Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sheet Mill Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

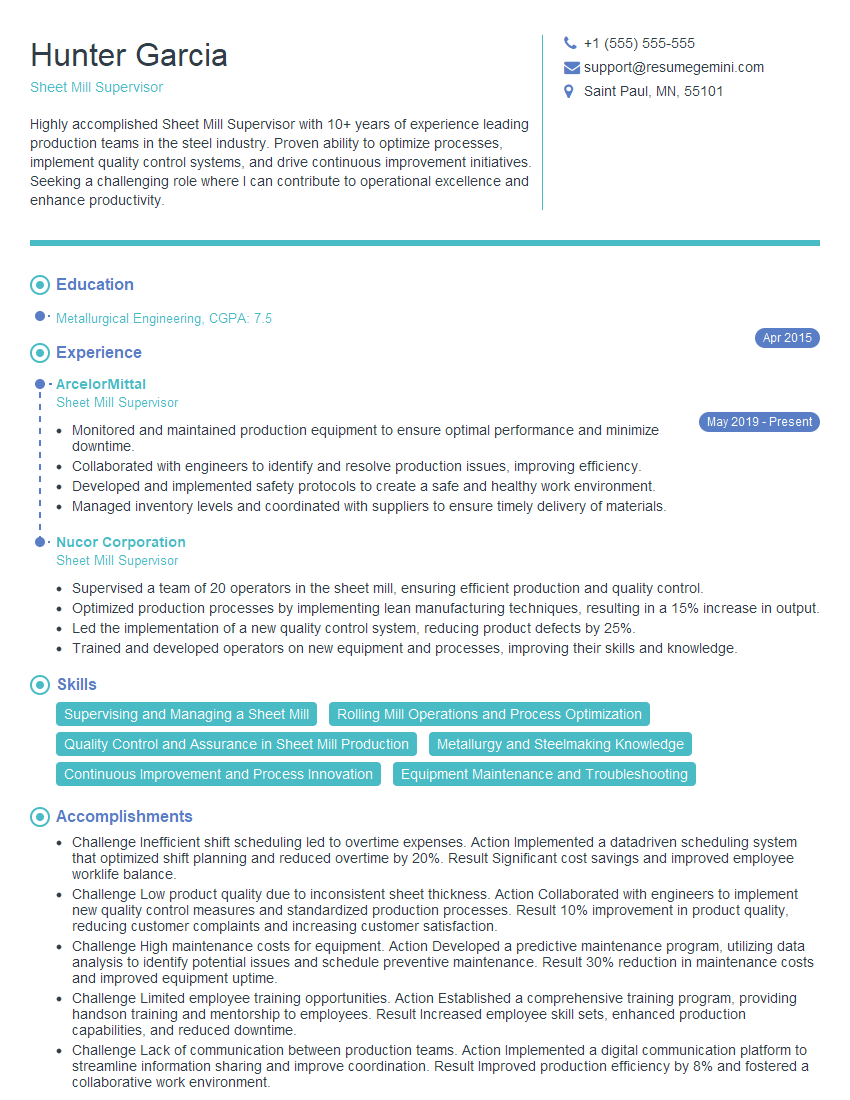

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Mill Supervisor

1. Describe the cold rolling process and the key parameters that affect the final product quality?

- Cold rolling is a metalworking process that involves passing a metal sheet through a series of rollers to reduce its thickness and improve its surface finish.

- The key parameters that affect the final product quality include:

- Roll gap: The distance between the rollers.

- Rolling speed: The speed at which the metal sheet passes through the rollers.

- Rolling force: The force applied to the metal sheet by the rollers.

- Lubrication: The type and amount of lubricant used.

- Material properties: The properties of the metal sheet being rolled, such as its strength, hardness, and ductility.

2. How do you ensure that the sheet mill is operating at peak efficiency and minimizing downtime?

Equipment Maintenance Schedule

- Establish a proactive maintenance schedule to regularly inspect, clean, and lubricate equipment.

- Identify and replace worn or damaged parts promptly to prevent breakdowns.

Operator Training

- Provide comprehensive training to operators on proper equipment operation and troubleshooting.

- Empower operators to identify and resolve minor issues, reducing the need for external maintenance.

Real-time Monitoring

- Implement real-time monitoring systems to track key performance indicators, such as machine temperature, vibration, and output.

- Use this data to identify potential problems early on and take preventive measures.

Production Optimization

- Analyze production data to identify bottlenecks and areas for improvement.

- Optimize process parameters and scheduling to maximize throughput while maintaining quality.

3. What are the common defects that can occur during sheet rolling and how do you prevent them?

- Edge cracks: Caused by excessive tension or uneven rolling. Prevented by proper roll setup and lubrication.

- Center buckles: Caused by uneven rolling or improper material handling. Prevented by maintaining proper roll gap and tension control.

- Surface scratches: Caused by foreign objects or improper handling. Prevented by keeping the mill clean and using proper handling techniques.

- Roll marks: Caused by worn or damaged rolls. Prevented by regular roll maintenance and replacement.

- Wavy edges: Caused by uneven heating or cooling. Prevented by proper temperature control and annealing processes.

