Feeling lost in a sea of interview questions? Landed that dream interview for Sheet Metal Worker Helper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Sheet Metal Worker Helper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

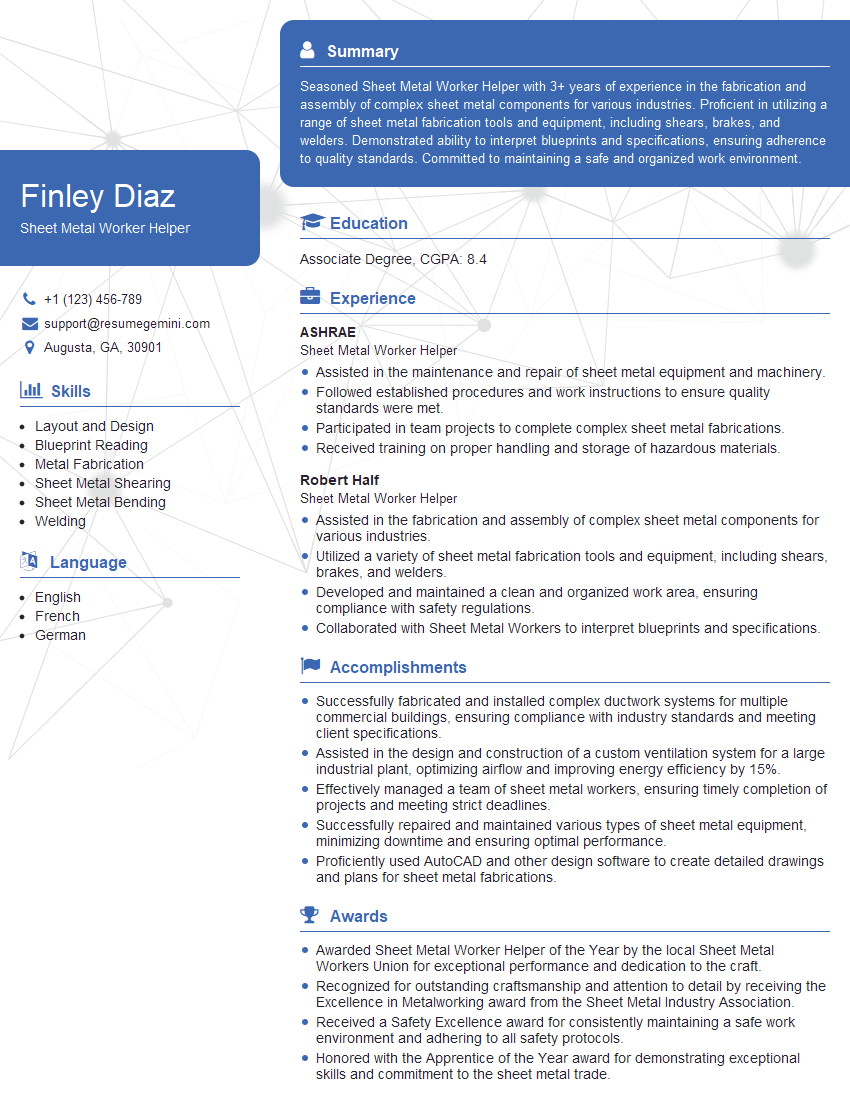

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Metal Worker Helper

1. Can you describe the process of cutting sheet metal using a shear?

In the process of cutting sheet metal using a shear, the metal is placed between the two blades of the shear. The upper blade is then forced down onto the lower blade, cutting through the metal. The amount of force required to cut through the metal will depend on the thickness and hardness of the metal.

- Ensure the shear is properly calibrated and sharp.

- Position the sheet metal correctly on the shear bed.

- Apply appropriate pressure on the foot pedal to activate the cutting action.

- Control the cutting speed to achieve clean and precise edges.

2. What are the different types of sheet metal brakes and their applications?

Mechanical Brakes

- Manually operated using a lever or foot pedal.

- Suitable for bending small to medium-sized sheet metal pieces.

Hydraulic Brakes

- Powered by hydraulic pressure, offering greater bending force.

- Ideal for bending thicker or larger sheet metal components.

CNC Brakes

- Computer-controlled, allowing for precise and complex bends.

- Capable of bending various materials, including sheet metal, aluminum, and stainless steel.

3. How do you measure and transfer angles accurately when working with sheet metal?

To accurately measure and transfer angles when working with sheet metal, the following steps can be followed:

- Use a protractor or angle finder to measure the desired angle.

- Mark the angle on the sheet metal using a pencil or scribe.

- Transfer the angle to the desired location using a transfer punch or dividers.

- Re-check the angle using a protractor to ensure accuracy.

4. What techniques do you use to form and shape sheet metal?

Various techniques can be employed to form and shape sheet metal, including:

- Bending: Using a brake to create angles and bends.

- Rolling: Passing the sheet metal through rollers to create curves and cylinders.

- Stretching: Stretching the metal over a form to achieve desired shapes.

- Shrinking: Applying heat to reduce the size of the metal.

5. Can you explain the different types of welding processes used in sheet metal fabrication?

In sheet metal fabrication, the following welding processes are commonly used:

- MIG (Metal Inert Gas) Welding: Uses a continuously fed wire electrode and inert gas to protect the weld area.

- TIG (Tungsten Inert Gas) Welding: Employs a non-consumable tungsten electrode and inert gas to create precise and high-quality welds.

- Spot Welding: Uses two electrodes to apply localized heat and pressure, creating strong spot welds.

- Resistance Welding: Joins metal sheets by applying pressure and electric current, causing them to fuse together.

