Feeling lost in a sea of interview questions? Landed that dream interview for Sheet Metal Lay Out Worker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Sheet Metal Lay Out Worker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

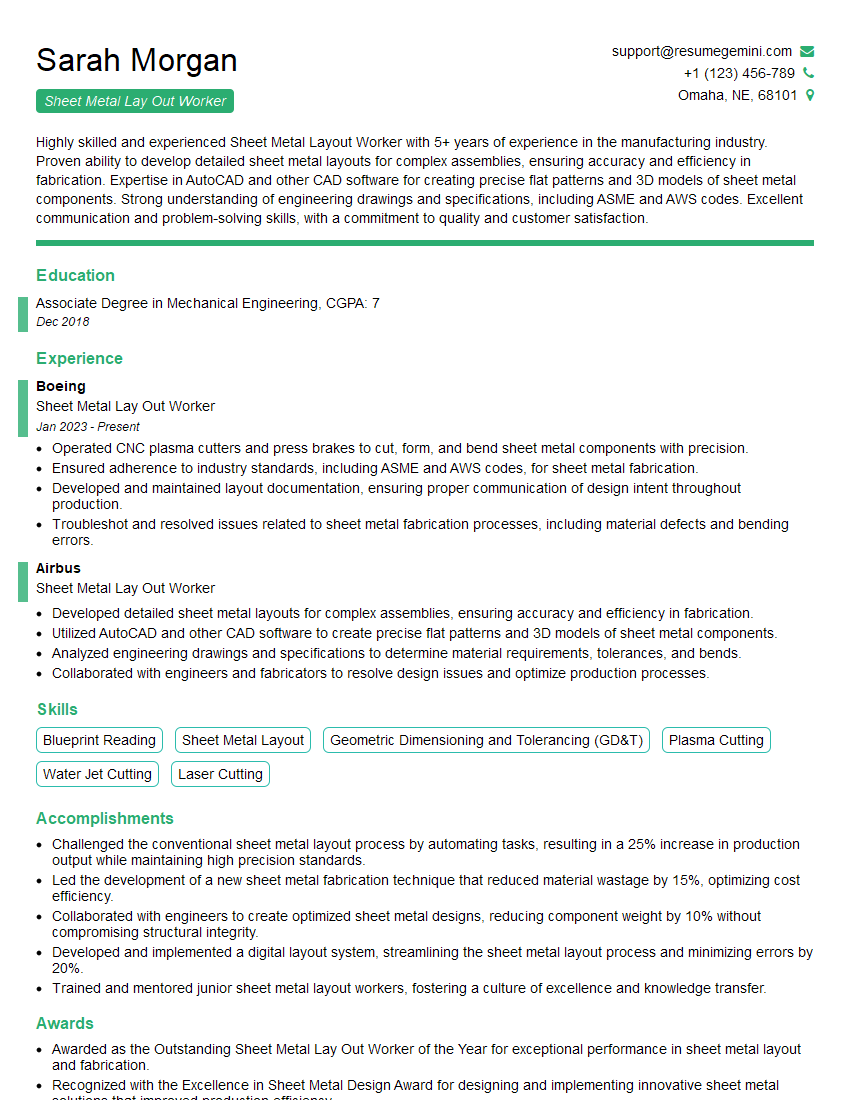

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Metal Lay Out Worker

1. How do you ensure the accuracy of your measurements when laying out sheet metal?

To ensure the accuracy of my measurements, I follow these steps:

- Use high-quality measuring tools that are regularly calibrated.

- Take multiple measurements to ensure consistency and minimize errors.

- Compare measurements with known dimensions or use a layout table to check accuracy.

- Account for material shrinkage and expansion due to temperature changes or forming processes.

2. Describe the different types of sheet metal fabricating processes you are familiar with and how you select the appropriate one for a given project.

Cutting Processes

- Shear cutting: Produces clean edges with minimal burrs

- Laser cutting: High-precision cutting with complex shapes

- Waterjet cutting: Versatile cutting for various materials and thicknesses

Forming Processes

- Bending: Creating angles or curves in sheet metal

- Rolling: Shaping sheet metal into cylindrical or conical forms

- Stamping: Pressing sheet metal into specific shapes using dies

Joining Processes

- Welding: Fusing metal pieces together using heat or electrical current

- Riveting: Joining metal pieces using rivets

- Bolting: Securing metal pieces with bolts and nuts

3. How do you interpret technical drawings and translate them into accurate layouts for sheet metal fabrication?

I follow a systematic approach to interpreting technical drawings:

- Study the drawing thoroughly, identifying dimensions, tolerances, and special features.

- Use a scale or measuring tool to determine actual dimensions from the drawing.

- Mark the layout on the sheet metal using a scribe, layout fluid, or other suitable marking tools.

- Double-check measurements and compare the layout with the drawing to ensure accuracy.

4. What are the factors to consider when selecting the appropriate material for a sheet metal fabrication project?

When selecting sheet metal material, I consider the following factors:

- Purpose and application of the fabricated part

- Strength and durability requirements

- Corrosion resistance and environmental factors

- Formability and ease of fabrication

- Cost and availability of the material

5. How do you handle complex geometries and tight tolerances in sheet metal fabrication?

To handle complex geometries and tight tolerances, I use a combination of techniques:

- Utilize advanced layout and measuring equipment, such as laser measuring systems or CNC machines.

