Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Shell Sieve Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

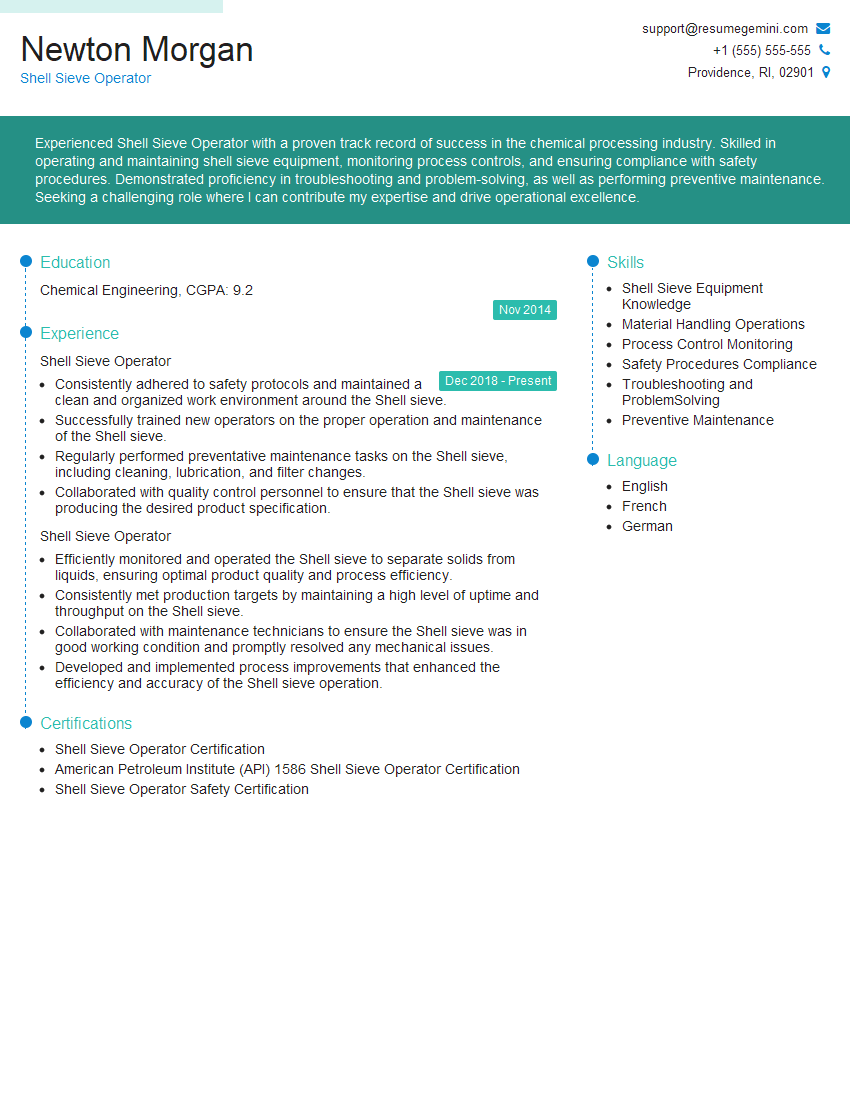

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shell Sieve Operator

1. What are the key responsibilities of a Shell Sieve Operator?

The primary responsibilities of a Shell Sieve Operator include:

- Preparing and operating sieve machines as per established procedures.

- Monitoring the sieve process and making adjustments as needed.

- Inspecting incoming and outgoing materials to ensure quality.

- Maintaining cleanliness and safety in the work area.

- Communicating effectively with colleagues and supervisors.

2. Describe the different types of sieve machines used in the oil and gas industry.

Centrifugal Sieve Machines

- High-speed rotation force separates particles.

- Used for fine particle separation.

Vibrating Sieve Machines

- Vibrations move particles along the screen.

- Can handle a wide range of materials.

Gyratory Sieve Machines

- Circular motion in two planes.

- High efficiency and accuracy.

3. What factors affect the efficiency of sieve operations?

- Condition of the sieve screens

- Appropriate mesh size selection

- Distribution of particles in the feed

- Feed rate and moisture content

- Mechanical condition of the sieve machine

4. What quality control procedures are used in sieve operations?

- Visual inspection of incoming and outgoing materials

- Sieve analysis and particle size measurement

- Calibration and maintenance of sieve machines

- Record-keeping and documentation

- Adherence to standard operating procedures (SOPs)

5. What safety precautions are essential for Shell Sieve Operators?

- Wearing appropriate personal protective equipment (PPE)

- Following lockout/tagout procedures

- Maintaining a clean and organized work area

- Reporting any unsafe conditions or equipment malfunctions

- Training and certification in relevant safety protocols

6. Describe the maintenance procedures for a Shell sieve machine.

- Daily inspections and cleaning

- Regular lubrication and greasing

- Screen replacement as needed

- Inspection and adjustment of vibration or gyratory mechanisms

- Calibration and testing to ensure accuracy

7. How do you handle process upsets or equipment failures during sieve operations?

- Identify the cause of the issue promptly.

