Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Sheet Rock Installer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Sheet Rock Installer so you can tailor your answers to impress potential employers.

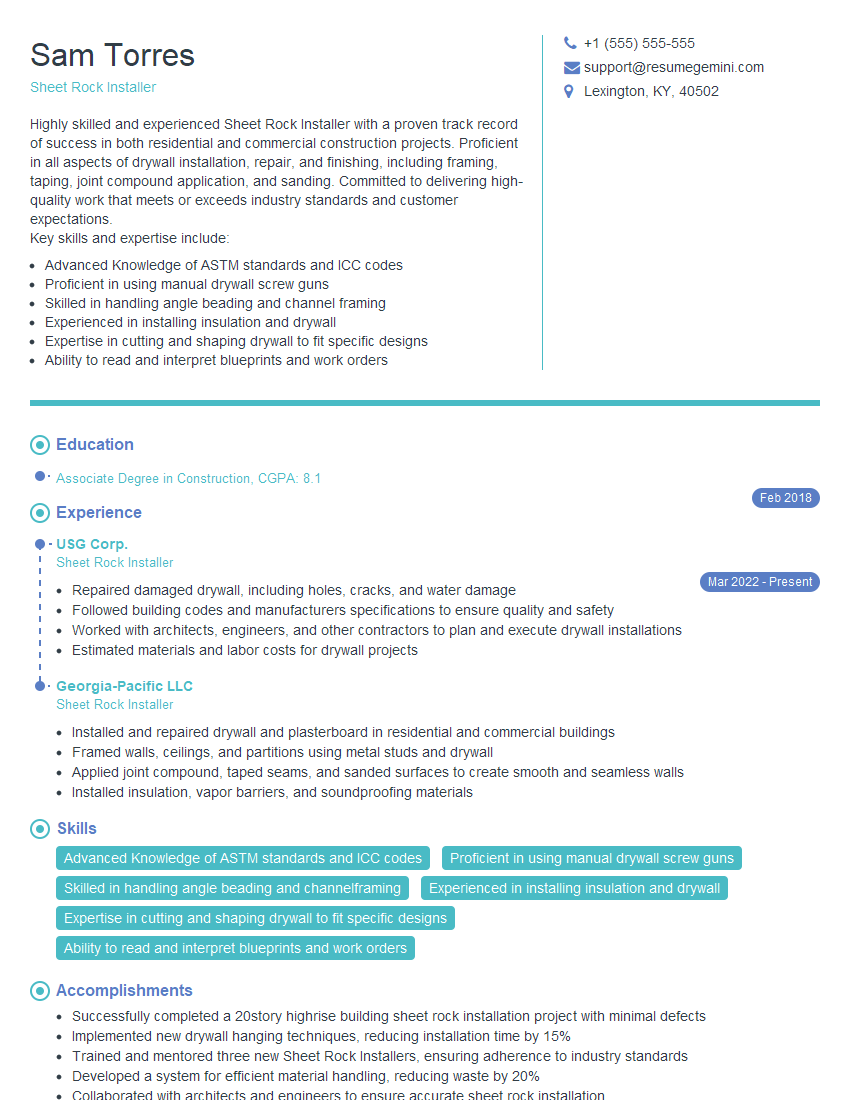

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Rock Installer

1. What are the different types of drywall and their specific applications?

There are several types of drywall, each with its own unique characteristics and applications:

- Regular drywall: The most common type of drywall, used for interior walls and ceilings in residential and commercial buildings.

- Greenboard: Water-resistant drywall, used in bathrooms, kitchens, and other areas prone to moisture.

- Fire-rated drywall: Provides resistance to fire, used in areas where fire safety is a concern, such as stairwells and firewalls.

- Soundproof drywall: Reduces noise transmission, used in recording studios, home theaters, and other areas where sound control is important.

- Lightweight drywall: Lighter and easier to handle than regular drywall, used in areas where weight is a concern, such as high-rise buildings and suspended ceilings.

2. Describe the process of installing drywall, step by step.

Hanging the drywall

- Measure and cut the drywall to fit the wall or ceiling.

- Apply drywall adhesive to the studs or joists.

- Lift the drywall into place and secure it with drywall screws.

Finishing the drywall

- Apply drywall tape to the joints between the drywall panels.

- Apply a thin coat of joint compound over the tape and smooth it out.

- Apply a second coat of joint compound and sand it smooth.

- Apply a final coat of joint compound and sand it to a fine finish.

3. What are the different tools and materials required for drywall installation?

- Drywall lift: Used to lift and install drywall panels.

- Drywall screws: Used to secure drywall to studs or joists.

- Drywall tape: Used to reinforce the joints between drywall panels.

- Joint compound: Used to fill and smooth the joints between drywall panels.

- Putty knife: Used to apply and smooth joint compound.

- Sanding sponge: Used to smooth the joint compound.

- Measuring tape: Used to measure and cut drywall.

- Utility knife: Used to cut drywall.

4. How do you ensure that the drywall is installed level and plumb?

To ensure that the drywall is installed level and plumb, use a level and a plumb bob throughout the installation process:

- Hanging the drywall: Use a level to make sure that the drywall panels are hung straight and level.

- Finishing the drywall: Use a plumb bob to make sure that the corners are plumb.

5. How do you repair damaged drywall?

To repair damaged drywall, follow these steps:

- Remove the damaged section: Cut out the damaged section of drywall using a utility knife.

