Are you gearing up for an interview for a Sheeter Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Sheeter Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

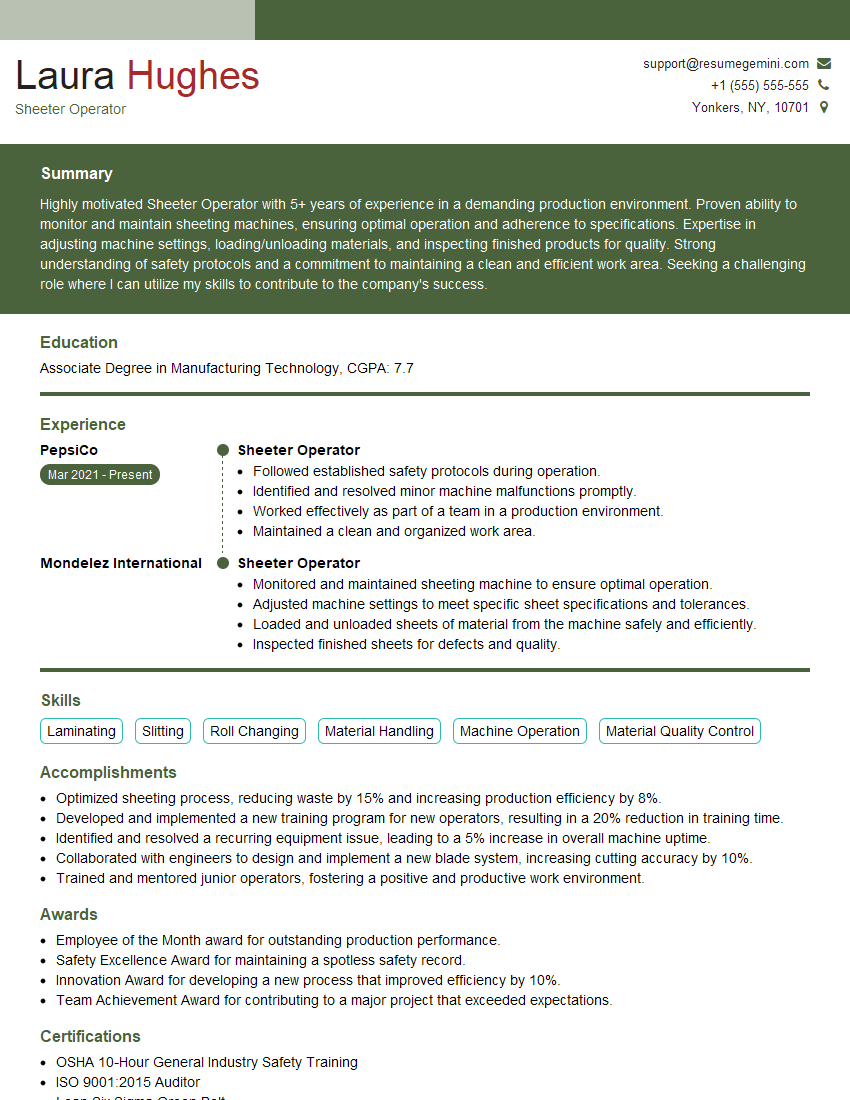

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheeter Operator

1. Explain the process of operating a sheeting machine, step by step?

The process of operating a sheeting machine involves several steps to ensure efficient and accurate production.

- Material Preparation: Unroll the material roll and feed it into the machine’s unwinder, ensuring proper alignment.

- Tension Control: Adjust the tension rollers to maintain the desired material tension, avoiding wrinkles or breaks.

- Knife Adjustment: Position the cutting knives precisely based on the required sheet size and adjust their sharpness for clean cuts.

- Thickness Calibration: Calibrate the machine’s thickness gauge to measure and control the sheet thickness accurately.

- Cutting: Initiate the cutting process, ensuring smooth and consistent material flow through the knives.

- Sheet Stacking: Collect the cut sheets and stack them neatly on a pallet or designated area.

2. What are the common types of sheeting machines and their applications?

Types of Sheeting Machines:

- Rotary Sheeter: High-speed machines with circular knives, ideal for large-volume production of sheets.

- Guillotine Sheeter: Uses a guillotine-like action to cut sheets, suitable for low to medium volume production.

- Plough Sheeter: Employs adjustable plough blades to cut sheets, offering flexibility and short setup times.

Applications:

- Paper and Board Industry: Cutting paper, cardboard, and other materials into sheets for packaging, printing, and stationery.

- Plastics Industry: Producing plastic sheets for thermoforming, packaging, and construction.

- Metal Industry: Cutting metal sheets for fabrication, stamping, and other metalworking processes.

3. How do you maintain a sheeting machine for optimal performance?

- Regular Cleaning: Remove dust, debris, and material scraps from the machine regularly to prevent malfunctions.

- Blade Sharpening: Keep the cutting knives sharp to ensure clean cuts and prevent material tearing.

- Tension Monitoring: Regularly check and adjust the tension rollers to maintain optimal material tension.

- Calibration Checks: Perform periodic calibration checks on the thickness gauge and other critical components to ensure accuracy.

- Lubrication: Lubricate moving parts according to the manufacturer’s recommendations to reduce friction and wear.

4. What are the safety precautions you observe when operating a sheeting machine?

- Proper Training: Undergo thorough training and follow all safety protocols before operating the machine.

