Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sheet Metal Pattern Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

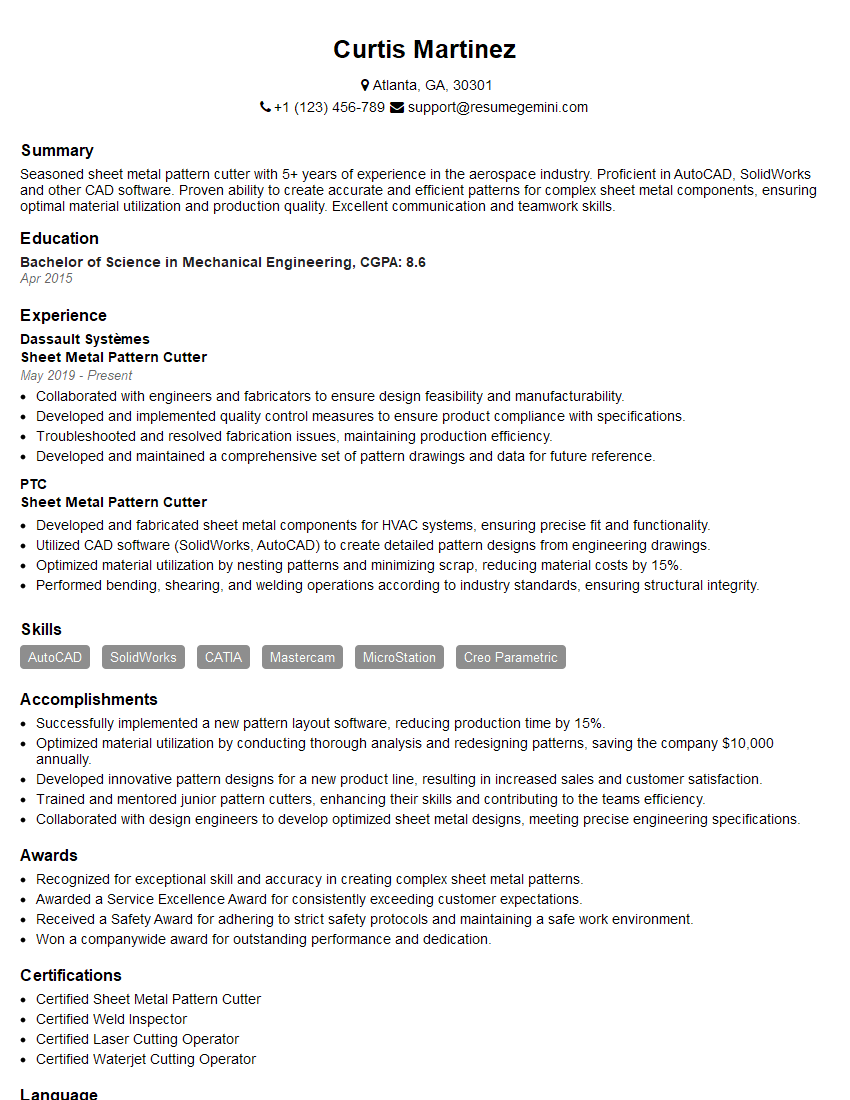

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Metal Pattern Cutter

1. Explain the types of sheet metal patterns you have created in the past?

In my previous role, I was responsible for creating a wide range of sheet metal patterns, including:

- Flat patterns: These are the most basic type of pattern, and they are used to create simple shapes, such as rectangles and circles.

- Developed patterns: These patterns are used to create more complex shapes, such as cones and cylinders.

- Compound patterns: These patterns are used to create shapes that are made up of multiple pieces, such as boxes and tanks.

2. What are the different materials you have worked with as Sheet Metal Pattern Cutter?

Metals:

- Steel: Stainless steel, Mild steel, Carbon steel

- Aluminium: Pure aluminium, Anodized aluminium

- Copper

- Brass

Non-Metals:

- Plastics: Acrylic, Polycarbonate, PVC

- Composite materials: Fiberglass, Carbon fiber

3. How do you ensure the accuracy of your patterns before they go into production?

I use a variety of methods to ensure the accuracy of my patterns before they go into production, including:

- Checking all dimensions carefully.

- Using a CAD program to create the patterns.

- Making a prototype of the pattern to test its accuracy.

4. What is the most challenging pattern you have ever created?

The most challenging pattern I have ever created was a pattern for a complex duct system. The duct system had a number of bends and offsets, and it was important to ensure that the pattern was accurate so that the duct system would fit together properly.

5. What is your experience with using different sheet metal fabrication techniques?

I have experience with a variety of sheet metal fabrication techniques, including:

- Cutting

- Bending

- Welding

- Finishing

6. What are the key considerations when developing a sheet metal pattern?

The key considerations when developing a sheet metal pattern include:

- The type of material being used.

- The thickness of the material.

- The shape of the part being created.

- The bends and flanges that are required.

- The manufacturing process that will be used.

7. What are the common mistakes that sheet metal pattern cutters make?

Some of the common mistakes that sheet metal pattern cutters make include:

- Not taking into account the thickness of the material.

- Not allowing for bends and flanges.

- Not using the correct manufacturing process.

- Not checking the accuracy of the pattern before it goes into production.