4. How do you manage a team of operators and ensure that they are meeting performance targets?

- Clear Communication: Establish clear performance targets and expectations.

- Regular Feedback: Provide regular feedback to operators on their performance, both positive and constructive.

- Training and Development: Offer opportunities for training and development to enhance operators’ skills and knowledge.

- Empowerment: Empower operators to make decisions and take ownership of their work.

- Recognition and Rewards: Recognize and reward operators for their efforts and achievements.

5. Describe a time when you had to troubleshoot a complex problem on the sheet mill and how you resolved it?

Problem: Excessive scrap due to edge cracks during cold rolling.

Troubleshooting Steps:

- Inspected the rolls for wear and damage.

- Checked the roll gap and tension settings.

- Analyzed the material properties and lubrication used.

Resolution:

- Replaced worn rolls.

- Adjusted the roll gap and tension to reduce stress on the edges.

- Switched to a different lubricant with better edge protection.

- The problem was resolved, resulting in a significant reduction in scrap and improved product quality.

6. What are your strategies for reducing waste and improving sustainability in the sheet mill?

- Material Optimization: Implement techniques to minimize material waste, such as yield management and scrap reduction programs.

- Energy Efficiency: Optimize energy consumption through measures like equipment upgrades, process improvements, and waste heat recovery.

- Water Conservation: Implement water-saving practices, such as closed-loop cooling systems and rainwater harvesting.

- Waste Management: Establish effective waste management systems for scrap, lubricants, and other materials to reduce environmental impact.

- Employee Engagement: Engage employees in sustainability initiatives to foster a culture of waste reduction and environmental stewardship.

7. How do you stay up-to-date with the latest technologies and best practices in sheet rolling?

- Attend industry conferences and exhibitions.

- Read technical journals and articles.

- Network with other professionals in the field.

- Participate in online forums and webinars.

- Seek opportunities for professional development and training.

8. What are your strengths and weaknesses as a Sheet Mill Supervisor?

Strengths

- Expertise in sheet rolling processes and equipment.

- Strong leadership and management skills.

- Ability to troubleshoot and resolve complex technical issues.

- Excellent communication and interpersonal skills.

- Commitment to safety and quality.

Weaknesses

- Limited experience with certain specialized rolling techniques.

- Working independently for extended periods.

9. Why are you interested in this position?

- Excited about the opportunity to contribute to a leading sheet mill operation.

- Passionate about improving efficiency and product quality.

- Interested in developing my skills and taking on new challenges.

- Confident in my abilities to lead and motivate a team.

- Eager to make a positive impact on the industry.

10. What are your salary expectations?

My salary expectations are aligned with the industry standards for a Sheet Mill Supervisor with my experience and qualifications. I am open to discussing a competitive salary package that is commensurate with the responsibilities of the role and the company’s compensation structure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Mill Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Mill Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet Mill Supervisors oversee the production of sheet metal products in a rolling mill facility. They play a pivotal role in ensuring efficient operations, maintaining equipment, and guaranteeing the quality of finished products.

1. Production Management

Supervisors coordinate and monitor all aspects of sheet metal production, from raw material acquisition to finished product storage.

- Plan and schedule production runs to optimize efficiency and meet demand.

- Monitor production progress and identify potential bottlenecks or delays.

2. Equipment Maintenance

Supervisors are responsible for the upkeep and repair of all rolling mill equipment.

- Conduct regular inspections and preventive maintenance to minimize downtime.

- Supervise repairs and ensure equipment is operating safely and efficiently.

3. Quality Control

Supervisors ensure that sheet metal products meet specifications and customer requirements.

- Establish and implement quality control standards.

- Monitor production processes to identify and correct defects.

4. Workforce Management

Supervisors lead and motivate a team of operators and technicians.

- Assign tasks, provide training, and evaluate performance.

- Create a positive work environment and foster teamwork.

Interview Tips

Preparing for a Sheet Mill Supervisor interview requires thorough research and practice. Here are some interview preparation tips that can help you ace the interview:

1. Research the Company and Industry

Understand the company’s history, product line, and market position. Research the rolling mill industry and recent trends.

- Visit the company website, read industry publications, and network with professionals.

- Be prepared to discuss how your skills and experience align with the company’s needs.

2. Prepare for Technical Questions

Expect questions about rolling mill operations, equipment maintenance, and quality control processes.

- Review basic rolling mill principles and equipment.

- Think of past projects or experiences that demonstrate your technical expertise.

3. Highlight Your Leadership and Management Skills

Emphasize your ability to lead, motivate, and manage a team. Provide specific examples of situations where you have successfully led or managed projects.

- Describe how you have handled employee performance issues or resolved conflicts.

- Explain how you prioritize tasks, manage workflow, and delegate responsibilities.

4. Practice Your Answers

Prepare concise and thoughtful answers to common interview questions. Practice delivering your answers clearly and confidently.

- Conduct mock interviews with friends or colleagues to receive feedback.

- Record yourself answering interview questions to identify areas for improvement.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately for the interview and arrive on time.

- Consider wearing a business suit or tailored dress.

- Be mindful of your grooming and accessories.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sheet Mill Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!