Are you gearing up for a career in Sheet Metal Layout Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Sheet Metal Layout Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

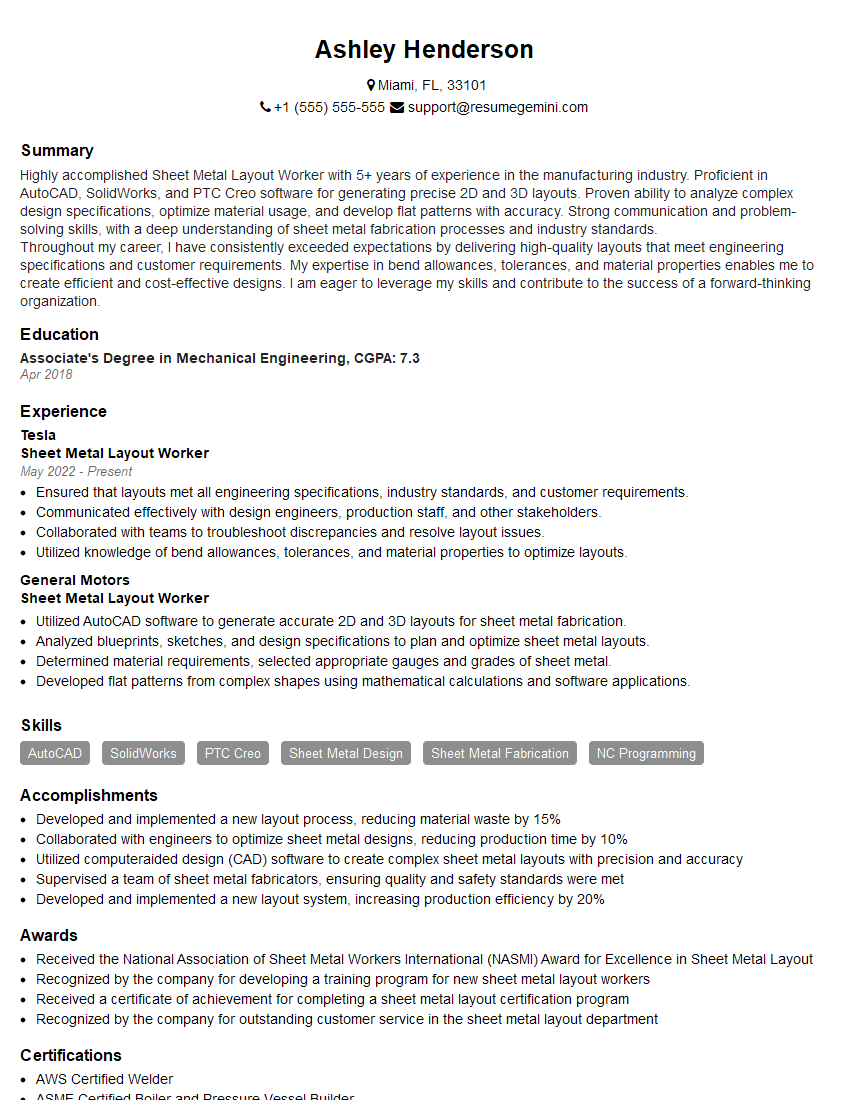

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Metal Layout Worker

1. What are the key responsibilities of a Sheet Metal Layout Worker?

As a Sheet Metal Layout Worker, I would be primarily responsible for developing and implementing efficient processes for laying out and marking sheet metal components based on design specifications. This would involve:

- Interpreting blueprints and technical drawings to determine the dimensions, shape, and layout of metal components.

- Using specialized software and tools to create accurate layout patterns, including but not limited to CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) systems.

- Marking and labeling sheet metal, ensuring precise alignment and placement of components for subsequent fabrication processes.

- Inspecting and verifying the accuracy of layout patterns before production.

- Collaborating with engineers, fabricators, and other team members to ensure the quality and efficiency of the final product.

2. What are the different layout and marking tools commonly used in sheet metal fabrication?

The most commonly used layout and marking tools in sheet metal fabrication include:

Measuring and layout tools:

- Rulers and measuring tapes

- Calipers

- Protractors

- Squares

- Dividers

- Scribers

Marking tools:

- Soapstone

- Marking pens

- Felt-tip markers

- Center punches

- Stamping tools

3. What are your favorite tools and what settings do you use typically?

My favorite tools for sheet metal layout are CAD and CAM systems. These software programs allow me to create accurate and detailed layout patterns quickly and efficiently. I typically use the following settings in CAD/CAM:

- Units: Inches or millimeters

- Decimal places: 3 or 4

- Line width: 0.010 inches or 0.25 millimeters

- Tolerance: +/- 0.005 inches or +/- 0.125 millimeters

These settings can be adjusted based on the specific requirements of the project.

4. How do you ensure the accuracy of layout patterns before production?

To ensure the accuracy of layout patterns before production, I follow these steps:

- Carefully review the blueprints and technical drawings.

- Create a rough layout sketch of the pattern.

- Enter the dimensions and specifications into the CAD/CAM system.

- Generate a preview of the layout pattern.

- Check the pattern for errors, such as incorrect dimensions, missing lines, or overlapping shapes.

- Make any necessary adjustments to the pattern.

- Verify the final layout pattern with the blueprint or drawing.

5. What is your experience with using CAD/CAM systems for sheet metal layout?

I have extensive experience using CAD/CAM systems for sheet metal layout. I have worked with a variety of CAD/CAM software programs, including AutoCAD, SolidWorks, and Mastercam. I am proficient in creating 2D and 3D models, developing layout patterns, and generating NC code for CNC machines.

6. How do you stay up-to-date with the latest developments in sheet metal layout techniques?

I stay up-to-date with the latest developments in sheet metal layout techniques by reading industry publications, attending trade shows and conferences, and participating in online forums and discussions. I am also actively involved in professional organizations, such as the Sheet Metal and Air Conditioning Contractors’ National Association (SMACNA), which provide opportunities for continuing education and networking with other professionals in the field.

7. What are the challenges of working as a Sheet Metal Layout Worker?

The challenges of working as a Sheet Metal Layout Worker include:

- Interpreting complex blueprints and technical drawings.

- Ensuring the accuracy and precision of layout patterns.

- Working with a variety of materials, including steel, aluminum, and stainless steel.

- Meeting tight deadlines.

- Working in a fast-paced and demanding environment.

8. What are the rewards of working as a Sheet Metal Layout Worker?

The rewards of working as a Sheet Metal Layout Worker include:

- Seeing your work come to life in the form of finished products.

- Knowing that you are playing a vital role in the construction or repair of buildings and other structures.

- Working with your hands and using your skills to create something tangible.

- Having the opportunity to learn and grow in a challenging and rewarding career.

9. What is your favorite part of working as a Sheet Metal Layout Worker?

My favorite part of working as a Sheet Metal Layout Worker is the challenge of creating accurate and efficient layout patterns. I enjoy using my skills to solve problems and find the best way to lay out a piece of sheet metal. It is also rewarding to see my work come to life in the form of finished products.

10. What are your career goals as a Sheet Metal Layout Worker?

My career goal is to become a highly skilled and experienced Sheet Metal Layout Worker. I want to continue to learn and grow in my profession, and I am eager to take on new challenges and responsibilities. I am also interested in becoming a mentor to other Sheet Metal Layout Workers and helping them to develop their skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Metal Layout Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Metal Layout Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet metal layout workers are highly skilled professionals responsible for marking and cutting metal sheets to specified dimensions and shapes. They use various tools and techniques to ensure precision and efficiency in their work. Their key responsibilities include:

1. Pattern Development

Develop patterns from engineering drawings or specifications using computer-aided design (CAD) software or manual methods.

2. Sheet Layout

Mark cutting lines, drill holes, and other details onto metal sheets using layout tools.

3. Sheet Cutting

Cut metal sheets according to the marked patterns using plasma cutters, laser cutters, or other cutting machines.

4. Quality Control

Measure and inspect cut sheets to ensure they meet specified tolerances and quality standards.

5. Material Handling

Load, unload, and move heavy metal sheets using hoists, forklifts, or manual labor.

6. Equipment Setup and Maintenance

Set up and maintain cutting equipment, including plasma cutters, laser cutters, and shears.

Interview Tips

To ace the interview for a Sheet Metal Layout Worker position, it’s crucial to prepare thoroughly and highlight your relevant skills and experience. Here are some tips to enhance your preparation:

1. Research the Company and Industry

Demonstrate your interest and knowledge of the company’s products, services, and industry trends. Research the specific job requirements and align your skills with them.

2. Practice Technical Skills

Review pattern development techniques, layout methods, and cutting equipment operation. Practice measuring, marking, and cutting metal sheets to demonstrate your proficiency.

3. Emphasize Safety Awareness

Highlight your understanding of safety protocols and regulations in a metalworking environment. Discuss your experience with proper handling of heavy materials, operating cutting machines, and maintaining a clean and safe workspace.

4. Showcase Attention to Detail

Emphasize your meticulous nature and attention to detail. Provide examples of your ability to follow complex instructions, meet tight tolerances, and ensure quality in your work.

5. Prepare for Behavioral Questions

Practice answering behavioral interview questions that assess your problem-solving skills, teamwork experience, and ability to work under pressure. Prepare specific examples that demonstrate your strengths in these areas.

Example Outline:

When answering behavioral interview questions, follow the STAR method:

- S (Situation): Describe the context or situation you were in.

- T (Task): Explain the specific task or challenge you faced.

- A (Action): Describe the actions you took to address the situation.

- R (Result): Discuss the outcome or results of your actions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sheet Metal Layout Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!