8. How do you handle the scrap produced during the sheet metal fabrication process?

I typically handle the scrap produced during the sheet metal fabrication process by:

- Sorting the scrap by material type.

- Recycling the scrap metal.

- Donating the scrap metal to a local charity.

9. What are the latest trends in sheet metal fabrication technology?

Some of the latest trends in sheet metal fabrication technology include:

- The use of lasers for cutting and welding.

- The use of robots for automation.

- The use of 3D printing for prototyping.

10. How do you stay up-to-date on the latest trends in sheet metal fabrication technology?

I stay up-to-date on the latest trends in sheet metal fabrication technology by:

- Reading trade publications.

- Attending industry events.

- Taking online courses.

11. What is the most important thing you have learned in your career as a sheet metal pattern cutter?

The most important thing I have learned in my career as a sheet metal pattern cutter is the importance of accuracy. A small error in a pattern can lead to a big problem in the finished product. That’s why it’s so important to take your time and check your work carefully.

12. What are your strengths as a sheet metal pattern cutter?

My strengths as a sheet metal pattern cutter include:

- My attention to detail.

- My ability to visualize 3D objects.

- My knowledge of sheet metal fabrication techniques.

- My experience with a variety of materials.

13. What are your weaknesses as a sheet metal pattern cutter?

My weaknesses as a sheet metal pattern cutter include:

- I can be slow at times, especially when working on complex patterns.

- I am not always the best at communicating my ideas to others.

14. What are your goals for your career as a sheet metal pattern cutter?

My goals for my career as a sheet metal pattern cutter are to:

- Become a master pattern cutter.

- Start my own sheet metal fabrication business.

- Teach sheet metal pattern cutting.

15. What is your salary expectation?

My salary expectation is $60,000 per year.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Metal Pattern Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Metal Pattern Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet Metal Pattern Cutters play a vital role in the manufacturing industry, utilizing their expertise in creating patterns and templates for sheet metal components. These highly skilled professionals contribute to various aspects of metal fabrication and work closely with engineers, designers, and other team members to ensure the precise production of sheet metal parts.

1. Pattern Development

The primary responsibility of Sheet Metal Pattern Cutters is to develop and create patterns for sheet metal components. They use specialized techniques and knowledge to transform design specifications and drawings into accurate patterns. These patterns serve as templates for cutting and shaping the sheet metal, ensuring the desired dimensions and contours.

- Analyze engineering drawings and specifications to understand the design intent.

- Use computer-aided design (CAD) software to create flat patterns and nesting layouts.

- Consider factors such as material properties, thickness, and grain direction when developing patterns.

2. Material Selection and Estimation

Sheet Metal Pattern Cutters also play a role in selecting and estimating the required sheet metal materials. They determine the appropriate type, thickness, and quantity of sheet metal based on the design requirements and functional specifications.

- Understand different types of sheet metal materials, their properties, and applications.

- Estimate the quantity and cost of materials needed for production.

- Recommend material alternatives or suggest modifications to optimize material usage.

3. Production Support

Sheet Metal Pattern Cutters provide support and guidance to the production team throughout the manufacturing process. They review and approve work orders, ensuring that the patterns and templates are accurate and complete.

- Work closely with fabricators and operators to translate patterns into finished parts.

- Inspect and verify the quality of produced components against the original design specifications.

- Troubleshoot any issues related to pattern accuracy or production defects.

4. Continuous Improvement

Sheet Metal Pattern Cutters are committed to continuous improvement and innovation in their field. They stay updated on industry best practices, new technologies, and materials to enhance their skills and contribute to the overall efficiency of the manufacturing process.

- Participate in training and workshops to develop new skills and knowledge.

- Explore new methods and techniques to improve pattern development and optimization.

- Collaborate with engineers and designers to identify areas for process improvement.

Interview Tips

Preparing for a Sheet Metal Pattern Cutter interview requires thorough research and practice. Here are some essential tips to help candidates ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and industry standing. Research the specific job requirements and responsibilities to demonstrate your understanding of the role.

- Visit the company’s website and social media pages.

- Read industry-related articles and publications to gain insights into current trends.

2. Practice Your Skills and Knowledge

Review your technical skills in pattern development, material selection, and production support. Practice solving problems and explaining your thought process to showcase your expertise.

- Create a portfolio of your previous work or provide examples of projects you have undertaken.

- Brush up on your knowledge of sheet metal materials, properties, and fabrication techniques.

3. Prepare for Behavioral Questions

Interviewers often ask behavioral questions to assess your problem-solving abilities, teamwork skills, and work ethic. Prepare for these questions by reflecting on your past experiences and identifying relevant examples.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Highlight your strengths and how they align with the job requirements.

4. Ask Thoughtful Questions

Preparing thoughtful questions for the interviewer demonstrates your interest and engagement. Ask questions that delve deeper into the company culture, the role’s responsibilities, or the industry outlook.

- Inquire about the company’s investment in technology and innovation.

- Ask about the opportunities for professional development and growth.

5. Be Professional and Confident

Dress appropriately, arrive on time, and maintain a positive and professional demeanor throughout the interview. Confidence in your abilities and enthusiasm for the role will make a lasting impression.

- Practice your handshake and make eye contact with the interviewer.

- Speak clearly and articulate your thoughts effectively.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Sheet Metal Pattern Cutter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Sheet Metal Pattern Cutter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.