Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Sheet Metal Foreman interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Sheet Metal Foreman so you can tailor your answers to impress potential employers.

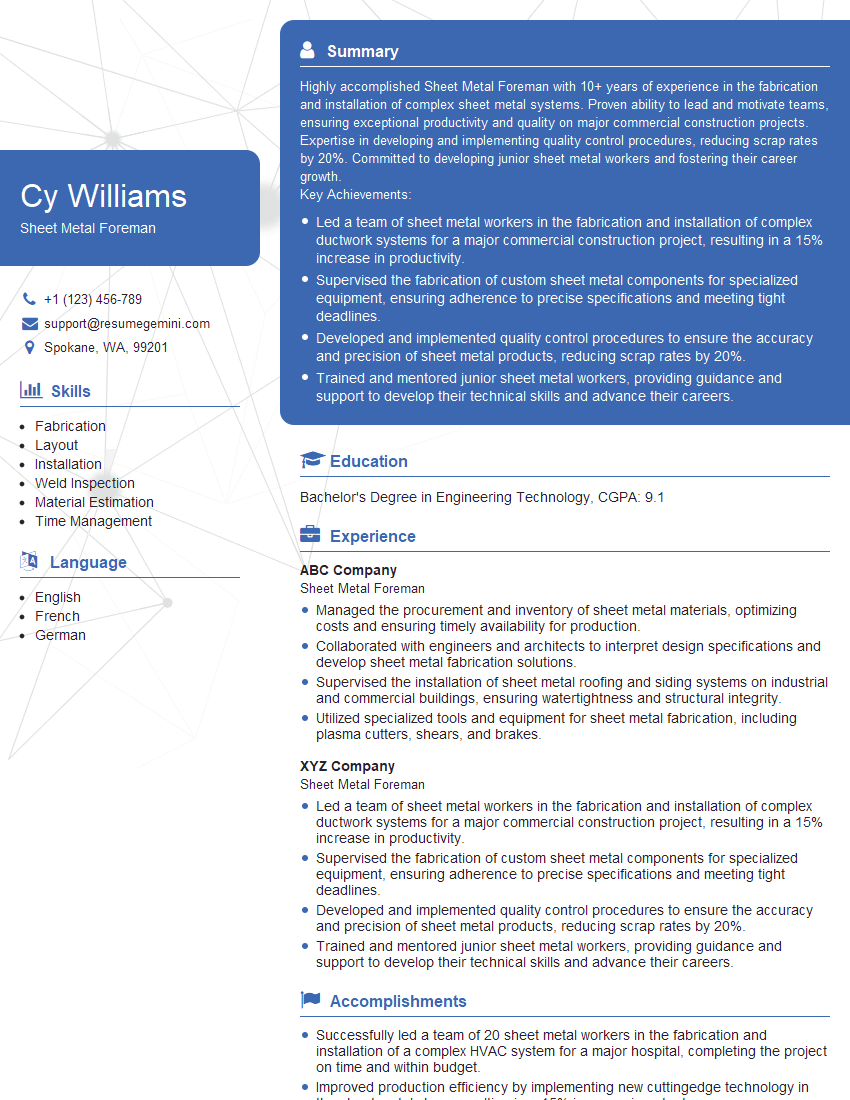

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Metal Foreman

1. Explain the process of fabricating a sheet metal ductwork system?

The process of fabricating a sheet metal ductwork system typically involves the following steps:

- Designing the ductwork system based on the project specifications.

- Selecting the appropriate sheet metal material and thickness based on the system requirements.

- Cutting the sheet metal to the desired shapes and sizes using a variety of tools such as shears, nibblers, and plasma cutters.

- Bending and forming the sheet metal into the required shapes and configurations using brakes, rolls, and other bending equipment.

- Assembling the ductwork components using techniques such as welding, riveting, or seaming.

- Installing the ductwork system in the building or structure.

- Testing and balancing the ductwork system to ensure proper airflow and performance.

2. Describe the different types of sheet metal joints and their applications?

Welded Joints

- Strong and durable, suitable for high-pressure and high-temperature applications.

- Require specialized equipment and skilled welders.

Riveted Joints

- Easy to assemble and disassemble, suitable for temporary or removable joints.

- Less strong than welded joints, but can be reinforced with multiple rivets.

Seamed Joints

- Formed by overlapping and interlocking sheet metal edges, creating a tight and durable joint.

- Used in ductwork and roofing applications.

3. How do you ensure the quality of sheet metal fabrication?

To ensure the quality of sheet metal fabrication, I follow several key practices:

- Using high-quality materials and components.

- Adhering to industry standards and specifications.

- Employing skilled and experienced fabricators.

- Implementing a quality control process to inspect and test products.

- Seeking feedback from customers and continuously improving processes.

4. What are the factors to consider when selecting sheet metal materials for a particular application?

When selecting sheet metal materials for a particular application, I consider the following factors:

- Strength and durability: The material must be able to withstand the anticipated loads and stresses.