6. How do you ensure the quality of welds in sheet metal fabrication?

Quality assurance in sheet metal welding involves the following steps:

- Proper Preparation: Clean and prepare the metal surfaces before welding.

- Correct Welding Parameters: Set the appropriate voltage, amperage, and travel speed.

- Visual Inspection: Examine the welds for any visible defects or imperfections.

- Non-Destructive Testing: Use methods like dye penetrant or ultrasonic testing to detect internal flaws.

7. What is the importance of safety protocols in sheet metal fabrication?

Safety protocols are crucial in sheet metal fabrication to prevent accidents and maintain a safe work environment. These protocols include:

- Proper PPE: Wearing appropriate personal protective equipment, such as gloves, safety glasses, and respirators.

- Guarding Machinery: Ensuring machines have proper guards and safety devices.

- Fire Prevention: Taking precautions to prevent and control fires, such as having fire extinguishers readily available.

- Ventilation: Maintaining proper ventilation to remove fumes and dust.

8. Can you describe the process of creating a sheet metal duct system?

Creating a sheet metal duct system involves the following steps:

- Design: Designing the duct system based on airflow requirements and space constraints.

- Sheet Metal Preparation: Cutting and forming the sheet metal to the desired shapes and dimensions.

- Assembly: Joining the sheet metal components together using welding, riveting, or seaming techniques.

- Testing: Conducting pressure and airflow tests to ensure proper functioning.

9. What are the key considerations when selecting sheet metal for a fabrication project?

When selecting sheet metal for a fabrication project, the following factors should be considered:

- Material Properties: Strength, durability, corrosion resistance, and formability of the metal.

- Thickness: Choosing the appropriate thickness based on the structural requirements and load-bearing capacity.

- Surface Finish: Selecting a finish that meets the aesthetic and functional needs of the project.

- Cost and Availability: Considering the budget and accessibility of the desired sheet metal type.

10. How do you stay up-to-date with the latest advancements and techniques in sheet metal fabrication?

To stay up-to-date with the latest advancements and techniques in sheet metal fabrication, I engage in the following practices:

- Trade Shows and Conferences: Attending industry events to learn about new technologies and best practices.

- Training Programs: Participating in workshops and courses to enhance my skills and knowledge.

- Online Resources: Utilizing websites, forums, and social media to access up-to-date information and connect with industry professionals.

- Industry Publications: Subscribing to magazines and journals to stay informed about the latest trends and developments.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Metal Worker Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Metal Worker Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet Metal Worker Helpers play a vital role in supporting fabricating, installing, and maintaining sheet metal products. Their responsibilities encompass a wide range of tasks, ensuring smooth production processes and high-quality results.

1. Assisting in Fabrication

Helpers assist Sheet Metal Workers in cutting, bending, welding, and finishing sheet metal. They follow designated patterns and instructions, using appropriate tools and machinery.

- Assist in cutting metal using shears, nibblers, or plasma cutters.

- Help bend and form metal using press brakes, rolls, or hammers.

2. Material Handling and Setup

Helpers are responsible for handling and moving materials, ensuring they are available for fabrication. They also assist in setting up and maintaining equipment.

- Unload and load materials from trucks, racks, and workbenches.

- Help set up and adjust machinery, ensuring proper alignment and functionality.

3. Cleaning and Maintenance

Helpers contribute to the upkeep of the work area, tools, and equipment. They perform cleaning, maintenance, and minor repairs as needed.

- Clean and maintain workbenches, tools, and equipment to ensure optimal performance.

- Inspect and lubricate equipment, reporting any issues to the supervisor.

4. Safety and Compliance

Helpers understand and adhere to safety regulations and procedures. They wear appropriate safety gear and follow established guidelines to prevent accidents.

- Wear safety gear such as gloves, goggles, and hard hats to protect against hazards.

- Follow established safety protocols, including proper lifting techniques and lockout/tagout procedures.

Interview Tips

To ace the interview for a Sheet Metal Worker Helper position, it’s essential to prepare effectively. Here are some valuable tips and hacks to help you navigate the interview process:

1. Research the Company and Industry

Before the interview, take time to learn about the company’s background, products, services, and industry trends. This demonstrates your interest and enthusiasm for the role.

- Visit the company’s website to gather information about their history, mission, and recent developments.

- Research industry-specific publications and news articles to stay up-to-date with the latest advancements in sheet metal fabrication.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers. This allows you to organize your thoughts and articulate your skills and experiences.

- Brainstorm potential questions related to your abilities, such as: “Tell me about your experience in material handling.” or “How do you ensure safety in the workplace?”

- Craft concise and specific answers that highlight your relevant skills and demonstrate your understanding of the job responsibilities.

3. Highlight Your Skills and Experience

Emphasize your skills and experience that are directly applicable to the job requirements. Quantify your accomplishments whenever possible to demonstrate your value.

- If you have experience in handling large materials, mention the weight or volume of the materials you’ve worked with.

- Discuss your knowledge of safety regulations and provide examples of how you’ve applied them in previous roles.

4. Ask Thoughtful Questions

Prepare thoughtful questions to ask the interviewer about the company, the role, and their expectations. This shows your engagement and interest in the position.

- Ask about the company’s growth plans, their commitment to safety, or their investment in training and development.

- Inquire about the opportunities for career advancement within the organization.

5. Show Enthusiasm and Professionalism

Throughout the interview, maintain a positive and enthusiastic attitude. Dress appropriately, arrive on time, and be respectful of the interviewer’s time.

- Smile, make eye contact, and shake hands firmly.

- Listen attentively to the interviewer’s questions and respond clearly and concisely.

- Thank the interviewer for their time and express your appreciation for the opportunity to interview for the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sheet Metal Worker Helper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.