CNC machines in the production of sheet metal components. They work closely with engineers and designers to ensure that the programs are accurate and efficient, and that the finished products meet the required specifications.

1. Create and modify CNC programs

CNC Programmers use specialized software to create and modify CNC programs. These programs contain instructions that tell the CNC machine how to move its tools and cut the sheet metal. The programs must be precise and accurate, as any errors can result in scrapped parts or even damage to the machine.

2. Optimize CNC programs for efficiency

In addition to creating and modifying CNC programs, CNC Programmers also need to optimize them for efficiency. This involves finding ways to reduce the cycle time of the program, which can save the company time and money. CNC Programmers can optimize programs by using efficient cutting paths, minimizing tool changes, and using the correct feeds and speeds.

3. Troubleshoot CNC programs and machines

CNC Programmers are also responsible for troubleshooting CNC programs and machines. If a program is not running correctly or if the machine is not functioning properly, the CNC Programmer will need to identify and fix the problem. This may involve making changes to the program, adjusting the machine settings, or calling for maintenance.

4. Train and supervise CNC machine operators

CNC Programmers may also be responsible for training and supervising CNC machine operators. This involves teaching operators how to use the CNC machine and how to run the CNC programs. CNC Programmers may also be responsible for overseeing the production process and ensuring that the finished products meet the required specifications.

Interview Tips

To ace an interview for a Sheet Metal CNC Programmer position, it is important to be prepared. Here are a few tips:

1. Research the company and the position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on its website, social media pages, and Glassdoor.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions ahead of time so that you can deliver your answers confidently and clearly.

3. Highlight your skills and experience

In your interview, be sure to highlight your skills and experience that are relevant to the position. For example, if you have experience creating and modifying CNC programs, be sure to mention this in your answer to the question “What are your strengths?”

4. Ask questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in the job and that you are engaged in the conversation.

5. Follow up

After the interview, send a thank-you note to the interviewer. This is a simple way to show your appreciation for their time and to reiterate your interest in the position.

Next Step:

Now that you’re armed with the knowledge of Sheet Metal Computer Numerically Controlled (CNC) Programmer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Sheet Metal Computer Numerically Controlled (CNC) Programmer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini