Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Shell Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Shell Machine Operator so you can tailor your answers to impress potential employers.

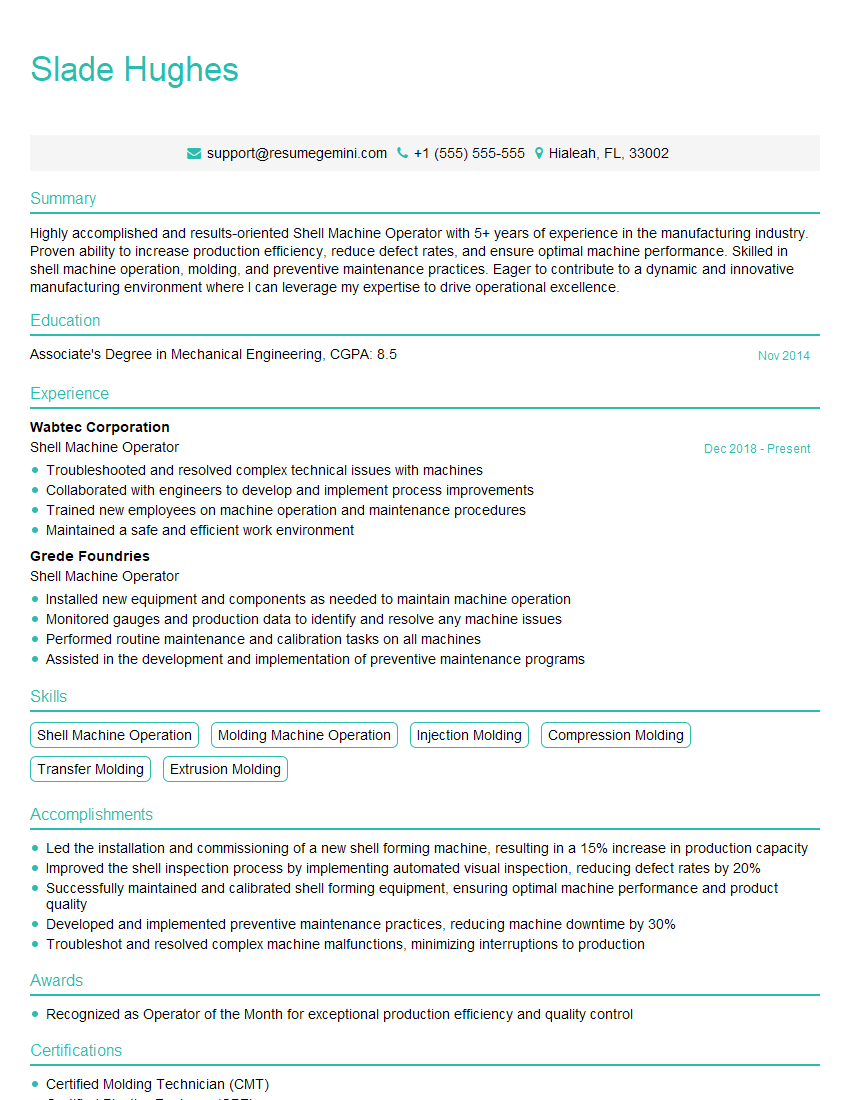

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shell Machine Operator

1. What are the key responsibilities of a Shell Machine Operator?

As a Shell Machine Operator, I would be responsible for:

- Operating and maintaining shell molding machines

- Setting up and adjusting machine parameters

- Monitoring the molding process and making adjustments to ensure quality

- Inspecting finished shells for defects

- Maintaining a clean and safe work area

2. Describe the different types of shell molding machines.

There are two main types of shell molding machines:

Blow machines

- Use a pressurized air stream to force hot sand into a mold, creating a shell mold

- Produce shells that are thin and uniform in thickness

- Suitable for small to medium-sized castings

Shooter machines

- Use a gravity-fed system to drop sand into a mold

- Produce shells that are thicker and less uniform in thickness

- Suitable for large and complex castings

3. What are the safety precautions that must be followed when operating a shell molding machine?

When operating a shell molding machine, I would adhere to the following safety precautions:

- Wear appropriate personal protective equipment, including gloves, safety glasses, and earplugs

- Follow lockout/tagout procedures when servicing or repairing the machine

- Never operate the machine with guards removed

- Be aware of the location of emergency stop buttons

- Keep the work area clean and free of tripping hazards

4. How do you troubleshoot common problems that occur with shell molding machines?

Some common problems that can occur with shell molding machines include:

- Sand sticking to the pattern: This can be caused by improper resin/catalyst ratio, insufficient binder, or excessive moisture in the sand

- Cracked or broken shells: This can be caused by improper setting of machine parameters, worn mold pins, or excessive shell thickness

- Defective castings: This can be caused by improper mold setup, incorrect pouring temperature, or insufficient cooling time

