Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Shell Molding Roller Blast Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

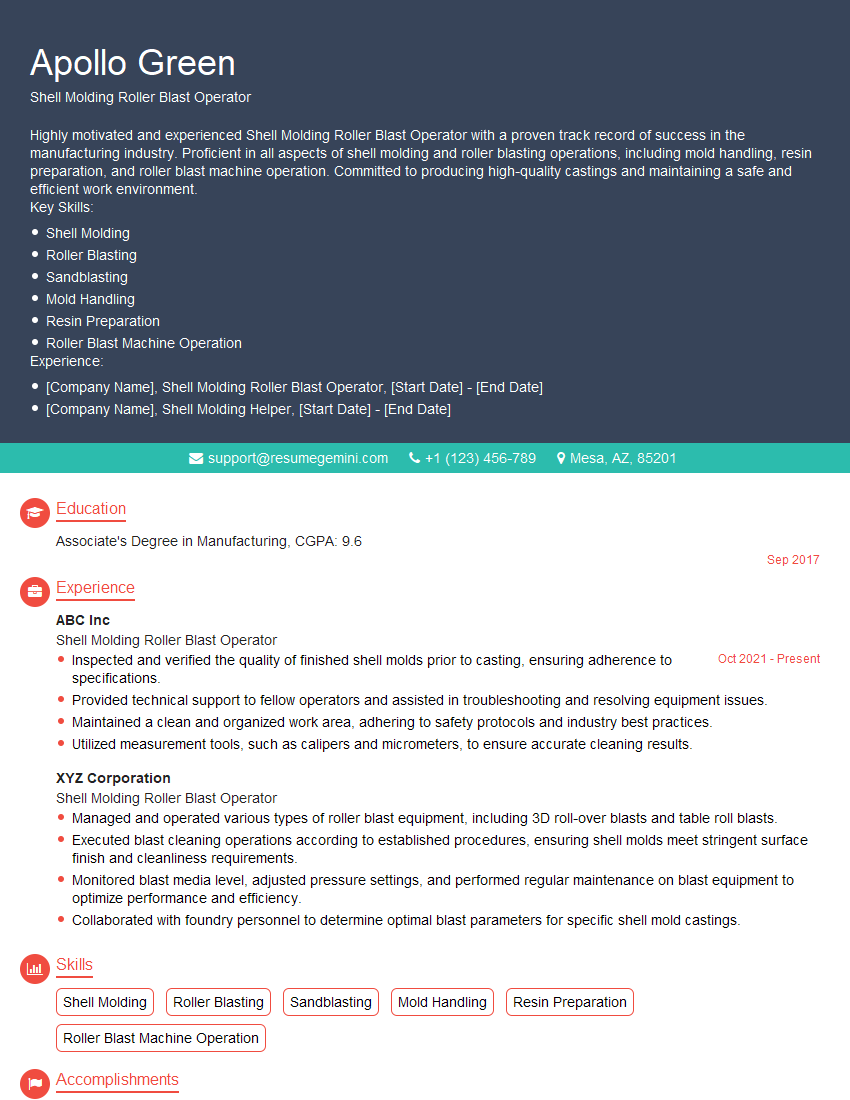

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shell Molding Roller Blast Operator

1. Describe the key steps involved in the shell molding roller blast process?

The key steps in the shell molding roller blast process are as follows:

- Prepare the pattern and create the shell mold

- Load the mold onto the roller blast machine

- Select the appropriate blast media and settings

- Start the blasting process and monitor the progress

- Unload the mold and inspect the results

2. Explain the role of the abrasive media in the shell molding roller blast process?

- The abrasive media removes excess sand and other contaminants from the surface of the mold

- It creates a smooth, uniform surface that is ideal for casting

- It helps to strengthen the mold and prevent defects

3. How do you determine the appropriate blast media and settings for a given application?

The appropriate blast media and settings will vary depending on the type of mold, the desired surface finish, and the thickness of the mold. I typically start with a medium-grit abrasive and adjust the settings as needed. I also consult with the manufacturer’s recommendations for specific applications.