- Isolate the affected equipment and stop the process if necessary.

- Notify the supervisor and consult with colleagues.

- Implement corrective actions to address the issue.

- Document the incident and communicate lessons learned.

8. What are the common troubleshooting techniques used in sieve operations?

- Checking for blockages or leaks in the feed system.

- Inspecting the sieve screens for damage or wear.

- Adjusting the feed rate or sieve vibration amplitude.

- Monitoring the power consumption and temperature of the sieve machine.

- Consulting manufacturer’s manuals and technical support.

9. Explain how the sieve process contributes to the overall efficiency of the production process.

- Ensuring the removal of contaminants and impurities.

- Producing products with optimal particle size distribution.

- Improving downstream processes and equipment performance.

- Reducing maintenance costs and downtime.

- Meeting quality standards and customer specifications.

10. Describe your experience with troubleshooting and resolving issues related to sieve operations.

In my previous role as a Shell Sieve Operator, I encountered various issues and successfully resolved them, ensuring uninterrupted production and product quality. One notable instance involved a sudden drop in sieve efficiency. Through a systematic troubleshooting process, I identified a blockage in the feed hopper and promptly cleared it. By applying my technical knowledge and problem-solving skills, I restored the sieve’s performance to optimal levels, minimizing downtime and maintaining process efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shell Sieve Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shell Sieve Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Shell Sieve Operators play a crucial role in ensuring the efficient and safe operation of separation processes in the oil and gas industry. Their primary responsibility involves overseeing the operation of shell sieves, which are used to remove solids from liquids or gases.

1. Sieve Operation Management

Shell Sieve Operators are responsible for monitoring and controlling the operation of shell sieves. This includes adjusting process parameters such as flow rates, temperatures, and pressures to optimize sieve performance and ensure the desired separation results.

- Monitor and adjust sieve parameters to ensure optimal performance

- Troubleshoot and resolve any issues that may arise during sieve operation

2. Solids Removal

A key task of Shell Sieve Operators is to remove solids from liquids or gases. They ensure that the sieve is functioning properly to remove the desired amount of solids.

- Operate and maintain shell sieves to remove solids from liquids or gases

- Ensure the proper disposal of removed solids

3. Equipment Maintenance

Shell Sieve Operators are responsible for the maintenance and upkeep of shell sieves. This includes cleaning, inspecting, and repairing sieves to ensure they are in good working order.

- Perform routine maintenance and repairs on shell sieves

- Ensure that sieves are properly calibrated and maintained

4. Quality Control

Shell Sieve Operators are responsible for monitoring the quality of the output from shell sieves. They ensure that the separated liquids or gases meet the desired specifications.

- Monitor and control the quality of the output from shell sieves

- Take corrective actions to ensure that the output meets specifications

Interview Tips

Preparing for an interview for a Shell Sieve Operator position requires thorough research and effective communication skills. Here are some tips to help candidates ace the interview:

1. Research the Company and Industry

Familiarize yourself with Shell’s operations, values, and the oil and gas industry as a whole. This will demonstrate your interest and understanding of the field.

- Visit Shell’s website and review their company profile, news, and sustainability reports

- Read industry publications and articles to stay up-to-date on current trends and technologies

2. Practice Your Technical Skills

Be prepared to discuss your technical knowledge and experience in sieve operation, solids removal, and equipment maintenance. Review key concepts and prepare examples to illustrate your expertise.

- Describe your experience with different types of shell sieves and their applications

- Discuss your understanding of process control and optimization techniques

3. Highlight Your Safety and Quality Mindset

Shell places a high priority on safety and quality. Emphasize your strong safety consciousness and commitment to maintaining high standards in your work.

- Share examples of your adherence to safety protocols and risk management practices

- Explain how you ensure the quality of your output and take corrective actions when necessary

4. Prepare for Behavioral Questions

Interviews often include behavioral questions to assess your teamwork, problem-solving, and communication skills. Be ready to provide specific examples that demonstrate these qualities.

- Describe a time you worked effectively in a team to achieve a project goal

- Explain how you handled a challenging situation and resolved it successfully

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Shell Sieve Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.