5. What maintenance tasks are required to keep a shell molding machine in good working condition?

Regular maintenance is essential to keep a shell molding machine in good working condition and prevent costly breakdowns. Some important maintenance tasks include:

- Daily: Clean the machine, check for leaks, and lubricate moving parts

- Weekly: Inspect the mold pins, sand hopper, and resin/catalyst system

- Monthly: Perform a thorough inspection of the machine, including electrical and mechanical components

6. How do you ensure the quality of the shells produced by the machine?

To ensure the quality of the shells produced by the shell molding machine, I would:

- Regularly monitor the machine’s parameters, such as temperature and pressure

- Inspect the shells visually for any defects, such as cracks or voids

- Perform destructive testing on a sample of shells to assess their strength and durability

- Maintain a log of all quality checks and any corrective actions taken

7. What is the role of a Shell Machine Operator in a foundry?

As a Shell Machine Operator in a foundry, I would be responsible for:

- Operating and maintaining shell molding machines

- Producing high-quality shells for use in the casting process

- Working with other foundry personnel to ensure smooth production

- Following safety procedures and maintaining a clean and organized work area

8. What are the different types of resins used in shell molding?

The two main types of resins used in shell molding are:

- Phenolic resins: These resins are low in cost, produce strong shells, and have good thermal stability

- Furan resins: These resins are more expensive than phenolic resins, but they offer better resistance to heat and chemicals

9. How do you determine the correct resin/catalyst ratio for a particular shell molding application?

The correct resin/catalyst ratio is critical to producing high-quality shells. To determine the correct ratio, I would:

- Refer to the manufacturer’s specifications for the resin and catalyst

- Perform tests to determine the optimal ratio for the specific application

- Monitor the shells during the curing process to ensure that they are properly cured

10. What are the key factors that affect the quality of a shell mold?

The key factors that affect the quality of a shell mold include:

- The quality of the sand

- The resin/catalyst ratio

- The curing time and temperature

- The pattern and mold equipment

- The operator’s skill and experience

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shell Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shell Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Shell Machine Operators are responsible for operating and maintaining shell molding machines. They ensure that the machines are running smoothly and efficiently, and that the shells produced meet the required specifications.

1. Set up and operate shell molding machines

Shell Machine Operators set up and operate shell molding machines according to the manufacturer’s instructions. They ensure that the machines are properly calibrated and that the correct settings are used for the type of shell being produced.

- Load the machine with the proper materials.

- Set the machine’s controls to the correct settings.

- Start the machine and monitor its operation.

2. Inspect shells for defects

Shell Machine Operators inspect shells for defects, such as cracks, voids, or other imperfections. They use a variety of tools and techniques to identify and correct any defects.

- Use a flashlight to inspect the shells for cracks or voids.

- Use a micrometer to measure the thickness of the shells.

- Use a hardness tester to check the hardness of the shells.

3. Maintain shell molding machines

Shell Machine Operators maintain shell molding machines by performing regular inspections and cleaning. They also lubricate the machines and replace worn parts as needed.

- Clean the machine’s exterior and interior surfaces.

- Lubricate the machine’s moving parts.

- Inspect the machine’s electrical system for any loose connections or damaged wires.

4. Troubleshoot and repair shell molding machines

Shell Machine Operators troubleshoot and repair shell molding machines when they experience problems. They use their knowledge of the machines and their experience to identify and fix the problems quickly and efficiently.

- Identify the source of the problem.

- Repair or replace the damaged parts.

- Test the machine to ensure that it is operating properly.

Interview Tips

Preparing for an interview can be daunting, but it can be made easier by following a few simple tips.

1. Research the company and the position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture and values, and it will also help you to answer questions about the position and your qualifications.

- Visit the company’s website.

- Read articles about the company in the news.

- Talk to people who work for the company.

2. Practice answering interview questions

One of the best ways to prepare for an interview is to practice answering interview questions. This will help you to become more comfortable with the interview process and it will also help you to develop your answers to common questions.

- Make a list of common interview questions.

- Practice answering the questions out loud.

- Ask a friend or family member to give you feedback on your answers.

3. Dress appropriately

First impressions matter, so it is important to dress appropriately for your interview. This means dressing in clothes that are clean, pressed, and professional. You should also avoid wearing clothes that are too revealing or too casual.

- Wear a suit or dress pants and a button-down shirt.

- Make sure your clothes are clean and pressed.

- Avoid wearing clothes that are too revealing or too casual.

4. Be on time

Punctuality is important, so make sure you arrive for your interview on time. This shows that you are respectful of the interviewer’s time and that you are taking the interview seriously.

- Plan your route to the interview in advance.

- Leave plenty of time for traffic and parking.

- Arrive for your interview 5-10 minutes early.

Next Step:

Now that you’re armed with the knowledge of Shell Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Shell Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini