Feeling lost in a sea of interview questions? Landed that dream interview for Sheet Metal Welder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Sheet Metal Welder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

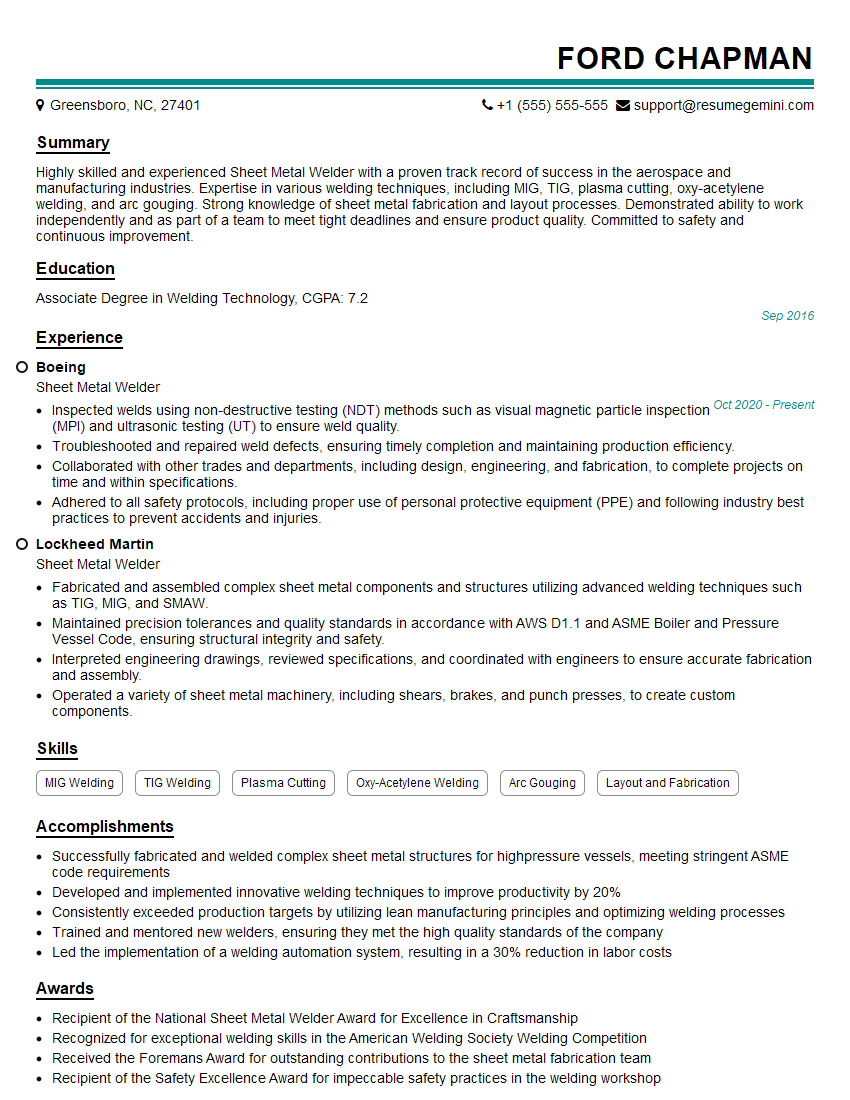

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Metal Welder

1. What are the common types of sheet metal welding joints?

- Butt joint: Two pieces of metal are joined together edge-to-edge.

- Edge joint: Two pieces of metal are joined together along their edges.

- Corner joint: Two pieces of metal are joined together at a 90-degree angle.

- T-joint: A piece of metal is joined to another piece of metal at a right angle.

- Lap joint: Two pieces of metal overlap and are joined together.

2. What are the different welding processes used for sheet metal?

MIG welding

- Uses a continuous wire electrode that is fed into the weld pool.

- Produces a clean, high-quality weld.

- Is relatively fast and easy to learn.

TIG welding

- Uses a non-consumable tungsten electrode to create an arc that melts the metal.

- Produces a very precise, high-quality weld.

- Is more difficult to learn than MIG welding.

3. What are the safety precautions that must be taken when welding sheet metal?

- Wear appropriate protective clothing, including a welding helmet, gloves, and apron.

- Ensure that the welding area is well-ventilated.

- Keep flammable materials away from the welding area.

- Never weld on or near energized electrical equipment.

- Be aware of the fire hazards associated with welding.