- Install a drywall patch: Cut a piece of drywall to fit the hole and secure it in place with drywall screws.

- Apply joint compound: Apply joint compound over the patch and smooth it out.

- Sand the patch: Sand the patch smooth after the joint compound has dried.

6. What are some common problems that you may encounter during drywall installation and how do you resolve them?

- Uneven drywall surface: This can be caused by uneven studs or joists. To resolve it, use a sanding sponge to smooth out the surface.

- Cracked drywall joints: This can be caused by improper installation or movement of the building. To resolve it, apply new joint tape and joint compound over the cracks.

- Nail pops: This can be caused by nails that were not driven in deep enough. To resolve it, drive the nails in deeper or replace them with drywall screws.

- Water damage: This can be caused by leaks or flooding. To resolve it, remove the damaged drywall and replace it with new drywall.

7. What is the proper way to cut drywall?

To cut drywall properly, follow these steps:

- Measure and mark the drywall: Use a measuring tape and a pencil to mark the area that you want to cut.

- Score the drywall: Use a utility knife to score the drywall along the marked lines.

- Snap the drywall: Place the drywall on a sawhorse or other support and snap it along the scored lines.

8. What is the best way to prevent drywall damage?

To prevent drywall damage, follow these tips:

- Protect drywall from moisture: Do not store drywall in damp areas and avoid exposing it to water or moisture.

- Handle drywall carefully: Be careful not to drop or damage drywall during installation.

- Avoid overloading drywall: Do not hang heavy objects on drywall without proper support.

- Repair drywall promptly: If drywall is damaged, repair it promptly to prevent further damage.

9. What are some of the latest trends in drywall installation?

- Use of pre-finished drywall: This type of drywall comes with a factory-applied finish, which saves time and labor during installation.

- Installation of drywall on curved surfaces: This technique is becoming increasingly popular for creating unique and stylish interiors.

- Use of soundproofing drywall: This type of drywall reduces noise transmission, making it ideal for use in homes, offices, and other buildings where sound control is important.

10. What are your strengths and weaknesses as a drywall installer?

Some of my strengths as a drywall installer include my attention to detail, my ability to work independently, and my strong work ethic. I am also proficient in all aspects of drywall installation, from hanging and finishing to repairing and replacing drywall.

One of my weaknesses is that I am not always the fastest drywall installer. However, I believe that my attention to detail and commitment to quality make up for this.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Rock Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Rock Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet Rock Installers, also known as drywall installers, are responsible for installing and finishing drywall in various types of buildings, including residential homes, commercial properties, and industrial facilities. Their primary objective is to ensure that the drywall is installed correctly and meets the required specifications.

1. Drywall Installation

Install drywall panels onto walls, ceilings, and other surfaces using appropriate tools and techniques.

- Measure and cut drywall to fit specific areas.

- Secure drywall to studs or framing using nails, screws, or adhesives.

2. Joint Treatment

Apply joint compound to drywall seams and corners to create a smooth and seamless surface.

- Apply tape to drywall joints to reinforce and prevent cracking.

- Cover tape with multiple layers of joint compound and sand to smooth the surface.

3. Finishing

Apply primer and paint to drywall surfaces to provide a finished and professional appearance.

- Sand drywall surfaces to remove any imperfections or rough spots.

- Apply primer to prepare drywall for painting.

- Paint drywall using rollers, brushes, or spray guns.

4. Other Duties

Perform other related tasks as required, such as cleaning up work areas, maintaining tools and equipment, and assisting with other construction projects.

- Inspect drywall for defects and make necessary repairs.

- Follow building codes and regulations related to drywall installation.

- Work as part of a team or independently in various work environments.

Interview Tips

Preparing for an interview for a Sheet Rock Installer position requires a combination of technical knowledge, industry experience, and effective communication skills. Here are some valuable tips to help candidates ace their interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and current projects. Research the specific Sheet Rock Installer position to understand the job requirements and responsibilities.

- Identify the company’s areas of specialization and target projects.

- Review the job description thoroughly to tailor your answers to the specific requirements.

2. Highlight Relevant Experience and Skills

Emphasize your previous experience in drywall installation, highlighting your proficiency in joint treatment, finishing, and other related tasks. Quantify your accomplishments and provide specific examples of your work.

- Discuss the types of projects you have worked on and the techniques you have utilized.

- Showcase your ability to meet deadlines and work efficiently in a fast-paced environment.

3. Demonstrate Knowledge of Safety Protocols

Sheet Rock installation involves working with sharp tools and heavy materials in various environments. Emphasize your knowledge of safety protocols and practices to protect yourself and others.

- Explain how you ensure proper ventilation and wear appropriate safety gear.

- Discuss any safety certifications or training you have received.

4. Prepare for Industry-Specific Questions

Interviewers may ask industry-specific questions to assess your technical competence. Be prepared to discuss drywall types, joint compound applications, and finishing techniques.

- Familiarize yourself with different types of drywall, their properties, and uses.

- Review various joint compound products and their appropriate applications.

5. Practice Your Communication Skills

Effective communication is crucial for Sheet Rock Installers to collaborate with other tradespeople and clients. Practice your communication skills to articulate your ideas clearly and professionally.

- Prepare concise and informative answers to common interview questions.

- Use industry-specific terminology and demonstrate your knowledge of the field.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sheet Rock Installer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.