Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Sheet Rock Installation Helper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Sheet Rock Installation Helper so you can tailor your answers to impress potential employers.

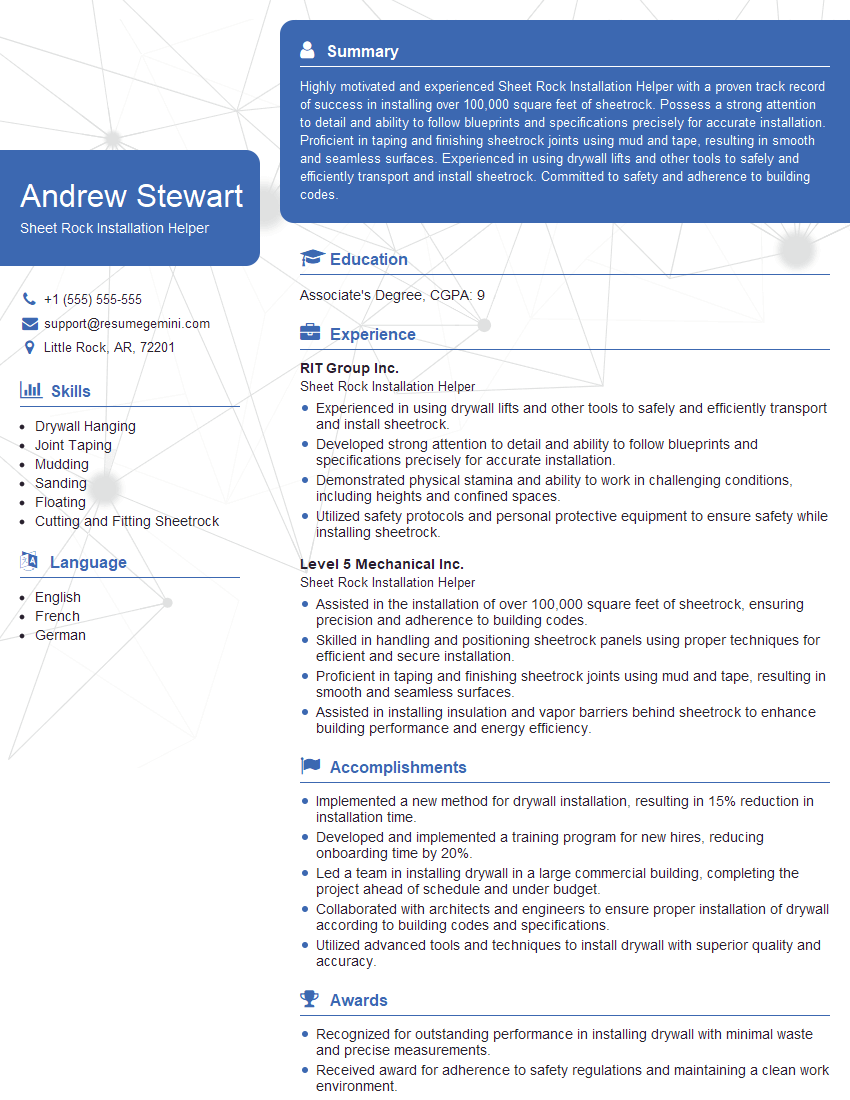

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Rock Installation Helper

1. How do you ensure a seamless transition between old and new drywall surfaces?

- Sand the edges of the new drywall to create a smooth surface.

- Apply a thin layer of joint compound to the edges of both the old and new drywall.

- Use a feathering knife to blend the joint compound into the surrounding surfaces.

- Sand the area again to create a smooth, seamless transition.

2. What are the different types of drywall seams and how do you treat each one?

Butt joints

- Butt joints are created when two edges of drywall are placed directly against each other.

- To treat a butt joint, apply a thin layer of joint compound to the joint and smooth it out with a knife.

Tapered joints

- Tapered joints are created when the edges of two pieces of drywall are tapered.

- To treat a tapered joint, apply a thin layer of joint compound to the joint and use a knife to feather the edges into the surrounding drywall.

Corner joints

- Corner joints are created when two pieces of drywall meet at a corner.

- To treat a corner joint, apply a thin layer of joint compound to the joint and use a knife to create a smooth, straight edge.

3. Explain the process of installing drywall over a curved surface?

- Score the drywall along the curve using a utility knife.

- Bend the drywall along the score line and secure it to the framing using drywall screws.

- Apply joint compound to the seams and smooth it out with a knife.

- Sand the area to create a smooth, seamless surface.

4. What are the different types of drywall tools and how do you use them?

- Drywall saw: Used to cut drywall to size.

- Drywall knife: Used to apply and smooth joint compound.

- Drywall screw gun: Used to drive drywall screws into the framing.

- Stud finder: Used to locate studs behind drywall.

- Level: Used to ensure that drywall is installed level.

- Tape measure: Used to measure and cut drywall.

5. When applying joint compound, why is it important to let each coat dry completely before sanding?

- Sanding before the joint compound is completely dry can cause the compound to tear or crumble.

- Waiting for each coat to dry ensures that the compound is fully set and will provide a smooth, durable finish.

