Are you gearing up for an interview for a Sheet Metal Smith position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Sheet Metal Smith and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

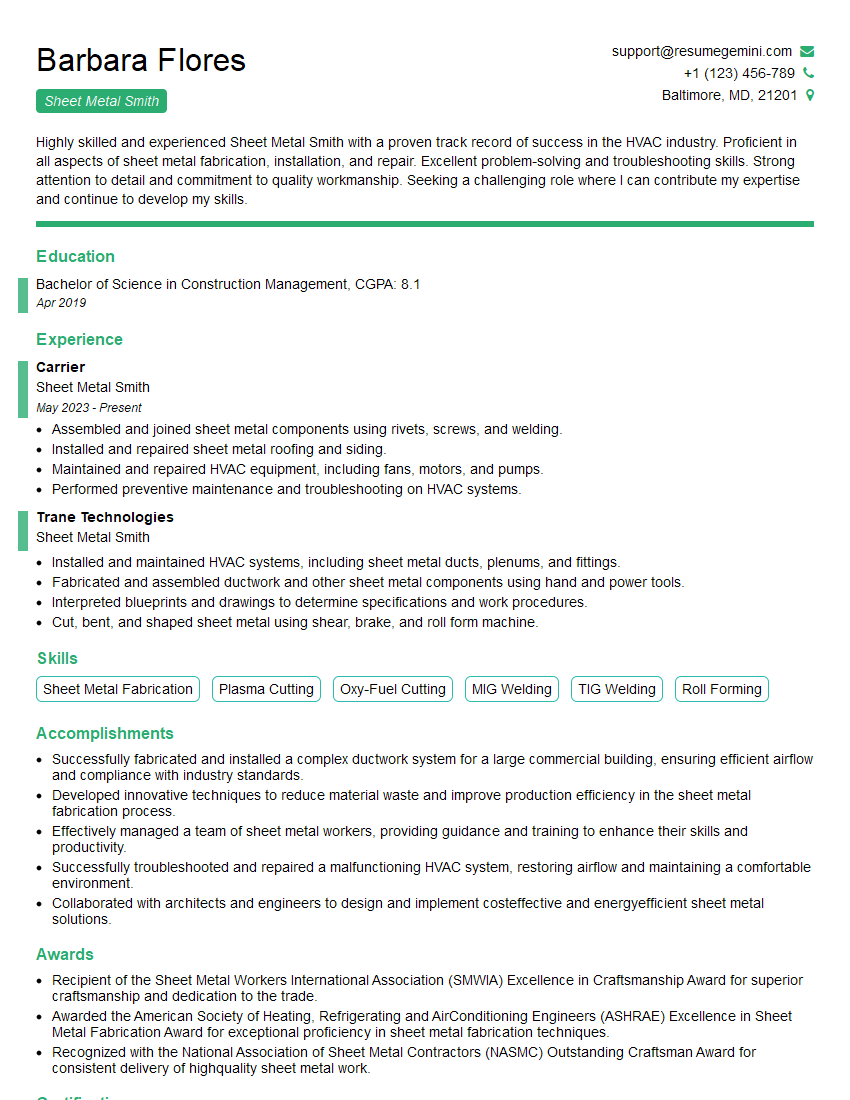

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Metal Smith

1. What are the different types of sheet metal forming processes?

- Bending

- Folding

- Rolling

- Stamping

2. What are the different types of sheet metal bending brakes?

- Manual benders

- Hydraulic benders

- CNC benders

3. How do you ensure the accuracy of sheet metal bends?

- Use the proper tooling

- Set the correct bend angle

- Use a back gauge to ensure the correct bend location

4. What are the different types of sheet metal welding processes?

- MIG welding

- TIG welding

- Arc welding

5. How do you weld sheet metal without warping it?

- Use a tack weld to hold the pieces in place

- Use short, intermittent welds

- Allow the metal to cool between welds

6. How do you calculate the bend allowance for a sheet metal bend?

- Use the formula: BA = (π x D) / 180, where BA is the bend allowance, D is the diameter of the bend, and π is the mathematical constant approximately equal to 3.14

7. What is the difference between a flange and a hem?

- A flange is a bent edge that is used to join two pieces of sheet metal.

- A hem is a bent edge that is used to finish the edge of a piece of sheet metal.

8. What is the importance of grain direction when forming sheet metal?

- The grain direction of the sheet metal affects its strength and ductility.

- When forming sheet metal, it is important to orient the grain direction in the direction of the bend to avoid cracking.

9. What are the different types of sheet metal finishes?

- Painted finishes

- Anodized finishes

- Powder-coated finishes

10. What are the safety precautions that must be taken when working with sheet metal?

- Wear gloves to protect your hands from sharp edges.

- Wear safety glasses to protect your eyes from flying debris.

- Use caution when operating machinery.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Metal Smith.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Metal Smith‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet Metal Smiths are responsible for fabricating and installing sheet metal products. These products can include anything from ductwork and roofing to siding and gutters.

1. Fabrication

Sheet Metal Smiths use a variety of tools and equipment to fabricate sheet metal products. These tools include shears, brakes, rolls, and welders. Smiths must be able to read and interpret blueprints and drawings in order to create accurate products.

- Read and interpret blueprints and drawings

- Operate a variety of tools and equipment, including shears, brakes, rolls, and welders

- Fabricate sheet metal products according to specifications

2. Installation

Sheet Metal Smiths also install sheet metal products. This process involves measuring, cutting, and fitting the product to the desired location. Smiths must be able to work safely at heights and in confined spaces.

- Install sheet metal products according to specifications

- Measure, cut, and fit sheet metal products

- Work safely at heights and in confined spaces

3. Maintenance

Sheet Metal Smiths also perform maintenance on sheet metal products. This process involves inspecting the products for damage and repairing or replacing any damaged parts.

- Inspect sheet metal products for damage

- Repair or replace damaged parts

- Maintain sheet metal products in good working condition

4. Other Duties

In addition to the above responsibilities, Sheet Metal Smiths may also be required to perform other duties, such as:

- Estimate the cost of sheet metal projects

- Order materials and supplies

- Train and supervise apprentices

Interview Tips

Preparing for a Sheet Metal Smith interview can help you make a great impression on the hiring manager and increase your chances of getting the job. Here are a few tips to help you prepare:

1. Research the company

Before you go to your interview, take some time to research the company. This will help you understand the company’s culture and values, and it will also give you a better idea of the specific job requirements.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this job?” Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Bring a portfolio of your work

If you have any examples of your work, be sure to bring them to your interview. This will give the hiring manager a chance to see your skills and craftsmanship firsthand.

4. Be prepared to talk about your safety experience

Sheet Metal Smiths work in a variety of hazardous environments, so it is important to be prepared to talk about your safety experience. Be sure to highlight any safety training or certifications that you have.

5. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or other business attire. You should also make sure that your clothes are clean and pressed.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Sheet Metal Smith role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.