- Protective Gear: Wear appropriate safety gear, including gloves, safety glasses, and hearing protection.

- Guard Adherence: Ensure all machine guards are in place and functioning correctly.

- Clearance from Moving Parts: Maintain a safe distance from moving machine parts, especially during operation.

- Emergency Stop Awareness: Familiarize yourself with the location of the emergency stop button and know how to use it in case of emergencies.

5. How do you troubleshoot common problems encountered during sheeting machine operation?

- Sheet Tearing: Check blade sharpness, tension settings, and material quality for defects.

- Uneven Sheet Thickness: Calibrate the thickness gauge and inspect the material for thickness variations.

- Machine Jamming: Clear material debris, check for paper misalignment, and adjust tension settings.

- Excessive Vibration: Inspect machine components for wear or misalignment, and check tension settings.

- Electrical Faults: Check power supply, wiring, and electrical connections. If unable to resolve, contact an electrician.

6. What measures do you take to minimize waste during sheeting operations?

- Precision Cutting: Ensure accurate knife adjustment and machine calibration to minimize material loss during cutting.

- Optimized Sheet Layout: Plan sheet layout to maximize sheet yield and minimize off-cuts.

- Scrap Recycling: Collect scrap materials for recycling purposes, reducing waste and environmental impact.

- Regular Maintenance: Maintain machine components to prevent malfunctions and ensure smooth operation, reducing unnecessary waste.

7. How do you ensure the quality of sheets produced by the sheeting machine?

- Visual Inspection: Regularly inspect sheets for defects, including tears, wrinkles, or thickness variations.

- Measurement Verification: Use measuring tools to verify sheet dimensions and thickness, ensuring they meet specifications.

- Machine Monitoring: Monitor machine sensors and gauges to detect any deviations from optimal operating parameters.

- Quality Control Standards: Follow established quality control standards to ensure consistency and accuracy in sheet production.

8. How do you work effectively in a team environment as a sheeting machine operator?

- Communication: Maintain open communication with team members, sharing information and seeking assistance when needed.

- Collaboration: Cooperate with colleagues to optimize production processes, troubleshoot issues, and maintain a safe work environment.

- Support: Provide support to other team members, including training, knowledge sharing, and assisting with tasks.

- Flexibility: Adapt to changing production demands and be willing to take on different responsibilities as required.

9. What are your strengths and weaknesses as a sheeting machine operator?

Strengths:- Proficient in operating various types of sheeting machines.

- Strong attention to detail and commitment to producing high-quality sheets.

- Excellent troubleshooting skills to resolve machine malfunctions efficiently.

- Experience in implementing waste reduction measures to optimize production.

- Limited experience with automation and advanced machine controls.

- Can be slightly slower than average in setting up and calibrating machines.

10. Why are you interested in this sheeting machine operator position?

I am eager to join your organization as a sheeting machine operator because I am confident that my skills and experience align well with the requirements of this role. My proven ability to operate various types of sheeting machines, combined with my strong work ethic and commitment to quality, makes me an ideal candidate for this position.

Furthermore, I am enthusiastic about the prospect of contributing to your team. I believe that my expertise in waste reduction measures and troubleshooting will add value to your operations. I am eager to learn from experienced professionals and contribute to the company’s success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheeter Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheeter Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Sheeter Operator is responsible for operating and maintaining a sheeting machine, which cuts paper into sheets of a specific size. Key job responsibilities include:

1. Operating the Sheeting Machine

Loading paper rolls onto the machine and threading them through the cutting blades.

- Setting the machine to cut the paper to the desired size and thickness.

- Monitoring the machine during operation to ensure that it is cutting the paper accurately and efficiently.

2. Maintaining the Sheeting Machine

Performing regular maintenance on the machine, such as cleaning, lubricating, and adjusting the cutting blades.

- Troubleshooting and repairing minor problems with the machine.

- Reporting any major problems with the machine to the supervisor.

3. Quality Control

Inspecting the finished sheets of paper to ensure that they meet the required quality standards.

- Measuring the sheets to ensure that they are the correct size and thickness.

- Checking for any defects, such as tears, wrinkles, or uneven cuts.

4. Safety

Following all safety procedures when operating the sheeting machine.

- Wearing appropriate safety gear, such as gloves and safety glasses.

- Keeping the work area clean and free of debris.

- Reporting any unsafe conditions to the supervisor.

Interview Tips

To prepare for an interview for a Sheeter Operator position, it is important to:

1. Research the Company and the Position

Learn about the company’s history, products, and services. Research the specific job requirements and responsibilities so that you can tailor your answers to the interviewer’s questions.

- Visit the company’s website and social media pages.

- Read industry news and articles to learn about the latest trends and technologies.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you can expect to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in a clear and concise manner.

- Use the STAR method to answer questions. This method involves describing the Situation, Task, Action, and Result of your experience.

- Be prepared to provide specific examples of your skills and experience.

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, as being late can reflect poorly on your punctuality and reliability.

- Choose clothing that is clean, pressed, and appropriate for the office environment.

- Arrive at the interview location at least 10 minutes early.

4. Be Enthusiastic and Confident

Employers are looking for candidates who are enthusiastic about the position and confident in their abilities. Be yourself and let your personality shine through.

- Make eye contact with the interviewer and speak clearly and confidently.

- Ask questions about the position and the company to show your interest.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sheeter Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.