- Corrosion resistance: The material must be resistant to corrosion in the environment where it will be used.

- Formability: The material must be able to be easily formed and shaped into the desired configuration.

- Cost: The material must be affordable within the budget of the project.

- Availability: The material must be readily available in the required quantities.

5. How do you manage a team of sheet metal fabricators?

To manage a team of sheet metal fabricators, I employ the following strategies:

- Clear communication: I ensure that my team understands the project requirements and goals.

- Delegation and empowerment: I delegate tasks and responsibilities to team members based on their skills and experience.

- Collaboration and teamwork: I foster a collaborative and supportive work environment.

- Performance monitoring: I regularly monitor team performance and provide feedback to improve productivity.

- Training and development: I invest in training and development opportunities for my team.

6. What are the latest trends and advancements in sheet metal fabrication technology?

- Computer-aided design (CAD): CAD software allows for precise and efficient design of sheet metal components.

- Computer-aided manufacturing (CAM): CAM software converts CAD designs into instructions for automated fabrication equipment.

- Laser cutting: Laser cutting provides high-precision and intricate cuts in sheet metal.

- Waterjet cutting: Waterjet cutting uses a high-pressure water jet to cut sheet metal, resulting in clean and burr-free edges.

- Additive manufacturing: 3D printing technology enables the creation of complex sheet metal shapes.

7. How do you stay up-to-date with the latest industry best practices?

To stay up-to-date with the latest industry best practices, I engage in the following activities:

- Attending industry events and conferences.

- Reading trade publications and technical journals.

- Participating in online forums and discussion groups.

- Consulting with experts and thought leaders in the field.

- Seeking continuing education and training opportunities.

8. How do you handle challenges and unexpected situations in sheet metal fabrication?

When faced with challenges and unexpected situations in sheet metal fabrication, I take the following steps:

- Analyze the situation: I assess the problem and gather all relevant information.

- Identify possible solutions: I brainstorm and consider different ways to address the challenge.

- Evaluate the options: I weigh the pros and cons of each potential solution.

- Implement the best solution: I choose the most effective and feasible solution and put it into action.

- Monitor the results: I track the progress and outcomes of the implemented solution.

9. What are your strengths and weaknesses as a Sheet Metal Foreman?

Strengths

- Strong technical expertise in sheet metal fabrication and installation.

- Excellent leadership and management skills.

- Ability to plan, organize, and execute projects efficiently.

- Proven ability to meet deadlines and quality standards.

- Excellent communication and interpersonal skills.

Weaknesses

- Limited experience in certain specialized sheet metal fabrication techniques.

- Can be a bit demanding at times, but always with the goal of achieving the best results.

10. Why are you interested in this Sheet Metal Foreman position?

I am eager to join your company as a Sheet Metal Foreman because I am confident that my skills and experience align perfectly with the requirements of this role. I am passionate about sheet metal fabrication and have a proven track record of success in leading teams and delivering high-quality results. I am excited about the opportunity to contribute my expertise to your organization and to work collaboratively with your team to achieve your business objectives.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Metal Foreman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Metal Foreman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Supervise and Lead Sheet Metal Team

- Hire, train, develop, and evaluate team members.

- Assign tasks, set deadlines, and monitor progress to ensure timely completion.

- Foster a positive work environment that promotes collaboration and teamwork.

2. Plan and Manage Sheet Metal Operations

- Plan and schedule production processes to meet deadlines and quality standards.

- Coordinate with other departments to ensure smooth workflow and resource allocation.

- Identify and implement process improvements to enhance efficiency and productivity.

3. Ensure Quality Control and Compliance

- Establish and enforce quality standards for sheet metal products and workmanship.

- Inspect finished products and ensure they adhere to specifications and industry regulations.

- Implement and maintain quality control systems to prevent defects and ensure customer satisfaction.

4. Manage Safety and Maintenance

- Enforce safety regulations and ensure a safe work environment for employees.

- Schedule and oversee maintenance of sheet metal equipment to maintain optimal performance.

- Train team members on safety protocols and ensure compliance with all applicable laws and regulations.

Interview Tips

1. Research the Company and Position

- Visit the company’s website and social media pages to learn about their culture, values, and industry standing.

- Review the job description thoroughly to identify the specific skills, experience, and qualifications required.

2. Highlight Relevant Experience and Skills

- Tailor your resume and cover letter to emphasize your experience in sheet metal fabrication, project management, and quality control.

- Quantify your accomplishments to demonstrate the impact of your work and the value you can bring to the organization.

3. Prepare for Common Interview Questions

- Practice answering questions about your leadership style, problem-solving abilities, and experience in driving production goals.

- Prepare examples of your successes in managing teams, improving processes, and ensuring quality compliance.

4. Ask Thoughtful Questions

- Ask questions during the interview to show your interest in the company, the position, and the industry trends.

- This demonstrates your engagement and gives you an opportunity to gain additional insights into the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sheet Metal Foreman interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!