Are you gearing up for an interview for a Sheet Rock Finisher position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Sheet Rock Finisher and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

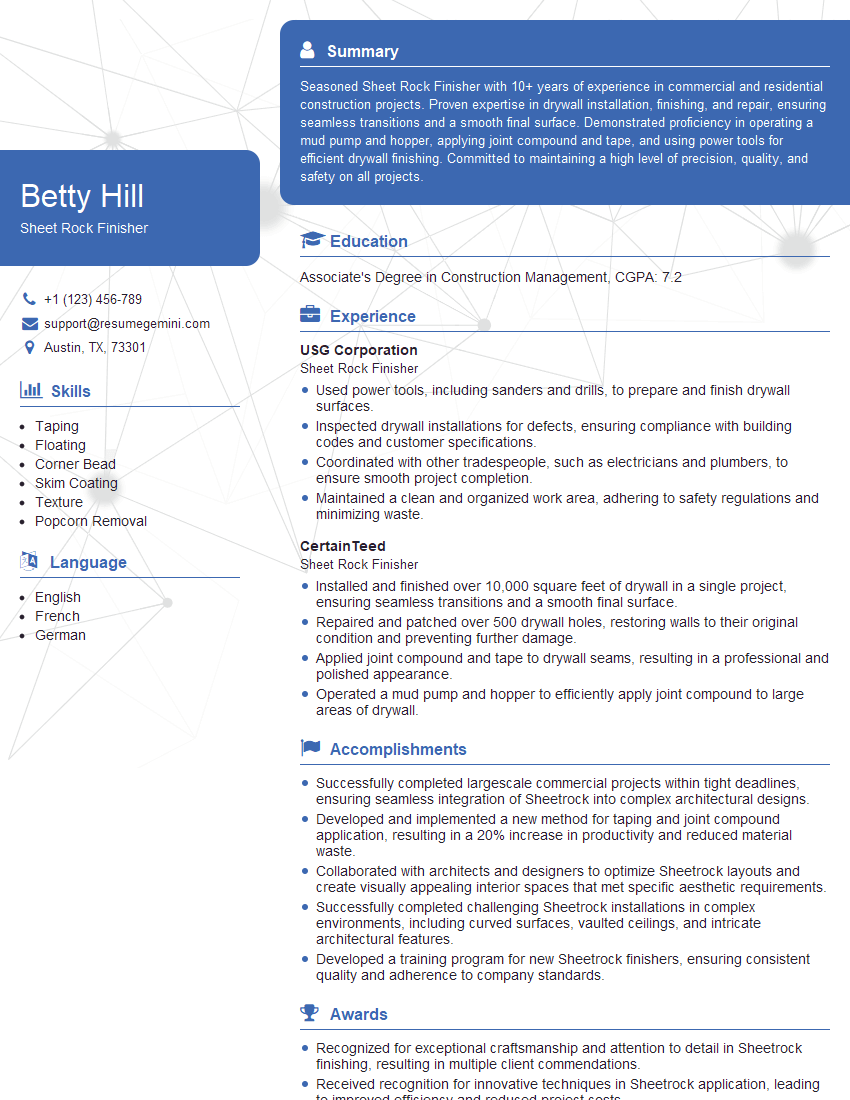

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Rock Finisher

1. Can you describe the steps involved in installing drywall?

- Measure and cut the drywall to fit the wall or ceiling.

- Apply drywall adhesive to the studs or joists.

- Lift the drywall into place and secure it with screws or nails.

- Tape and mud the joints between the drywall panels.

- Sand the joints smooth.

- Apply a primer and paint to the drywall.

2. What are the different types of drywall and their uses?

Regular Drywall

- Most common type of drywall

- Used in most residential and commercial buildings

- Available in different thicknesses and sizes

Green Drywall

- Also referred to as moisture-resistant drywall

- Contains a water-repellent additive

- Used in areas with high humidity, such as bathrooms and kitchens

Purple Drywall

- Also known as impact-resistant drywall

- Contains a fiberglass mesh reinforcement

- Used in areas where there is a risk of impact, such as garages and children’s rooms

Type X Drywall

- Fire-resistant drywall

- Contains a gypsum core and a fiberglass mat

- Used in areas where fire resistance is required, such as stairwells and elevator shafts

3. What are the common mistakes made by drywall finishers and how can they be avoided?

- Not measuring and cutting the drywall properly

- Not applying drywall adhesive evenly

- Not securing the drywall properly

- Not taping and mudding the joints properly

- Not sanding the joints smooth

- Not applying a primer and paint to the drywall

4. What tools and equipment are essential for a drywall finisher?

- Drywall lift

- Drywall saw

- Drywall knife

- Taping knife

- Mud pan

- Corner trowel

- Sander

- Primer

- Paint

5. What safety precautions should be taken when working as a drywall finisher?

- Wear a dust mask to avoid inhaling drywall dust.

- Wear safety glasses to protect your eyes from flying debris.

- Wear gloves to protect your hands from cuts and abrasions.

- Use a drywall lift to avoid lifting heavy drywall panels manually.

- Be aware of your surroundings and avoid tripping over cords or tools.

6. What are the key qualities of a successful drywall finisher?

- Attention to detail

- Patience

- Accuracy

- Physical strength

- Ability to work independently

- Teamwork skills

- Communication skills

7. How do you stay up-to-date on the latest drywall finishing techniques?

- Read trade magazines

- Attend industry workshops and conferences

- Network with other drywall finishers

- Experiment with new techniques

8. What is your experience with different types of drywall finishing projects?

- Residential drywall finishing

- Commercial drywall finishing

- Industrial drywall finishing

- Historical drywall finishing

9. How do you handle working on large drywall finishing projects?

- Break the project down into smaller tasks.

- Prioritize the tasks and focus on one task at a time.

- Coordinate with other trades to ensure a smooth workflow.

- Use efficient tools and equipment to speed up the process.

- Maintain a clean and organized work area.

10. How do you ensure the quality of your drywall finishing work?

- Inspect the drywall and framing before starting work.

- Follow the manufacturer’s instructions for installing and finishing drywall.

- Use high-quality materials and tools.

- Take your time and pay attention to detail.

- Get feedback from the customer and make adjustments as needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Rock Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Rock Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet Rock Finishers, also known as drywall finishers or drywall installers, play a crucial role in the construction and finishing of buildings by installing and smoothing drywall panels. Here are their key job responsibilities:

1. Drywall Installation

Sheet Rock Finishers are responsible for installing drywall panels onto walls, ceilings, and other surfaces. This involves measuring, cutting, and fitting the panels accurately to ensure a seamless and even surface.

- Install drywall panels according to blueprints and specifications.

- Use specialized tools and equipment, such as drywall lifts and panel cutters.

2. Drywall Finishing

After the drywall panels are installed, Sheet Rock Finishers apply joint compound to fill in gaps and smooth out the surface. They use various techniques and materials, such as taping, floating, and sanding, to achieve a uniform and professional finish.

- Apply joint compound to conceal seams and imperfections.

- Use joint tape and other materials to reinforce and strengthen joints.

- Sand and smooth the surface to create a seamless appearance.

3. Texturing and Painting

Depending on the desired finish, Sheet Rock Finishers may also apply textures to the drywall surface, such as knockdown or orange peel. They may also be responsible for painting the finished drywall, ensuring an even and professional application.

- Apply textures to create decorative effects on walls and ceilings.

- Prime and paint drywall surfaces according to specifications.

- Maintain a clean and organized work area.

4. Inspection and Quality Control

Sheet Rock Finishers are responsible for inspecting their work to ensure it meets industry standards and customer requirements. They may use levelers, tape measures, and other tools to verify the accuracy of their installations.

- Inspect finished surfaces for imperfections and defects.

- Ensure that installations meet building codes and regulations.

- Maintain a high level of craftsmanship and quality.

Interview Tips

To help you ace your interview for a Sheet Rock Finisher position, here are some valuable tips and preparation hacks:

1. Research the Company and the Industry

Take the time to thoroughly research the construction company you’re applying to and the drywall industry as a whole. Learn about their projects, techniques, and safety protocols. This knowledge will demonstrate your interest and enthusiasm for the role.

- Visit the company’s website and social media pages.

- Read industry publications and articles.

2. Practice Your Skills

Before the interview, practice your drywall finishing skills. This could involve applying joint compound, taping, or texturing on a spare piece of drywall. The interviewer may ask you to demonstrate your abilities, so being prepared will give you an edge.

- Set up a practice area in your garage or workshop.

- Gather the necessary tools and materials.

3. Highlight Your Experience and Qualifications

In your interview, emphasize your relevant experience and qualifications. Quantify your accomplishments whenever possible, using specific examples to demonstrate your abilities. If you have experience in different aspects of drywall finishing, such as installation, finishing, or painting, be sure to mention them.

- Prepare a portfolio of your work, if available.

- Be prepared to discuss your knowledge of drywall materials and techniques.

4. Showcase Your Safety Awareness

Construction sites can be hazardous environments, so employers place a high value on safety consciousness. During the interview, demonstrate your understanding of safety protocols and your commitment to following them. Mention any safety certifications you have obtained, and emphasize your attention to detail when it comes to safety.

- Be familiar with OSHA regulations and industry best practices.

- Discuss your experience with using personal protective equipment (PPE).

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sheet Rock Finisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!