6. How do you repair a hole in drywall?

- Cut a patch of drywall that is slightly larger than the hole.

- Apply a thin layer of joint compound to the edges of the patch and the surrounding drywall.

- Place the patch over the hole and secure it with drywall screws.

- Apply joint compound to the seams and smooth it out with a knife.

- Sand the area to create a smooth, seamless surface.

7. What are the safety precautions that should be taken when installing drywall?

- Wear a dust mask to avoid inhaling drywall dust.

- Wear safety glasses to protect your eyes from flying debris.

- Use a ladder or scaffolding to reach high areas.

- Be careful when using sharp tools.

- Follow all manufacturer’s instructions.

8. What is the purpose of mudding drywall and how is it done?

- Purpose: Mudding is the process of applying joint compound to drywall seams and nail holes to create a smooth, even surface.

- Process:

- Apply a thin layer of joint compound to the seam or nail hole.

- Use a drywall knife to smooth out the compound.

- Let the compound dry completely.

- Sand the area to create a smooth, seamless surface.

9. How do you determine the appropriate thickness of drywall to use for a particular application?

- Consider the following factors:

- Fire resistance rating: Thicker drywall provides better fire resistance.

- Soundproofing: Thicker drywall provides better soundproofing.

- Structural support: Thicker drywall provides better structural support for hanging shelves and other objects.

- Cost: Thicker drywall is more expensive.

- Consult with a building professional to determine the appropriate thickness of drywall for your specific application.

10. What are some common mistakes to avoid when installing drywall?

- Installing drywall over uneven framing: This can lead to cracks and uneven surfaces.

- Not letting joint compound dry completely before sanding: This can cause the compound to tear or crumble.

- Sanding too much: This can weaken the drywall and make it more susceptible to damage.

- Using too much joint compound: This can lead to a lumpy, uneven surface.

- Not priming the drywall before painting: This can cause the paint to peel or chip.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Rock Installation Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Rock Installation Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet Rock Installation Helpers support Sheet Rock Installers in the construction of drywall interiors, ceilings, and soffits. They are responsible for assisting with the loading, unloading, and positioning of drywall materials, as well as cleaning up the work area. Sheet Rock Installation Helpers also operate power tools and maintain a safe work environment.

1. Assist with Drywall Installation

Sheet Rock Installation Helpers assist Sheet Rock Installers with the installation of drywall by loading, unloading, and positioning drywall sheets. They also help to cut and fit drywall sheets, and to apply joint compound and tape.

- Load, unload, and position drywall sheets

- Cut and fit drywall sheets

- Apply joint compound and tape

2. Prepare Work Area

Sheet Rock Installation Helpers prepare the work area by clearing away furniture and other objects, and by protecting floors and walls from damage. They also set up scaffolding and other equipment.

- Clear away furniture and other objects

- Protect floors and walls from damage

- Set up scaffolding and other equipment

3. Clean Up Work Area

Sheet Rock Installation Helpers clean up the work area by removing debris, sweeping floors, and wiping down surfaces. They also dispose of waste materials and pack up equipment.

- Remove debris

- Sweep floors

- Wipe down surfaces

- Dispose of waste materials

- Pack up equipment

4. Operate Power Tools

Sheet Rock Installation Helpers operate power tools, such as drills, saws, and sanders, to cut, fit, and install drywall. They also use power tools to clean up the work area.

- Operate drills

- Operate saws

- Operate sanders

- Use power tools to clean up the work area

Interview Tips

To prepare for your interview for a Sheet Rock Installation Helper position, you should research the company and the position, practice answering common interview questions, and dress professionally. You should also be prepared to talk about your experience and skills, and to answer questions about your availability and schedule.

1. Research the Company and the Position

Before your interview, you should research the company and the position. This will help you to understand the company’s culture and values, as well as the specific requirements of the position. You can research the company on its website, Glassdoor, and other online resources.

- Research the company’s website

- Research the company on Glassdoor

- Research the company on other online resources

2. Practice Answering Common Interview Questions

You should also practice answering common interview questions. This will help you to feel more confident and prepared during your interview. Some common interview questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with drywall installation?

- What is your availability and schedule?

3. Dress Professionally

You should dress professionally for your interview. This shows the interviewer that you are serious about the position and that you respect the company. You should wear clean, pressed clothes and avoid wearing casual clothing, such as jeans and t-shirts.

- Wear clean, pressed clothes

- Avoid wearing casual clothing

4. Be Prepared to Talk About Your Experience and Skills

During your interview, you should be prepared to talk about your experience and skills. You should highlight your experience with drywall installation, as well as your other relevant skills, such as operating power tools and cleaning up work areas.

- Highlight your experience with drywall installation

- Highlight your other relevant skills

5. Be Prepared to Answer Questions About Your Availability and Schedule

The interviewer may also ask you questions about your availability and schedule. You should be prepared to answer these questions honestly and accurately. If you have any scheduling conflicts, you should be prepared to discuss them with the interviewer.

- Answer questions about your availability honestly and accurately

- Be prepared to discuss any scheduling conflicts

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sheet Rock Installation Helper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!