4. What are the typical welding defects that can occur when welding sheet metal?

- Porosity: Small holes in the weld caused by trapped gas.

- Lack of fusion: The weld metal does not properly bond to the base metal.

- Undercut: The weld metal cuts into the base metal.

- Cold lap: A weld that is not properly fused because the metal was too cold when it was joined.

- Overheating: The weld metal is heated to too high a temperature, causing it to become brittle.

5. How do you determine the correct welding parameters for sheet metal?

- Consider the thickness of the metal.

- Select the appropriate welding process.

- Choose the correct electrode size and type.

- Set the welding machine to the proper voltage and amperage.

- Test the weld on a scrap piece of metal before welding the actual workpiece.

6. What are the different types of welding equipment used for sheet metal?

- Welding machines: MIG welders, TIG welders, etc.

- Electrodes: Consumable and non-consumable.

- Shielding gases: Argon, helium, etc.

- Welding torches: Hand-held and machine-mounted.

- Welding tables: Provide a stable surface for welding.

7. How do you maintain and calibrate welding equipment?

- Clean the welding equipment regularly.

- Inspect the welding equipment for damage.

- Calibrate the welding equipment according to the manufacturer’s instructions.

- Keep a maintenance log to track the equipment’s performance.

- Follow all safety precautions when maintaining and calibrating welding equipment.

8. What are the different types of welding joints used for sheet metal fabrication?

- Butt joints: Used to join two pieces of metal together edge-to-edge.

- Edge joints: Used to join two pieces of metal together along their edges.

- Corner joints: Used to join two pieces of metal together at a 90-degree angle.

- T-joints: Used to join a piece of metal to another piece of metal at a right angle.

- Lap joints: Used to join two pieces of metal together by overlapping them.

9. What are the factors that affect the quality of a welded joint?

- Welding process used

- Welding parameters

- Material thickness

- Joint design

- Welding operator skill

10. What are the common welding defects and how can they be prevented?

- Porosity: Caused by trapped gases in the weld metal. Can be prevented by using a clean welding surface and shielding gas.

- Lack of fusion: Occurs when the weld metal does not properly fuse to the base metal. Can be prevented by using sufficient heat and pressure during welding.

- Undercut: A groove that is formed in the base metal next to the weld. Can be prevented by using the correct welding parameters and technique.

- Cold lap: A defect that occurs when the weld metal is not properly fused together. Can be prevented by using sufficient heat and pressure during welding.

- Overheating: Occurs when the weld metal is heated to too high a temperature. Can be prevented by using the correct welding parameters and technique.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Metal Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Metal Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet Metal Welders play a vital role in various industries, specializing in joining sheet metal components by employing various welding techniques. Their key responsibilities encompass:

1. Safety and Compliance

Adhering to all safety regulations and industry standards to ensure a safe and hazard-free work environment.

- Wearing appropriate personal protective equipment (PPE)

- Maintaining a clean and organized workspace

2. Welding and Fabrication

Skilled in operating different welding equipment and techniques to fabricate and repair sheet metal components.

- Interpreting blueprints and specifications

- Cutting, shaping, and joining sheet metal using welding torches

3. Quality Control

Ensuring the quality and precision of welded joints by conducting regular inspections and adhering to quality standards.

- Testing welds for strength and integrity

- Inspecting finished products for accuracy and defects

4. Maintenance and Repair

Performing maintenance and repairs on welding equipment, ensuring it operates efficiently and safely.

- Troubleshooting and resolving equipment issues

- Inspecting and replacing worn or damaged parts

Interview Tips

To ace the Sheet Metal Welder interview, consider the following tips:

1. Research and Preparation

Thoroughly research the company, industry, and specific job requirements to demonstrate your knowledge and interest.

- Review company website and industry news

- Prepare specific questions to ask the interviewer

2. Highlight Your Skills

Emphasize your proficiency in various welding techniques, including MIG, TIG, and arc welding.

- Provide examples of complex welding projects you have completed

- Quantify your accomplishments by providing specific metrics

3. Safety and Quality

Stress your commitment to safety and maintaining high-quality standards.

- Highlight your understanding of welding safety regulations

- Explain your quality control process and adherence to industry standards

4. Culture Fit

Demonstrate your enthusiasm for the industry and willingness to contribute to the team’s success.

- Research the company’s culture and values

- Explain how your skills and experience align with the company’s needs

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Sheet Metal Welder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.