4. What are the potential hazards associated with the shell molding roller blast process?

The potential hazards associated with the shell molding roller blast process include:

- Exposure to dust and other contaminants

- Eye injuries from flying debris

- Hearing loss from the noise of the machinery

- Skin irritation from the abrasive media

5. What safety precautions should be taken when operating a shell molding roller blast machine?

The following safety precautions should be taken when operating a shell molding roller blast machine:

- Wear appropriate personal protective equipment, including a respirator, safety glasses, gloves, and hearing protection

- Ensure that the machine is properly grounded and that all guards are in place

- Never operate the machine unattended

- Follow the manufacturer’s operating instructions carefully

6. How do you maintain a shell molding roller blast machine?

Regular maintenance is essential to keep a shell molding roller blast machine operating safely and efficiently. I typically perform the following maintenance tasks:

- Inspect the machine for any damage or wear and tear

- Clean the machine and remove any accumulated dust or debris

- Lubricate all moving parts

- Check the blast media level and add more as needed

7. What are some of the common problems that can occur with a shell molding roller blast machine?

Some of the common problems that can occur with a shell molding roller blast machine include:

- The machine may not start

- The blast media may not be flowing properly

- The mold may not be blasted evenly

- The machine may be making excessive noise

8. How do you troubleshoot and repair a shell molding roller blast machine?

When troubleshooting and repairing a shell molding roller blast machine, I typically start by checking the following:

- The power supply

- The air pressure

- The blast media level

- The condition of the blast media

- The condition of the nozzles

9. What are the key quality control checks that should be performed on a shell molding roller blast machine?

The following key quality control checks should be performed on a shell molding roller blast machine:

- The surface finish of the mold

- The thickness of the mold

- The uniformity of the blast

- The presence of any defects

10. How do you ensure that the shell molding roller blast process is operating at peak efficiency?

To ensure that the shell molding roller blast process is operating at peak efficiency, I perform the following tasks:

- Monitor the machine’s performance regularly

- Make adjustments to the blast media and settings as needed

- Perform regular maintenance on the machine

- Train new operators on the proper operation of the machine

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shell Molding Roller Blast Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shell Molding Roller Blast Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Shell Molding Roller Blast Operator plays a vital role in the production of castings utilizing the shell molding process. Their key responsibilities encompass:

1. Blast and Clean Shell Molds

Using a roller blast machine, they remove any residual sand and impurities from the surface of the shell molds.

- Operates and adjusts blast machine settings (speed, pressure, angle, media flow) to achieve optimal cleaning results.

- Monitors the quality of the blasted molds to ensure they meet specifications.

2. Inspect and Maintain Equipment

They ensure the proper functionality and safety of the roller blast machine and related equipment.

- Inspects and maintains the blast machine, including blast wheels, nozzles, and dust collection systems.

- Identifies and reports any equipment issues or malfunctions for timely repairs.

3. Handle and Transport Molds

They safely handle and transport shell molds throughout the molding process.

- Loads and unloads molds from the roller blast machine using appropriate lifting equipment.

- Stacks and stores molds properly to prevent damage.

4. Maintain a Clean and Safe Work Area

They adhere to safety protocols and maintain a clean and organized work environment.

- Sweeps and cleans the work area regularly to remove debris and potential hazards.

- Follows safety procedures, including wearing appropriate personal protective equipment (PPE).

Interview Tips

To ace the interview for a Shell Molding Roller Blast Operator position, consider the following preparation tips:

1. Research the Company and Industry

Demonstrate your interest in the company and the role by thoroughly researching their website and industry trends.

2. Review Key Job Responsibilities

Familiarize yourself with the key job responsibilities as outlined above. Prepare specific examples that showcase your relevant skills and experience.

- Highlight your experience in operating and maintaining blast machines.

- Emphasize your attention to detail and commitment to quality.

3. Practice Common Interview Questions

Anticipate common interview questions related to your skills, experience, and work ethic. Prepare concise and compelling answers.

- Explain your understanding of the shell molding process.

- Describe your experience in handling and transporting materials.

4. Highlight Safety and Attention to Detail

Emphasize your commitment to safety and your meticulous attention to detail. These qualities are crucial in this role.

- Share examples of your proactive approach to safety in previous roles.

- Provide instances where your detail-oriented nature contributed to successful outcomes.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Shell Molding Roller Blast Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Shell Molding Roller Blast Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.