Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Sheet Metal Mechanic interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Sheet Metal Mechanic so you can tailor your answers to impress potential employers.

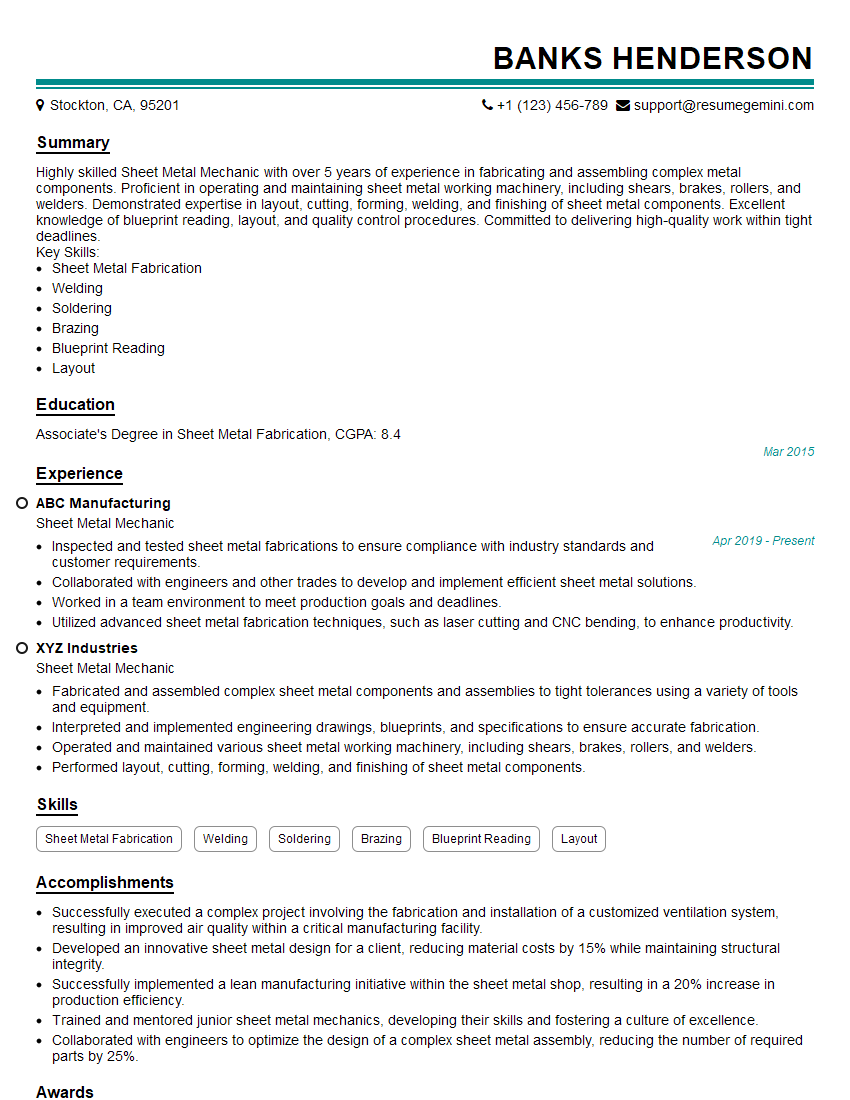

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Metal Mechanic

1. How would you measure and cut a piece of sheet metal to create a curved edge?

To create a curved edge on a piece of sheet metal, follow these steps:

- Determine the radius of the curve: Use a compass or measuring tape to determine the desired radius of the curve.

- Mark the center point: Locate the center point of the curve using a ruler or protractor.

- Draw a guide line: Using a compass or protractor, draw a guide line that represents the desired curve.

- Measure and cut: Measure and cut the sheet metal along the guide line, following the curve as closely as possible.

2. What are the different types of sheet metal brakes and how do they work?

Manual Brakes:

- Operate using a lever or foot pedal.

- Bend the metal by pressing it against a fixed beam.

Hydraulic Brakes:

- Use hydraulic pressure to apply force.

- Offer greater precision and bending capacity.

Pneumatic Brakes:

- Use compressed air to apply force.

- Provide faster bending speeds.

CNC Brakes:

- Computer-controlled for precise bending.

- Can handle complex bends and angles.

3. How do you calculate the bend allowance for a piece of sheet metal?

To calculate the bend allowance:

- Determine the material thickness: Measure the thickness of the sheet metal in millimeters (mm).

- Use the bend radius: Multiply the material thickness by the bend radius in millimeters (mm).

- Subtract the material thickness: Subtract the material thickness from the result obtained in step 2.

- Multiply by 2: Multiply the result obtained in step 3 by 2 to get the bend allowance in millimeters (mm).

4. What is the difference between shearing and punching?

- Shearing: A cutting process that uses a sharp blade to cut through sheet metal along a straight line.

- Punching: A process that uses a punch and die to create a hole in sheet metal.

5. How do you ensure the accuracy of your measurements and cuts when working with sheet metal?

To ensure accuracy:

- Use calibrated tools: Regularly calibrate measuring and cutting tools to ensure accuracy.

- Mark the metal clearly: Use a scribe or marker to mark cutting lines and bend lines precisely.

- Measure multiple times: Double-check measurements before cutting or bending to minimize errors.

- Use jigs and fixtures: Utilize jigs and fixtures to hold the metal in place and guide cuts or bends.

6. How do you handle scrap metal safely?

To handle scrap metal safely:

- Wear appropriate PPE: Wear gloves, safety glasses, and protective clothing.

- Store scrap properly: Keep scrap metal organized and contained in designated areas.

- Cut and dispose of sharp edges: Cut sharp edges off scrap metal before disposal.