- Employ specialized forming techniques, such as stretch forming or deep drawing, to achieve complex shapes.

- Work closely with engineers or designers to optimize designs for manufacturability.

- Conduct thorough inspections throughout the fabrication process to ensure compliance with tolerances.

6. What safety precautions do you take when working with sheet metal?

I prioritize safety by adhering to the following precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator.

- Use sharp tools properly and maintain them in good condition.

- Handle sheet metal carefully to avoid cuts or injuries.

- Follow established shop safety procedures and report any hazardous conditions.

- Stay alert and be aware of potential risks in the work area.

7. How do you stay up-to-date with the latest advancements in sheet metal fabrication technologies?

To stay current with advancements, I:

- Attend industry conferences and seminars

- Read trade publications and technical journals

- Take online courses or workshops

- Engage with vendors and suppliers to learn about new products and technologies

8. What is your experience with using CAD/CAM software in sheet metal fabrication?

I am proficient in using CAD/CAM software such as AutoCAD, SolidWorks, and CAMWorks. I use these tools for:

- Creating technical drawings and flat patterns

- Generating toolpaths for CNC machines

- Simulating fabrication processes to optimize efficiency

9. How do you ensure the quality of your work and meet customer specifications?

I maintain quality by:

- Thoroughly reviewing customer specifications and drawings

- Using precise measuring tools and equipment

- Conducting regular inspections throughout the fabrication process

- Seeking feedback from supervisors or designers if needed

- Documenting and recording all quality control measures

10. What are your strengths and weaknesses as a Sheet Metal Lay Out Worker?

My strengths include:

- Strong technical skills and attention to detail

- Proficiency in reading and interpreting blueprints

- Expertise in a variety of sheet metal fabrication techniques

- Ability to work independently and as part of a team

As for my weaknesses, I am always striving to:

- Enhance my knowledge of cutting-edge technologies

- Improve my efficiency and time management

- Develop my communication and interpersonal skills

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Metal Lay Out Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Metal Lay Out Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet Metal Lay Out Workers play a vital role in the fabrication process, ensuring the accurate layout and cutting of sheet metal components. Their primary responsibilities encompass:

1. Lay Out and Mark Materials

Analyzing blueprints, drawings, and specifications to determine precise cuts and bends for sheet metal components.

- Using measuring tools, such as rulers, calipers, and protractors, to mark the layout lines for cutting and bending operations.

- Making accurate cuts with hand tools or power equipment, such as shears, plasma cutters, and laser cutters, adhering to specified dimensions and angles.

2. Form and Fabricate Sheet Metal

Bending and forming sheet metal components using hand tools or specialized machinery, such as press brakes, to achieve desired shapes and contours.

- Assembling components using techniques such as riveting, welding, or soldering to create finished products.

- Inspecting the quality of fabricated sheet metal components to ensure accuracy and adherence to specifications.

3. Operate and Maintain Equipment

Operating and maintaining sheet metal fabrication equipment, including shears, press brakes, and welding machines, to ensure optimal performance.

- Performing regular maintenance tasks, such as cleaning, lubricating, and adjusting equipment to prevent breakdowns and extend its lifespan.

- Troubleshoot and resolve equipment issues to minimize downtime and maintain productivity.

4. Safety and Compliance

Adhering to safety regulations and guidelines to prevent accidents and maintain a safe work environment.

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and hearing protection.

- Following established safety protocols and procedures to minimize risks and ensure workplace safety.

Interview Tips

To ace the interview for a Sheet Metal Lay Out Worker position, it’s essential to prepare thoroughly and showcase your skills and experience. Here are some tips to help you make a strong impression:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and industry standing. Understanding their specific needs and the role’s requirements will help you tailor your answers during the interview.

- Visit the company’s website, LinkedIn page, and industry news articles to gather information.

- Review the job description thoroughly to identify the key skills and qualifications the employer is seeking.

2. Highlight Your Skills and Experience

Emphasize your technical abilities, such as layout marking, cutting, bending, and fabrication techniques. Quantify your accomplishments whenever possible to demonstrate your impact.

- Provide specific examples of projects where you successfully laid out and fabricated sheet metal components.

- Mention any certifications or training you have completed in sheet metal fabrication.

3. Showcase Your Problem-Solving Abilities

Employers value candidates who can identify and resolve problems efficiently. Highlight your ability to troubleshoot equipment issues and find solutions to production challenges.

- Share an example of a time you identified a problem in the fabrication process and implemented a solution.

- Explain how you approach troubleshooting and problem-solving in your work.

4. Demonstrate Your Safety Awareness

Emphasize your commitment to safety and your understanding of industry regulations. Describe your experience in following safety protocols and maintaining a safe work environment.

- Discuss any safety training or certifications you have obtained.

- Provide examples of your attention to detail and adherence to safety guidelines.

5. Prepare Questions

Asking thoughtful questions at the end of the interview shows your interest in the position and the company. Prepare questions that demonstrate your knowledge of the industry and your eagerness to learn more.

- Inquire about the company’s growth plans or the specific projects you would be involved in.

- Ask about opportunities for professional development and training.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sheet Metal Lay Out Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.