- Follow environmental regulations: Comply with local regulations for scrap metal disposal.

7. What are the different types of welding processes used in sheet metal fabrication?

- MIG Welding: Uses a continuously fed wire electrode in a shielding gas atmosphere.

- TIG Welding: Uses a non-consumable tungsten electrode in a shielding gas atmosphere.

- Resistance Welding: Uses pressure and heat to join metal sheets without the use of filler metal.

- Spot Welding: Uses two electrodes to create localized welds.

8. Explain the process of forming a sheet metal part using a press brake.

The process involves:

- Loading the metal: Place the sheet metal between the press brake’s upper and lower dies.

- Positioning the dies: Adjust the dies to the desired bending angle.

- Bending the metal: Apply pressure to the upper die to bend the metal.

- Unloading the part: Remove the bent part from the press brake.

9. What are the common challenges faced in sheet metal fabrication and how do you overcome them?

- Distortion: Overcome by using proper clamping, supports, and annealing techniques.

- Springback: Compensate for springback by overbending or using specialized tooling.

- Accuracy: Achieve accuracy through precise measuring, careful setup, and using calibrated equipment.

- Surface finish: Ensure a good surface finish by selecting the right material, tooling, and finishing techniques.

10. Describe your experience in reading and interpreting engineering drawings.

In my previous role, I was responsible for reading and interpreting complex engineering drawings for a variety of sheet metal fabrication projects. I possess a strong understanding of drawing conventions, symbols, and dimensions. I am proficient in using CAD software to review and modify drawings as needed.

11. How do you stay updated on the latest advancements in sheet metal fabrication techniques?

I regularly attend industry conferences, workshops, and training programs to stay abreast of the latest advancements in sheet metal fabrication techniques. I also subscribe to trade publications, follow industry experts on social media, and engage in online forums to gather knowledge and connect with other professionals in the field.

12. Can you describe a time when you had to troubleshoot a problem with a sheet metal fabrication process?

During a recent project, we encountered an issue with excessive distortion in a complex sheet metal component. Through careful analysis of the process, I identified that the clamping pressure was insufficient. By adjusting the clamping system and using additional supports, I was able to eliminate the distortion and produce parts that met the required specifications.

13. What safety precautions do you take when working with sheet metal?

Safety is paramount in sheet metal fabrication. I always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and earplugs. I am aware of the potential hazards associated with sharp edges, machinery, and chemicals, and I take steps to minimize risks. I regularly inspect equipment, follow established safety procedures, and maintain a clean and organized work area.

14. How do you ensure the quality of your sheet metal products?

Quality assurance is essential in sheet metal fabrication. I follow established quality control procedures throughout the production process. I perform regular inspections at various stages to check for dimensional accuracy, surface finish, and overall workmanship. I also utilize measuring equipment and gauges to ensure that products meet the required specifications. By adhering to strict quality standards, I strive to deliver defect-free products to customers.

15. What are your career goals as a Sheet Metal Mechanic?

My career goal is to become a highly skilled and experienced Sheet Metal Mechanic. I am eager to expand my knowledge and expertise in the field, and I am particularly interested in exploring advanced fabrication techniques and new technologies. I am confident that my dedication to precision, quality, and safety will enable me to make significant contributions to the industry and achieve success in my chosen career path.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Metal Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Metal Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet Metal Mechanics play a vital role in manufacturing, construction, and maintenance industries by shaping and fabricating sheet metal components. Their key responsibilities include:1. Fabrication and Assembly

Fabricate sheet metal components from various materials such as aluminum, stainless steel, and galvanized steel using specialized tools and equipment.

- Use precision measuring instruments to ensure accuracy and meet specifications.

- Assemble sheet metal components by welding, riveting, or bolting to create complex structures.

2. Installation and Repair

Install and repair sheet metal products in buildings, vehicles, and equipment.

- Interpret blueprints and drawings to determine installation requirements.

- Inspect sheet metal components for defects and perform necessary repairs or replacements.

3. Maintenance

Maintain sheet metal installations and structures to ensure optimal performance and longevity.

- Inspect and clean sheet metal components regularly to prevent corrosion and other issues.

- Perform preventative maintenance checks and make adjustments as needed.

4. Quality Control

Ensure the quality of sheet metal products and installations through rigorous inspection.

- Verify dimensions, fit, and finish of sheet metal components using measuring tools and gauges.

- Identify and correct any defects or inconsistencies.

Interview Tips

To ace the interview for a Sheet Metal Mechanic position, candidates should prepare thoroughly. Here are some essential tips:1. Research the Company and the Industry

Learn about the company’s products, services, and culture. Understand the industry trends and advancements to demonstrate your knowledge and passion for the field.

- Visit the company’s website and social media profiles.

- Read industry publications and attend industry events.

2. Practice Your Technical Skills

Brush up on your technical skills in sheet metal fabrication, assembly, and installation. Ensure you are familiar with different materials, tools, and equipment.

- Review your experience in welding, riveting, and other sheet metal techniques.

- Practice reading and interpreting blueprints and drawings.

3. Emphasize Your Experience and Qualifications

Highlight your relevant work experience, skills, and certifications. Quantify your accomplishments and provide specific examples that demonstrate your abilities.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Provide examples of complex projects or challenges you have successfully overcome.

4. Be Professional and Enthusiastic

Dress professionally, arrive on time for your interview, and demonstrate a positive attitude. Show the interviewer that you are enthusiastic about the position and the company.

- Prepare thoughtful questions to ask the interviewer.

- Follow up after the interview to express your continued interest.

Next Step:

Now that you’re armed with the knowledge of Sheet Metal Mechanic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Sheet Metal Mechanic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini